Sadly, it doesn’t seem that anyone is listening. The project was launched back on July 21st, but, unfortunately, no one has currently pledged towards the modest $12,000 goal, at the time of this writing. To some, the Kickstarter production may be a bit rough around the edges, but they have some solid numbers and some very compelling reasons to support backing them.

The owners of HSM Furniture Matt Davis and Kevin Belton are already successful furniture sellers, but they find themselves hampered by the mass produced nature of modern furniture. When everything is produced overseas in massive quantities, consumers are going to be less likely to find the right piece of furniture that fits into their lives and homes. The only other option is to have something custom created for you; however, due to the cost, that is, as always, a luxury reserved only for the very wealthy.

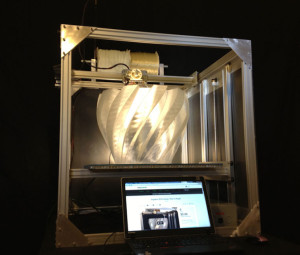

Davis and Belton are asking for an extremely reasonable $12,000, mainly because they already have a successful business, workforce and a working infrastructure in place. They really only need the investment money for hardware and supplies. If the project is funded they plan to purchase a large re:3DGigaBot 3D printer, wood filament and some basic 3D design consultation. This honestly seems like a simple, yet viable business idea with realistic and attainable goals.

The lack of movement on the Kickstarter has me curious about why it didn’t catch on. Yes, Kickstarter campaigns are usually hit or miss, and, so often, great ideas get ignored because of poor timing, unclear and unprofessional looking presentations or a lack of compelling rewards for supporting the project.

And, while all of those are possibilities, I wonder if part of it may be that 3D printing still has an image problem. Perhaps, there is a fear that 3D printed furniture will not be as sturdy or as well-made as traditionally produced furniture. Or, perhaps, people still think 3D printing is for toys and plastic trinkets and don’t know that the technology has advanced to the point where it has clear real world manufacturing applications. Or, perhaps, this is simply a case of the internet – fickle as it is – not being interested at this time.

Whatever the reason, I think Davis and Belton’s Kickstarter is worth looking a bit closer into, even if, at this point, just to open up a discussion of the damage that massive unchecked globalisation and over-consumerism is doing to our artisan communities.