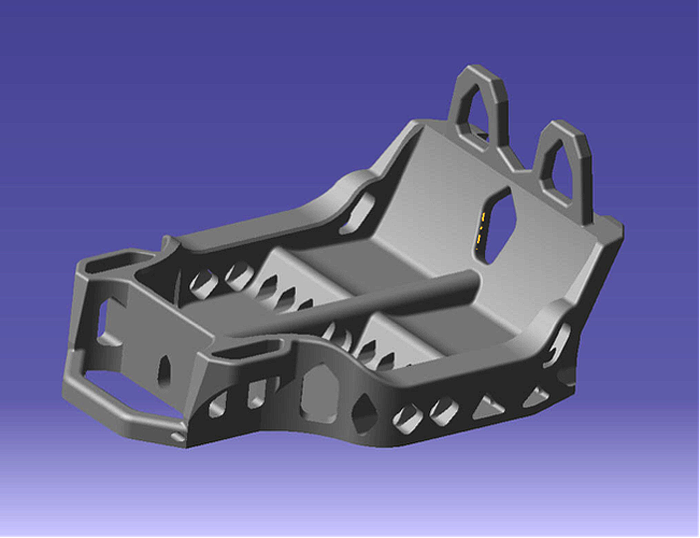

Local Motors and Oak Ridge National Laboratory have begun trials on their 3D printed car today and, while not entirely successful, they’ve produced some interesting results. The partners first intend to 3D print the chassis (or tub) of their auto, which will be attached to a powertrain and driven around as a means of testing the strength of their 3D printed parts. The ultimate plan, though, is to fabricate the majority of the auto as a single piece. Here’s the print they were hoping to make today:

After feeding their ABS/carbon fiber composite into the hopper of ORNL’s giant RepRap, the machine purged some material until it had reached optimal printing conditions. Local Motors posted a picture of the strands of material pumped out of the nozzle and the size of the ABS/carbon fiber tubes is pretty impressive. ORNL is also working on some new extruder nozzles, to add finesse to the project, so expect more variety than what you see below in the future.

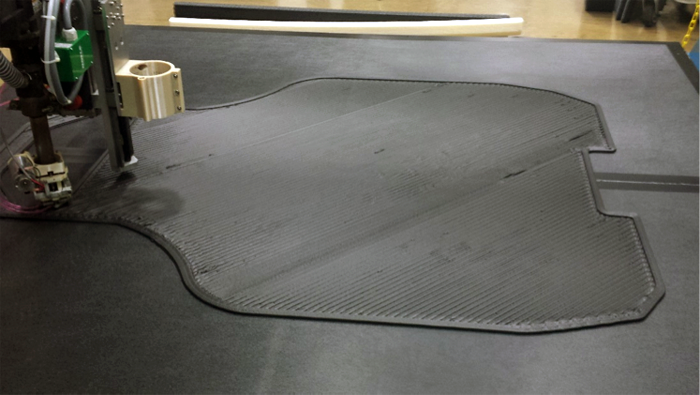

It took about an hour to lay down the first layer of the print. They had hoped to print the first two layers as 100% solid, followed by two layers at 25% infill, proceeded by another two layers of 100% infill, before moving onto the more complex features of the chassis.

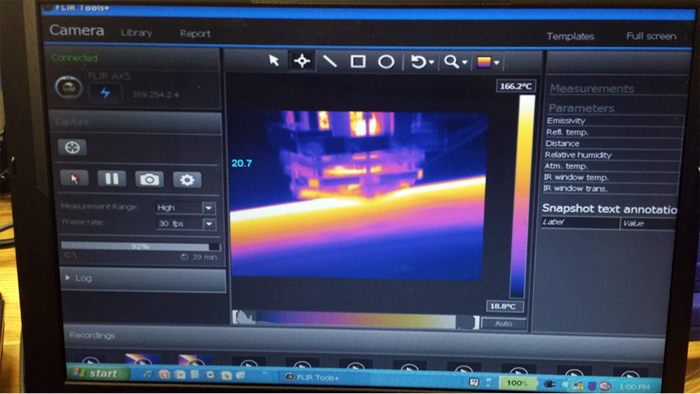

During the entire process, ORNL had thermal cameras monitoring the temperature of the print at various points, something my RepRap, unfortunately, lacks.

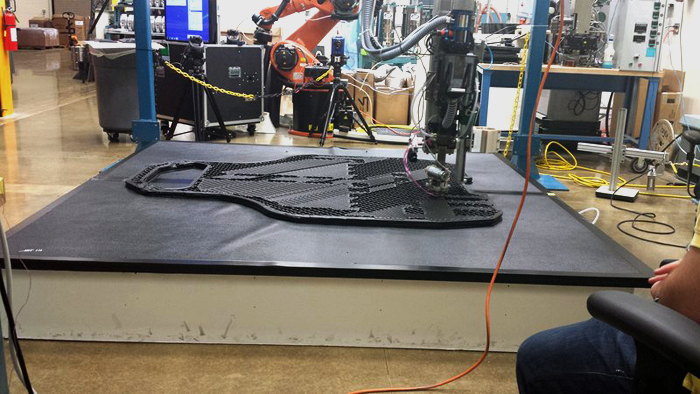

After about nine layers of printing, however, the print ran into a couple of problems, according to the Local Motors blog: “Mainly from the contraction of the part as it cooled due to the large nature of the piece, and also the software used to generate the g-code was struggling with the translation.” What they had made so far, is still very exciting.

The pictures reveal that the process is definitely feasible. As with all new 3D printers, even giant car printers developed by nationally funded laboratories, there are always snags when you first get the thing going. So, it should be of no surprise that ORNL ran into a bit of trouble when running their first test print for Local Motors’ 3D printed car. But, as any 3D printer user knows, such obstacles are only temporary and, once you can a handle on the machine, you’re in store for some amazing prints.

Source: Local Motors