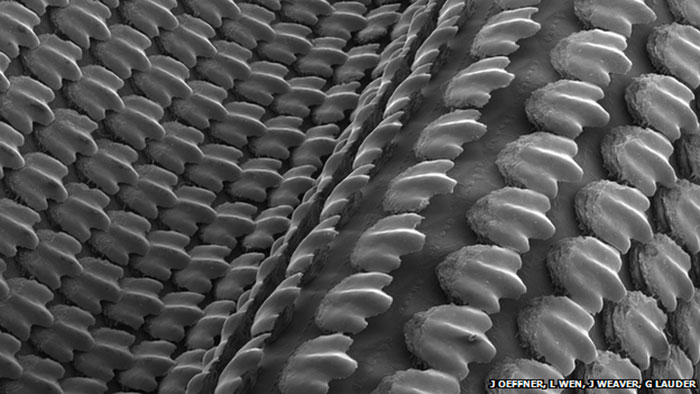

Shark skin is an amazing feat of engineering in nature. Tiny teeth or ‘denticles’ line the surface of the skin, creating turbulence that reduces drag. With this in mind, engineers have tried to mimic the shark skin when designing everything from swim suits to racing cars. Recreating the denticles has always been a bit of a challenge. Now, scientists have used a 3D printed model of shark skin to replicate how the tooth-like scales aid these beautiful creatures to cruise efficiently.

The functional properties of shark skin have been of considerable interest to both biologists and engineers for some time, but because of their complexity, no study to date had successfully fabricated a shark skin that allows detailed study of its function. Until now.

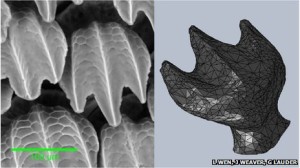

This flexible 3D printed shark skin model was then tested in water using a robotic device to create movement that allowed the team of scientists to either hold the models in a stationary position or move them dynamically at swimming speed. The 3D printed shark skin showed increased swimming speed with reduced energy consumption under certain motion conditions compared with a smooth control model without denticles.

Prof Lauder told the BBC that the particular shape of the denticles also posed difficulties: “Because they’re overhung, the 3D printers have to print a supporting material, which you then have to remove. It took a while to work out all the tricks. You have a rigid scale structure embedded into a flexible membrane, that can then swim.”Transferring this type of design to a textile might take decades, Prof Lauder said. “But if you could do it, you would see a dramatic effect on swimming performance… It pays us to understand how the natural world works.”