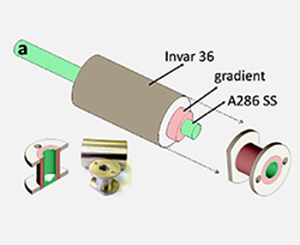

If you love the acronyms for 3D printing technologies, you might enjoy this new one: RDAM, which is short for Radiant Deposition Additive Manufacturing. And, if it does what NASA’s Jet Propulsion Lab (JPL) suggests it can do, it will dramatically change the face of metal 3D printing by introducing the possibility to laser melt three dimensional components formed with gradient metals alloys. That is, single components in which different portions are made up of different metal materials.

“We’re taking a standard 3D printing process and combining the ability to change the metal powder that the part is being built with on the fly,” said Douglas Hofmann, a researcher in material science and metallurgy at JPL, and visiting associate at Caltech. “You will constantly be able to change the composition of the material.”

With traditional manufacturing techniques, similar results could be achieved by welding different metal parts together. The weld itself, however, would result in structural weakness, not present with JPL’s RDAM 3D printing method.

Although applications of this technology will one day find their way into more “down-to-earth” applications in the automotive and commercial aerospace industries, this will likely not happen anytime soon. Currently, most companies operating in these fields have not even begun to scrape the surface of the possibilities offered by 3D printing with individual metals, let alone more than one metal simultaneously. Nevertheless, it will happen: we will 3D print in multiple metal alloys and we will conquer space.