Consumers may be familiar with iRobot, the corporation responsible for a series of home cleaning machines donning cute names: Roomba, Scooba, Verro and Looj. War buffs are more aware of their line of military bots and prototypes named by an eight-year-old who loves Saturday morning cartoons: Warrior, R-Gator, Negotiator, Transphibian and Chembot[1]. The 3D printing world, however, knows iRobot by its latest patent: a fully-autonomous 3D printing station.

In the process of fused deposition modeling, in which layers of material are extruded and joined together with a bonding material, there are inherent inefficiencies. If an object that’s being printed is too large or has overhanging features, support structures and scaffolding must be manually placed onto the printing platform. This prevents heavy printed pieces from dripping or falling over and disturbing the printing process. Additionally, projects are often printed in parts and later manually assembled. iRobot’s patent of a “Robotic Fabricator” describes a machine, outfitted with arms and sensors, that seeks to eliminate the problem of human intervention and inefficiency altogether.

The patent outlines the process in words that could have only been written by the robot itself:

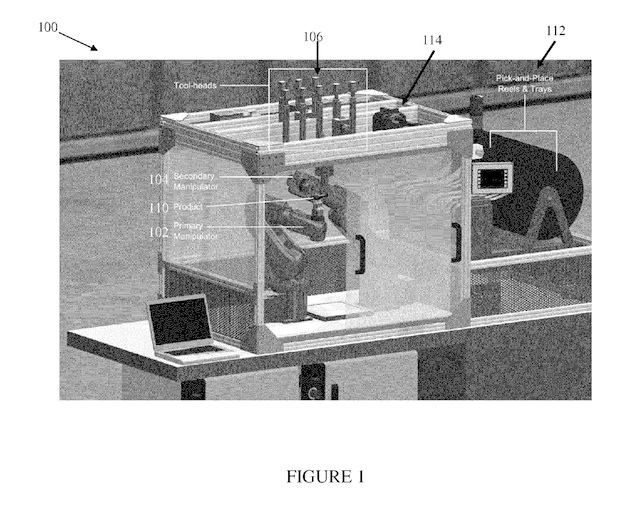

The systems and methods described herein include a fabrication machine/method that fuses additive and subtractive manufacturing with in-situ component placement to provide completely autonomous all-in-one product manufacturing. Product fabrication is centered around a six-axis industrial robotic manipulator (primary manipulator) that handles the product from seed component to mature product. The primary manipulator positions the product for manufacturing operations such as additive and subtractive manufacturing (3D printing, milling and drilling). A secondary manipulator handles component pick-and-place and secondary manufacturing operations such as wire placement and hardware testing. According to one feature, all-in-one product manufacturing increases the ability to produce prototypes or small production runs of devices, since no human intervention is used, product design is simpler and production is more efficient.

The possible iterations of the machine put forth in the document often include camera and laser sensors that can determine at what stage a product is in during the manufacturing process. It can then, hypothetically, rotate or support the object, without the need for manual interference, and clear away any scaffolding through the use of its subtractive/milling functions.

According to the patent, this complex, all-in-one production station could be used in the simple creation of new items; to modify existing items; or to repair broken items by scanning them, comparing them to their original manufacturer’s specifications and replacing broken parts. And, though the US Defense Budget may be cut from $645 billion to a mere $613 billion[2], which means that the military may be demanding fewer robotic scouting units, the patent explains one possible use that the machine may have for defense purposes:

The fabrication machine may be used by the military in the field. In one example, a soldier in the field may use the fabrication machine to modify a surveillance robot. For example, if the surveillance robot is unable to climb over obstacles in the field, the soldier may use the fabrication machine to create and fabricate a new design. In another example, an offsite military personnel may redesign the surveillance robot and transmit the new design to the soldier in the field. The soldier could use the fabrication machine to easily fabricate a new surveillance machine with minimal product fabrication knowledge. In general, the fabrication machine improves manufacturing capabilities and innovation by increasing access to 3D printing while also reducing costs and required production skills.

I can also picture this station, after it’s perfected on the battlefield, to make its way to places like Staples, which has already announced that it will be introducing Mcor 3D printers in its European stores, where customers will be able to have their printed goods repaired or upgraded.

iRobot’s move into 3D printing is one sign of the additive manufacturing industry’s continued success and, as Michael Robinson of Money Morning suggests, the company offers another option for potential investors who are sure about the future returns of a 3D printing investment, but are a bit skeptical of industry leaders, 3D Systems and Stratasys, which many analysts have claimed to have overvalued stocks. It’s possible that 3D Systems and Stratasys could be overtaken by other players new to the stock market, like ExOne, which had its IPO on February 7th.

Whether or not the stock prices of DDD and SSYS do drop, I think that new entries into the market can only mean that there will be even more 3D printing in my life. And, anyway, I am no stock analyst. What I do know is that, if I didn’t have to save up for my wedding in September, I’d buy some Organovo stock. That stuff is trading at something like $4.50 a pop and, if I had invested in it back in August, I would have doubled my money and went out and bought me a racehorse.

Source: Money Morning, Google Patent

[1] Chembot is a DARPA-funded, publicly subsidized, robot that is equal parts terrifying and cool. Like T-1000 in Terminator 2, Chembot’s structure is flexible, moldable, so that it can squeeze through tight holes and, someday, impersonate your mother.

[2]Compare this figure to the $69 billion budget proposed by the US Department of Education.