After the acquisition of Phenix Systems, 3D Systems has been slow to roll out its metal 3D printing technology, an issue raised in a class action lawsuit against the company. Nevertheless, the company has been making progress and, today, 3D Systems announced the availability of their newest system, the ProX DMP 320.

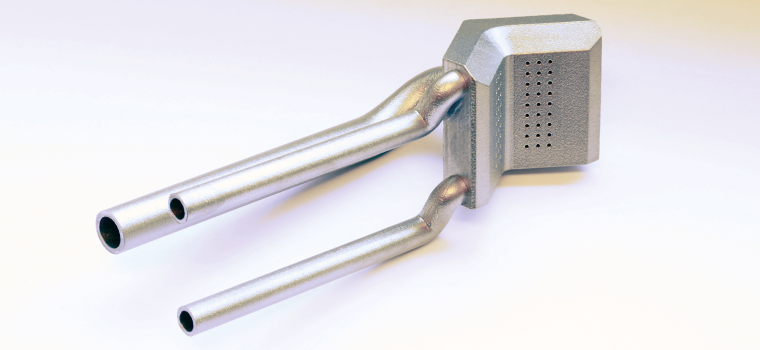

The ProX DMP 320 is designed to be a high precision, high throughput laser sintering metal 3D printer capable of handling itanium, stainless steel, and nickel super alloy. Built with exchangeable manufacturing modules, the ProX DMP 320 is meant to allow for quick material change. To achieve the repeatability much sought after in mainstream manufacturing, the machine has preset build parameters based off of almost half-a-million builds. The ProX DMP 320 features a large build volume of 275mm x 275mm x 420mm with two configurations available, one meant for stainless steel and the other nickel super alloy. The machine offers centralized maintenance management, reduced argon gas use, and support for a serial manufacturing workflow.

Mark Wright, Executive Vice President and Chief Operating Officer at 3D Systems, said of the new product, “With the ProX DMP 320, we’ve leveraged our collective expertise in metal additive manufacturing to pair best-in-class productivity and repeatability with exceptional outcomes in key industrial materials. We’ve been working closely with leading customers through extensive beta testing of this machine and the feedback we have received distinguishes this printer as one primed to transform expectations for timelines, process and results.”

3D Systems has already established one beta tester, Direct Metal Printing service bureau 3rd Dimension. Bob Markley, Founder and Chief Executive Officer at 3rd Dimension, says of the machine, “As beta system partners, we have been relying on the ProX DMP 320 to make titanium parts and are impressed by the high throughput, ease of use, consistency of output, and overall part quality. Combined with our ProX 200 and ProX 300, we are able to provide our customers with the optimal part, in the optimal metal, to meet the demands of each and every application—no matter how specialized.”

Perhaps a little late for Euromold and formnext, the ProX DMP 320 is on display at CES at the 3D Systems booth. Unfortunately, I won’t be at CES this year, but it would be interesting to see how their booth compares to those created under the leadership of former CEO Avi Reichental. Given the company’s recent decision to discontinue the Cube 3 3D printer and consolidate the Cubify group, I would think that their booth might be a bit more modest this year.