Coming off of the success of their Big Delta 3D printer, one of the ultimate goals of the World Advanced Saving Project to 3D print sustainable homes for those in need, WASP is already onto its next project and product. The Italian manufacturer has announced the production of the WASP Delta Top 1609, a DLP 3D printer that will be released into the public domain for non-commercial use.

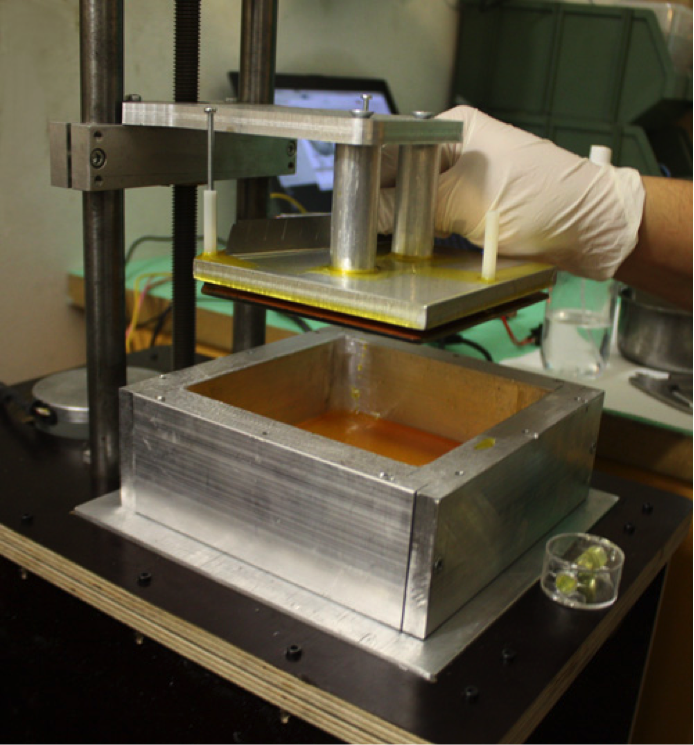

Believing that they could produce a low-cost machine capable of printing layer resolutions of .08 mm, WASP embarked on their DLP printer three years ago, but were hindered by a few problems in the design of the machine, in which prints were getting stuck to the printbed. Working on the bottom-up DLP approach typically implemented by DLP machines, in which the projector was placed below the resin vat and projected upwards, they sought similar solutions to ensure that their prints wouldn’t stick to the bed, applying specialty anti-adhesive materials to the printbed.

This, however, makes clean-up an issue for users and, according to WASP, decreases the success rate of the prints. In a press release, they write, “The part’s adhesion to the silicon layer is also an issue. In spite of the silicon’s anti-adherence properties, the part tends to remain attached due to the suction effect. With use the vat become more opaque and consumed, thus attaching to the print and causing a higher percentage of print failures, as the print attaches to the projection plane and not to the print plate. Low quality 3D printers can have failure rates as high as 50%.”

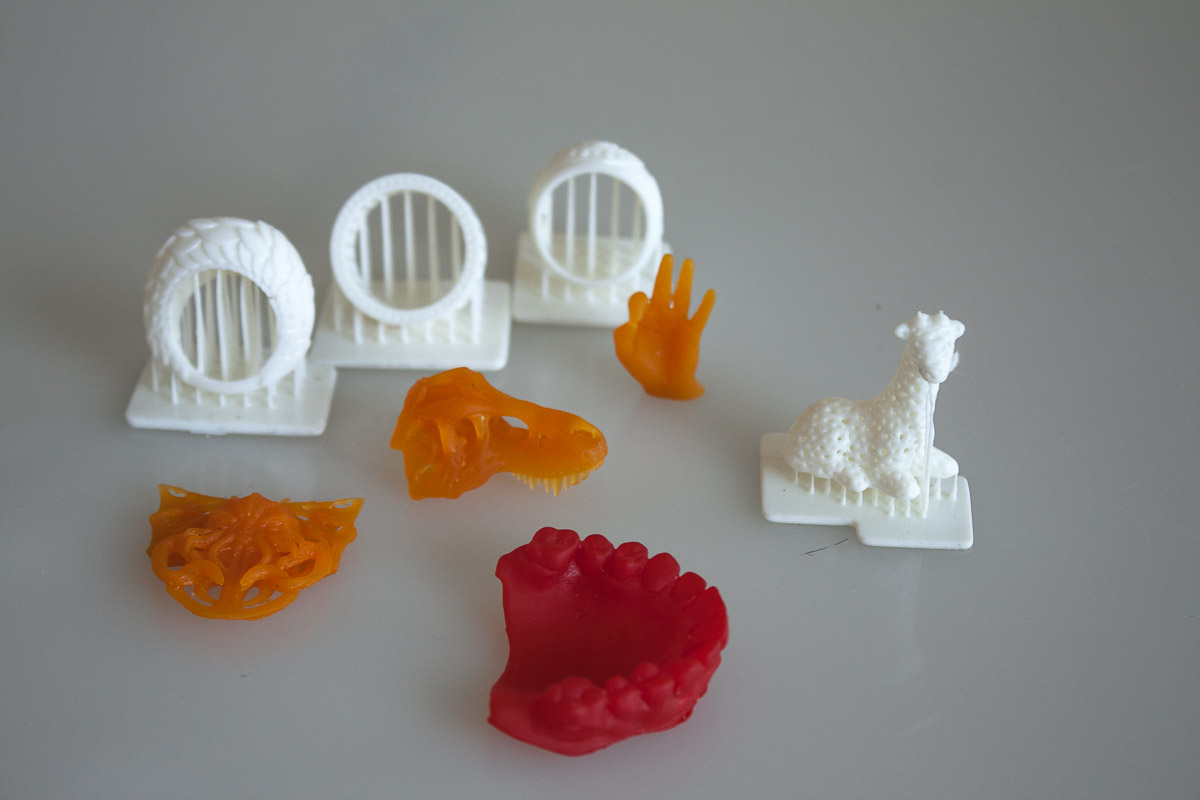

Then, a few months ago, they found their solution with a top-down DLP process, in which the printbed is located below a resin vat and brought up, into the light, so to speak. The introduction of a watertight lid to the resin vat also makes it easier to clean-up. Together, these eliminated the adhesion issues, reducing the complexity of the process and increasing its cleanliness. Finally, WASP added a filter for removing the odor from the photopolymerization process.

WASP plans to release the WASP Delta Top 1609 in the coming months, with what they say is the best quality/price ration possible with the machine. Until then, they plan to show off their new system at Rome Maker Faire, from October 16 – 18.

Update/Correction 10/2/2-15: I’ve been told that the correct name of WASP’s new DLP 3D printer is the Delta Top 1609. Specs for the printer can be found at WASP’s new US site, launched as the company begins distributing in the United States. Among the specs are the machine’s layer resolution of .025 > 0.1 mm, max printing speed of 30 mm/h (8 mm/h for greater resolution), and cylindrical print volume of 88 around x 158mm tall (3.5″ x 6.2″).