After a year of working with 3D Printing Industry, I’ve learned a great deal about 3D printing, human progress and myself as a writer. The readers have been so thoughtful and appreciative in their feedback regarding the site and the 3DPI team has been so thoughtful and appreciative of having me on board as a writer. So, I want to say thank you to the other members of 3D Printing Industry and to our readers. I also want to say thanks to my wife, Danielle, for encouraging and embracing my 3D printed path. She was the one who suggested I write about the technology in the first place and literally gave me the idea for my first piece about 3DP.

As is becoming a 3DPI tradition, we’ve got these lists of our top 5 3D printing applications of the year. So, for the first time, here are my top 5 bits of 3D printing news that I’ve come across since beginning with the company.

Laybrick

Laybrick

I’m putting Laybrick on this list because I wasn’t at 3DPI last year to make a top 5 on which to put Laywoo-D3. I think that both materials opened many outsiders’ eyes to the potential for 3D printing. To people I speak with about the technology, or who have seen my own 3D printer, 3D printing is equated with monochromatic, plastic, low resolution junk. You can only make so many things out of plastic, which has this artificial quality about it. But when you can start making things out of wood or “cement”, then you’re onto something. Vases once made out of PLA have an unrefined, sharp quality about them. When made out of chalk filament, like LAYBRICK, the unfinished nature of the material is a textural property that contributes to the piece’s character.

3D Printed Livers

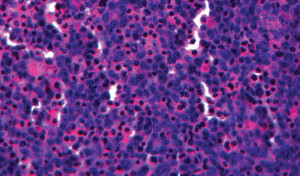

At Thanksgiving, my wife and I were talking to my family members, some of whom are in the medical field, about Organovo. When Danielle told them about 3D assays of liver cells and that they were more viable than 2D assays, my godmother, a nurse, immediately understood the potential of the company’s 3D-printed liver cells, saying, “Yes, flat cells don’t live very long, but if they have volume, they can be used for drug testing.”

This year, the bioprinting company completed its first clinical test of their liver cell assay, applying liver-toxic tylenol to their tissues. The tests demonstrated that the 3D printed liver cells responded as an actual liver might, displaying the typical toxicity seen in a liver exposed to acetaminophen. With proof that their tissues might be valuable clinical tools, Organovo is ready to go ahead offering their 3D printed liver assays to drug companies to begin testing next year.

The use of such a product will bring experimental medicines to market much faster because they will provide data of how a drug might work in the human system, which was previously difficult to achieve without giving humans experimental drugs directly. The ability to produce a whole range of test cells for other organs would make it possible to, one day, bypass animal testing and, if it reached its full realization, could pave the way for printable organs. With a detriment of organ donors in supply and a list of more than 120,000 people in need of a transplant in the United States, 3D printed organs could save the lives of 18 people a day in the US alone. Until then, however, we’ll have to wait for more people to overcome superstition and sign the backs of their Drivers Licenses.

Affordable, Open Source Metal Printing

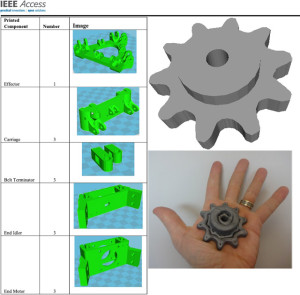

Just before the close of this year, my favourite university lab, the Pearce Research Group at Michigan Tech, released plans for an open source, 3D metal printer. The 3D metal printer was constructed similarly to any other RepRap only, instead of an extruder for plastic, the group used a gas-metal arc welder that melted bits of steel into a three-dimensional object. The total cost of building the machine was $1,192.93.

The output of the 3D metal printer wasn’t that polished, but the implications were profound. Electron beam melting machines and other industrial 3D metal printers run at close to half a million dollars, making the barrier to entry impossible to overcome for all but the big corporations. An affordable 3D metal printer could give individuals access to produce useful parts (not just plastic toys). The research group also pointed out that such a device could run on recycled aluminum, which would reduce waste.

LEAP Engine

The 3D printed fuel nozzles, showing the support of large manufacturers for 3D printing, do provide evidence of the power of intricate and efficient 3D printed components. More importantly, they’re a symbol of the power that large companies have to change the world. As it stands, 15% is not a big percentage, but if all multinational corporations take it upon themselves to embrace social responsibility, not as a marketing gimmick and a means of saving $1 million per plane, but as a moral imperative, such giants could actually save the planet from global devastation.

Imagine if all of the large corporations decided to do something about such immense problems as climate change, if they pushed that number from a 15% reduction in CO2 emissions to a 90% or even 100% reduction, if, instead of pursuing dollar wealth, they pursued planetary wealth and made a concerted effort to reduce greenhouse gasses, switch our infrastructures over to ecologically sustainable technologies, and actually made the world better for everyone in it. The LEAP engine is good idea, but, if they took it far enough, it could actually matter to people.

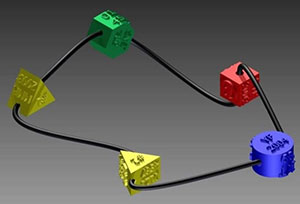

3D Printers for Peace

This leads me to the last bit of 3D printing news of the year, the 3D Printers for Peace contest, also put on by the Pearce Research Group at Michigan Tech. After the release of Defense Distributed’s 3D-printed Liberator pistol, 3D printing was quickly becoming equated with 3D printed guns in the mass media. To counter the violent potential of the technology, Pearce’s group started the contest to encourage people to think of the immense positive potential of 3D printing. The contestant whose entry would do the most to reduce global suffering, in the minds of the judges, would win a Type A Series 1 3D printer.

The contest, I believe, frames 3D printing and humanity’s efforts in the way in which I believe that it needs to be framed. We could go on making things in order to earn fame, fortune and power, but once any or all of those superficial goals are achieved, what’s left? One can only earn so much of that stuff before one realizes how meaningless and arbitrary it really is. World peace, on the other hand, is a project that requires much more effort and ingenuity than earning some pointless dollar figure. If you could achieve world peace, than you could really say that you’d done something with your life.

And, once we’ve got world peace, all you’d have left to do would be to figure out the meaning of life.

Happy New Year, everyone!

Feature Image Source: thepartydj on Thingiverse