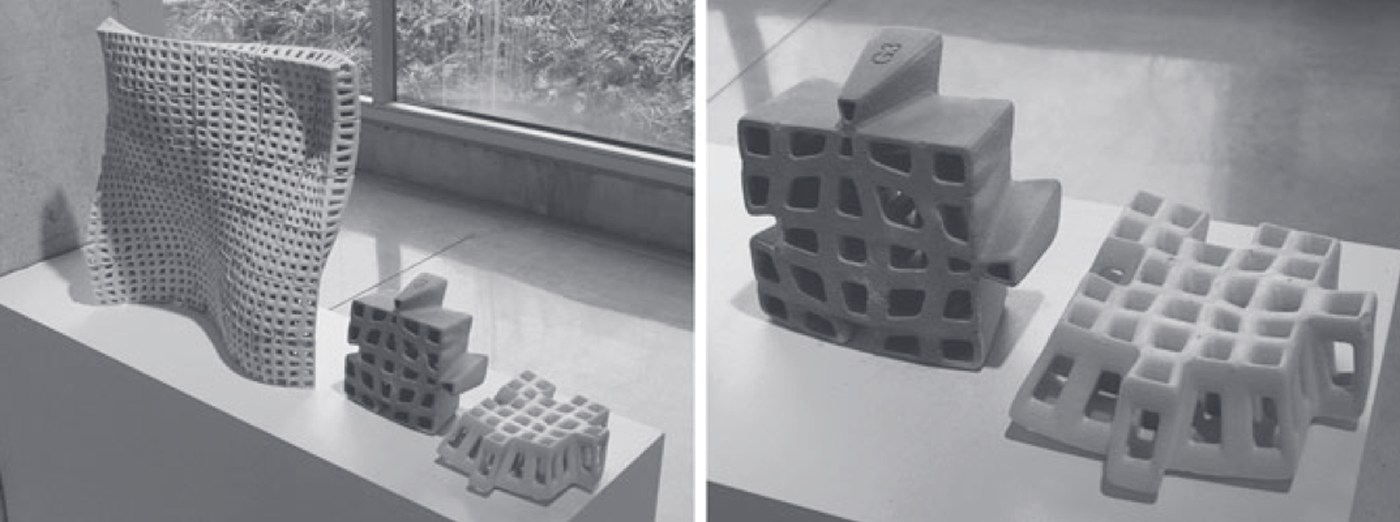

3D printed construction is starting to become a fully-fledged industry, with multiple methods of 3D printing buildings being developed across the world. While most focus on large gantry systems for extruding concrete into three-dimensional shapes, we’ve also seen tiny robots do the printing. Now, researchers from Cornell University and Jenny Sabin Studio have invented a new method for building large structures in 3D. It involves 3D printed, interlocking blocks that the researchers call PolyBricks.

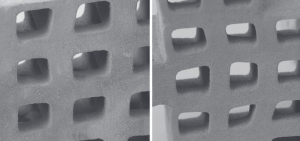

Current 3D printing technology limits the size at which one can build. Using a component – based system, part to whole relationships and geometric specificity in terms of local orientation, we have generated a series of digital tools that allow us to create large – scale objects from a smaller print bed. Using computational design techniques, we have built a series of custom digital tools to facilitate the embedding of multiple data sets. Many wall systems require an array of materials and a significant level of human labor to construct. Our system operates using only a single material and can be put together simply and easily. The development of human large – scale 3D-printed assemblies is difficult using current 3D printing technology and those systems that can print at the human and building scales frequently exhibit very low resolution in terms of mesh fineness.

The group behind the project has yet to assemble a building with their PolyBricks, but their concept has great potential. Forget 3D printed shoes, this year is shaping up to be the year of 3D printed buildings!

Source: Softpedia