Only a small handful of copper rocket parts have been produced using additive manufacturing, but NASA has managed to 3D print the first full-scale copper component for a rocket engine. This is big news for future Mars missions, as well as taxpayers who have previously footed the bill for traditional manufacturing costs.

Steve Jurczyk, associate administrator for the Space Technology Mission Directorate at NASA Headquarters in Washington says of the accomplishment, “Building the first full-scale, copper rocket part with additive manufacturing is a milestone for aerospace 3-D printing. Additive manufacturing is one of many technologies we are embracing to help us continue our journey to Mars and even sustain explorers living on the Red Planet.”

There are a lot of parts required to build a rocket engine, and all of those parts need to be able to withstand extreme heat and extreme cold. 3D printing has the potential to reduce the cost and time of making parts for rocket engines like the copper liner found in a rocket’s combustion chamber. In this chamber ultra-cold propellants are mixed together and heated to the max to allow for the combustion that thrust the rocket into space.

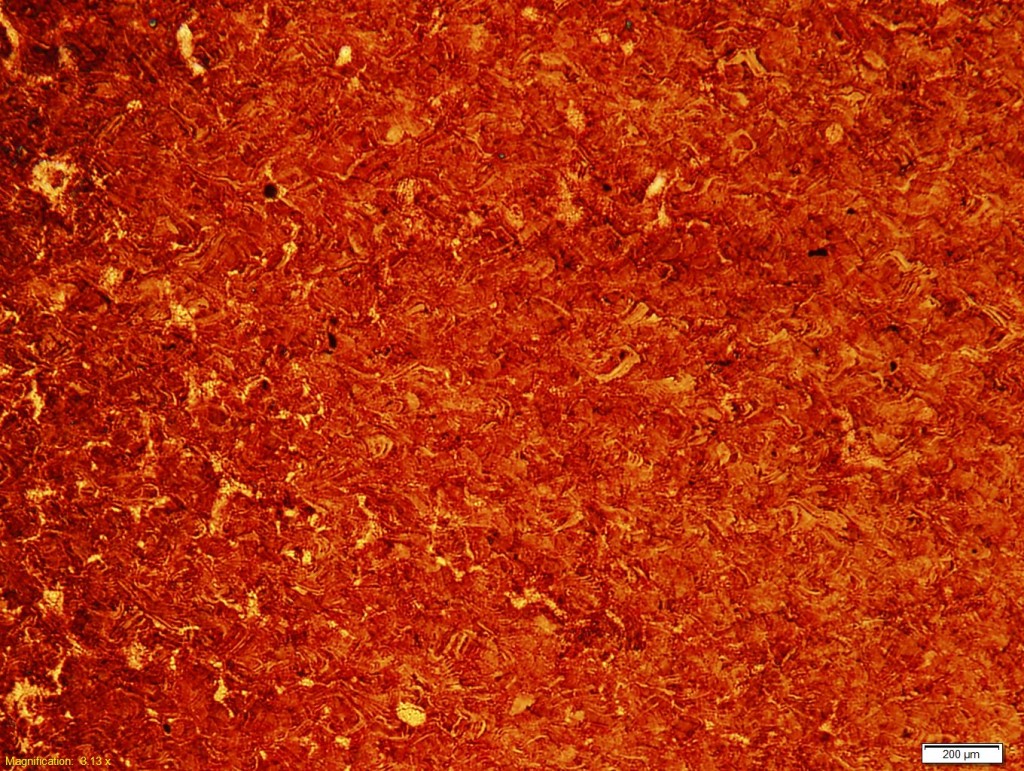

Chris Singer, director of the Engineering Directorate at NASA’s Marshall Space Flight Center where the copper liner was manufactured elaborates, “On the inside of the paper-edge-thin copper liner wall, temperatures soar to over 5,000 degrees Fahrenheit, and we have to keep it from melting by recirculating gases cooled to less than 100 degrees above absolute zero on the other side of the wall. To circulate the gas, the combustion chamber liner has more than 200 intricate channels built between the inner and outer liner wall. Making these tiny passages with complex internal geometries challenged our additive manufacturing team.”

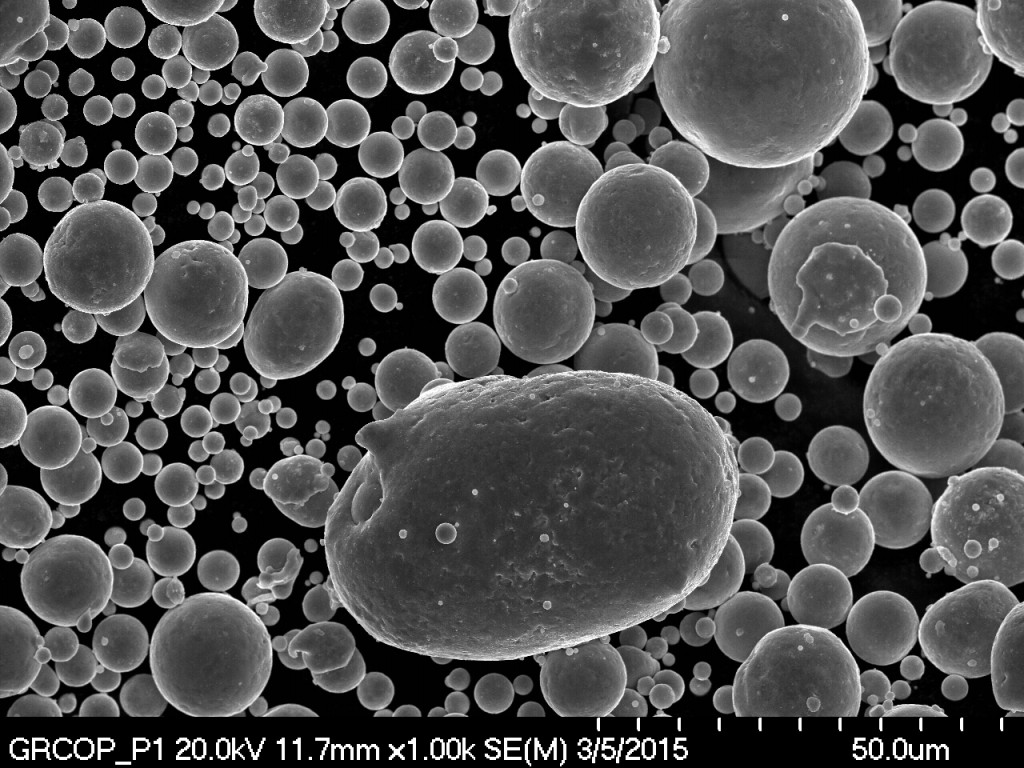

The copper liner was created in Marshall Space Flight Center’s Materials and Processing Laboratory in only 10 days and 8 hours. First, the team had to build several other test parts to characterize and create a new process for 3D printing with copper. The lab team then used a selective laser melting machine to fuse 8,255 layers of copper powder.

Zach Jones, the materials engineer who headed up the team at Marshall explains, “Copper is extremely good at conducting heat, that’s why copper is an ideal material for lining an engine combustion chamber and for other parts as well, but this property makes the additive manufacturing of copper challenging because the laser has difficulty continuously melting the copper powder.”

Materials scientists at NASA’s Glenn Research Center in Cleveland, Ohio created the GRCo-84 copper alloy material used to manufacture the part with the intention of developing a database of the mechanical properties of materials in order to help future 3D printed rocket engine designers. Data on the project will be made available to American Manufacturers in NASA’s Materials and Processing Information System (MAPTIS) in hopes that the US will take the manufacturing lead using this new technology.

3D printing is just the beginning, says Chris Protz, the Marshall propulsion engineer leading the project. “Our goal is to build rocket engine parts up to 10 times faster and reduce cost by more than 50 percent. We are not trying to just make and test one part. We are developing a repeatable process that industry can adopt to manufacture engine parts with advanced designs. The ultimate goal is to make building rocket engines more affordable for everyone.”

The impetus to use additive manufacturing to develop space technology is in alliance with NASA’s Game Changing Development Program, which funds the development of technologies that will revolutionize NASA’s journey to Mars and all future space endeavors. For now, the 3D printed copper liner will travel to NASA’s Langley Research Center where a nickel super-alloy structural jacket will be put on the outside of the copper liner. After that, the part will travel back to Marshall to be hot-fire tested before the part makes it into an actual rocket engine.