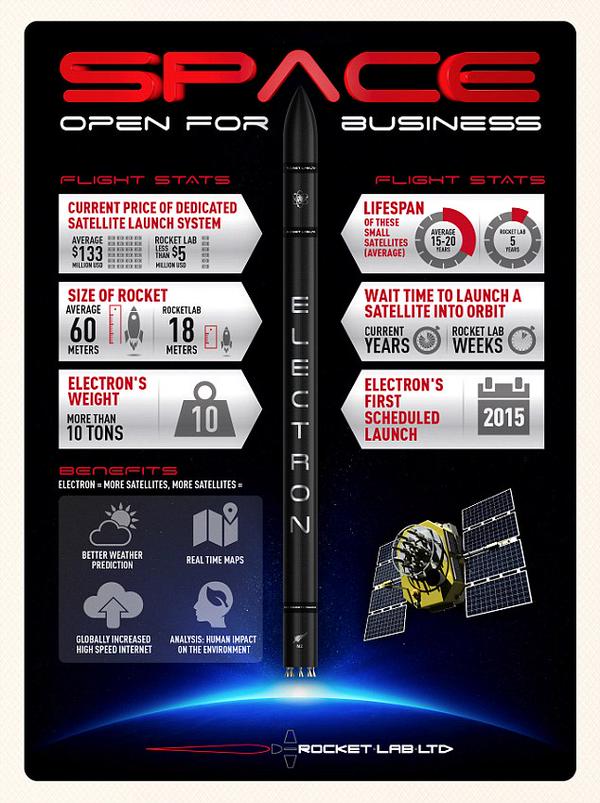

Launching satellites into space is a privilege reserved for governments and multi-million dollar companies. Typically companies spend between ten to fifty million dollars per launch. Now, with the help of 3D printing, New Zealand company Rocket Lab can launch a small satellite into orbit for just $4.9 million.

The key for it all, according to Beck ,is the 3D printed engine that can be built in just three days. The lower cost and quick production delivers on both cost and frequency, making it affordable for smaller companies to invest in satellites and opening up the increasingly competitive market.

The small satellite industry which include radio, broadband, street-mapping and television service providers are jumping at the chance to take advantage of Rocket Lab’s services. From universities to governments, already around 30 companies have signed up. Beck says that Lockheed Martin and Khosla Ventures are two of Rocket Lab’s leading investors.

Rocket Lab CEO Beck says, “Over the past couple of years, we’ve seen a tremendous amount of private capital go into small satellites, we’re witnessing the democratization of space. Space was really the domain of governments, and now it’s moving into the private commercial world.”

Rocket Lab is not the first in the space industry to turn to 3D printing. NASA has long been using and researching 3D printing for space operations, developing the first copper rocket engine part back in April. Chris Protz, a NASA propulsion engineer said at the time, “Our goal is to build rocket engine parts up to 10 times faster and reduce cost by more than 50 percent. We are developing a repeatable process that industry can adopt to manufacture engine parts with advanced designs. The ultimate goal is to make building rocket engines more affordable for everyone.”

But NASA isn’t the only big player in the space industry getting involved with additive manufacturing. Last July, billionaire Elon Musk’s SpaceX launched a rocket with a 3D printed valve body in one of its engines. The American aerospace firm released a statement last year that said, “Compared with a traditionally cast part, a printed valve body has superior strength, ductility, and fracture resistance, with a lower variability in materials properties. The valve body was printed in less than two days, compared with a typical castings cycle measured in months. This will ultimately make the spacecraft fully and rapidly reusable – able to be refueled and reflown multiple times, drastically lowering the cost of space travel.”

Anybody want to launch a satellite?