Move over China, Behrokh Khoshnevis, and the Canal House, here’s a fella who’s 3D printing a building in his own garage! Though there’s been recent news of a Chinese company 3D printing homes in 24 hours, Dr. Khoshnevis at USC has been promising 3D concrete printing for at least a few years, and a Dutch design firm is slowly 3D printing a plastic building in Amsterdam, Andrey Rudenko is in the process of testing his own 3D construction process from the confines of his Minnesotan home.

Rudenko, a contractor with a background in architecture and engineering, is currently at the experimentation stage of his project. He’s spent the last year building a 3D concrete printer in his two-car garage, gradually scaling up his project to the point where he can print a two-story home. The architect says that this has been a long time in the making, “My concrete printing experience dates back to about 20 years ago, but at that point, advanced computers and software were not available for the type of technology I was looking to build. Thus, it wasn’t until a couple years ago that I came across the RepRap project and started working on this machine again. It took about a year to build as well as develop the special concrete mixes.”

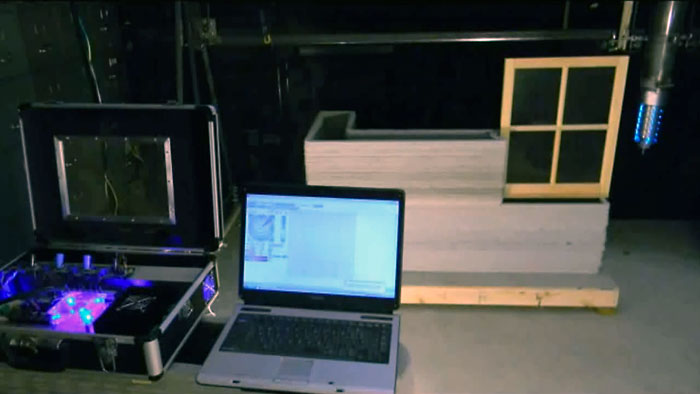

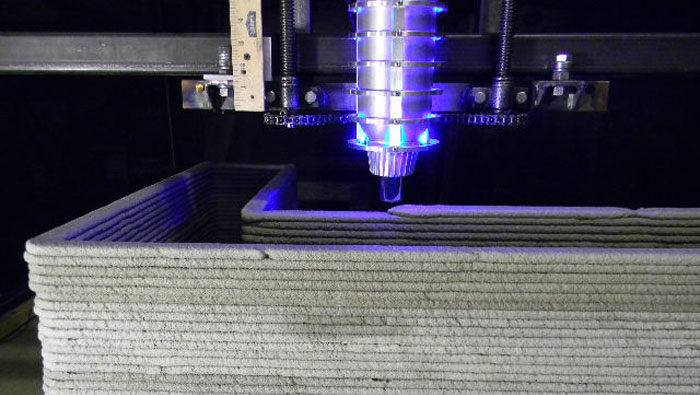

Rudenko has been able to construct his giant RepRap with input and feedback from the RepRap community, but the funding and actual construction work has all been his own. The enormous 3D printer is driven by the same Arduino Mega 2560 board and software as some other 3D printer kits, but with larger motors, purchased from the Mass Mind. It’s capable of extruding layers that are 20mm wide and 5mm tall. The contractor uses a concrete and sand mixture that, while it doesn’t dry instantaneously, solidifies sufficiently for the printing process to work, without necessitating the trowel and specially designed, quick-drying concrete that Khoshnevis’s Contour Crafting group uses at USC.

Rudenko seems to be pretty familiar with the work of the USC professor, intentionally differentiating himself:

I’m going in a slightly different direction than Behrokh Khoshnevis. I’m building a portable machine that could be used by regular contractors, which I currently see as being priced at about the cost of a car. Behrokh Khoshnevis’s printer is heavier and most likely priced much higher, which is why it looks like a good fit for large-scale companies, while mine will be well-suited for regular constructors/construction.

Differently than Behrokh Khoshnevis’s method, I’m creating a natural, free-layering of fine concrete. My goal is to have a nice-looking, natural texture, without a need for any additional finish. 25mm (1 inch) width x 10mm height is my standard dimension, which makes for easy calculations. But within reason, I am able to pretty much print layers of any dimension.

To keep the cost of materials low, I’m using a regular cement mix with additives. It is possible to use special quick-setting concrete to speed up the process, but it will affect the cost, and I don’t see much reason to build a house extremely fast at the expense of higher cost and lower quality.

Despite occasional issues with the viscosity of the material, Rudenko has made fairly significant progress in his work fabricating partial, reinforced walls. The wall in the video below is being printed in winter, with ambient temperatures slightly above 0°C (or 32°F), with Rudenko saying that it can withstand real world conditions.

The eventual plan is to 3D print a two-story home 10m x 15m in size and, unlike the recent homes printed in China, Rudenko will include plumbing, electricity and insulation in the construction process. His main concern, however, is “finding a lot for the experimental printing of larger structures like the two-story house” in Minnesota. He may even include some of his experiments as decorative elements in the final 3D printed structure. Until he begins construction on the house this summer, Rudenko will gradually expand the size of his experiments.

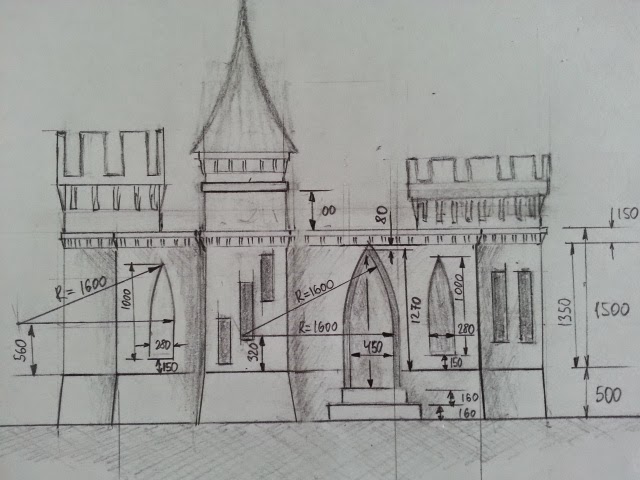

At the moment, he’s in the process of printing a playhouse to test the material and structural properties of his printing process. He says, “I’ve done a lot of experimenting on small structures; now I’m printing medium-sized structures, including the 3 x 5m castle. I’m choosing to print a castle form because it allows me to include a variety of different shapes and elements, including arches, etc, in addition to the fact that a medium-sized structure is the only size I can legally print in my backyard…The castle will take about a week for the setup, printing, and making of the video.”

Rudenko adds that, “I’m also thinking of inviting architectural/engineering students to attend the printing sessions. I’m creating an international community of people involved with this work who could interact, discuss, and share concepts to further this technology.”

The reasons for pursuing this epic endeavour aren’t merely for fun or media attention, which appear to be happy side effects, but to improve the field of construction and produce eco-friendly homes. Ideally, 3D home printers would prevent construction workers from being exposed to dangerous workplace hazards, like dust. Also unlike Khoshnevis’s, plans, building components like steel reinforcement will be installed manually, rather than robotically, making the process much more feasible. He explains, “For the sake of allowing people in construction to keep their jobs, yes, I wanted part of the work to be manual for the time-being. This also helps to not overburden the printer at the expense of efficiency. During the process of printing, I’m leaving channels to fish electrical wires and plumbing pipes through, and special channels for heating and air conditioning. Insulation is a major point of this project, and I will explain it in more detail on my website.” If made commonplace, 3D construction could reduce the amount of labour necessary to fabricate buildings, with Rudenko believing that only a computer operator, to run the printer, and a materials operator, to manage the cement and place reinforcement rods throughout the structure, would be required. And, as you might guess, 3D construction also greatly opens up architectural design opportunities.

After completing the two-story house, Rudenko hopes to build an energy efficient home that uses computer software to significantly limit the need for heating and air-conditioning, saying, “I plan to print a contemporarily-designed energy-saving house heavily relying on thermal mass energy storage principles, which will considerably reduce the continuous need for heating and air conditioning. I have developed a concept that incorporates forgotten energy-saving technologies controlled through a computer.”

The inventor is also in the process of upgrading his equipment to be able to 3D print on hills and in mountainous areas, where other forms of construction are more difficult. He says that this next generation of printer “is built on entirely new principles, and will hopefully lead to the development of new architectural designs/ideas.” Not only that, but he’s been experimenting with powering his concrete printer with solar panels and car batteries, meaning that the house printing process can be done off the grid. Rudenko says, “Soon I will be able to print a house in the middle of the wilderness without electricity sources, needing just cement + water + sand + good sunny weather.” The implications for remote communities could be profound.

Rudenko may eventually sell his construction machinery, but first he needs to prove that it will work. At this point, though, he’s confident that it will, concluding, “I’ve achieved good results, and I am moving forward with the 3D House Printer.”