About the amazing possibilities that 3D printing will offer space exploration, we have written everything and more. Paragon Space Development’s CEO Jayne Pointer told us how it will be key in long term space missions, Space X has publicized its extensive use of the technology, and NASA has just announced a whole bunch of 3D printable models, and even a new technology for 3D printing with multiple metals at the same time. This, however, is all just the beginning and one NASA engineer, Jason Budinoff from the Goddard Space Flight Center in Maryland, has announced not one but four very interesting space observation projects involving 3D printing that may change the way we look at space, literally.

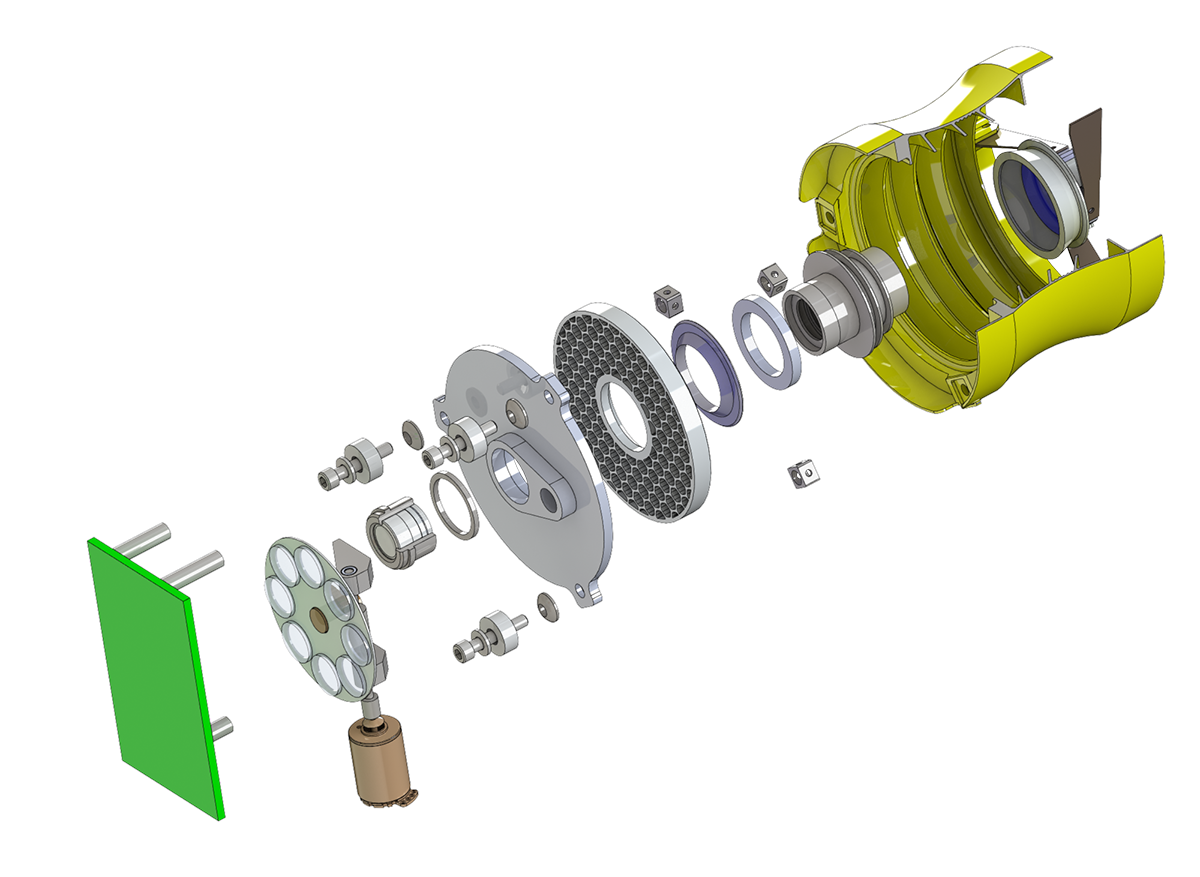

The first of these projects is a 50 mm working 3D printed Space Camera that will be almost entirely 3D printed as a single piece. Funded by the Goddard Internal Research and Development (IRAD) program, Budinoff’s camera will have its outer tube, baffles (the systems to reduce stray light) and optical mounts 3D printed as a single structure. The test project also involves using 3D printing to build and assemble a 350 mm dual channel telescope, whose size is more representative of a real space telescope.

“This is a pathfinder,” Budinoff said. “When we build telescopes for science instruments, it usually involves hundreds of pieces. These components are complex and very expensive to build. But with 3D printing, we can reduce the overall number of parts and make them with nearly arbitrary geometries. We’re not limited by traditional mill- and lathe-fabrication operations.”

The advantages of using 3D printing in this type of unique instrument are evident in terms of time and cost, but also in relation to the fact that certain complex elements simply cannot be manufactured by traditional methods, without assembling something like ten times the number of parts. When complete, the 3D printed camera will have taken just three months to build, at a fraction of the price. “I basically want to show that additive-machined instruments can fly,” Budinoff said. “We will have mitigated the risk, and when future program managers ask, ‘Can we use this technology?’ we can say, ‘Yes, we already have qualified it.’”

The only parts that will not be 3D printed in the camera will be the mirrors and lenses, but Budinoff has something 3D printed in store for these mirrors, as well. It relates to aluminum, a material that metal 3D printing users have recently begun to fully exploit. It is a highly porous material, which has always made it more difficult to use in additive manufacturing – especially to build a polished mirror – but Budinoff has developed a pressure chamber system that will exert a 15.000 psi pressure on a 3D printed, non-polished, aluminum mirror. Through this process, called hot isostatic pressing, surface porosity can be effectively reduced, yielding a mirror-quality, polished part.

The use of metal mirrors is particularly fit for infrared-sensing instruments, which operate at extremely cold temperatures for a more precise collection of infra-red signals. If all components in such a telescope could be 3D printed as a single structure – mirrors included – it would reduce the number of interfaces, thus increasing the instrument’s stability and durability (which is always good when maintenance has to be performed several thousand kilometers above the surface of the Earth).

Budinoff is also experimenting with a new metal alloy which is being prepared for 3D printing: Invar. A nickel-iron alloy with a uniquely low coefficient for thermal expansion, Invar was invented in 1896 by Swiss scientist Charles Edouard Guillaume (for which he receive the Noble Prize). “It is ideal for building very stable, lightweight skeletons that support telescopes and other instruments”, says Budinoff, who believes these experiments will benefit anyone who will build optical instruments.

For sure, Budinoff’s research will advance the work of those outside of NASA. After all, the agency has already allowed us to look at space observation from an entirely new, and more accessible, angle.