Sometimes I just get overexcited about 3D printing news but that happens because, at this early stage of the industry, every small innovation represents something huge that may (or may not) happen in the future. Such is the case for Makerplate.

It is a specialty plate made by a small company based in Wisconsin. They are now on their first run, and the plate is currently only compatible with the MakerBot Replicator 2, but in a way they represent a big step for the consumer 3D printing industry. A step in which innovation is no longer disruptive of what came before it but builds on what is there now.

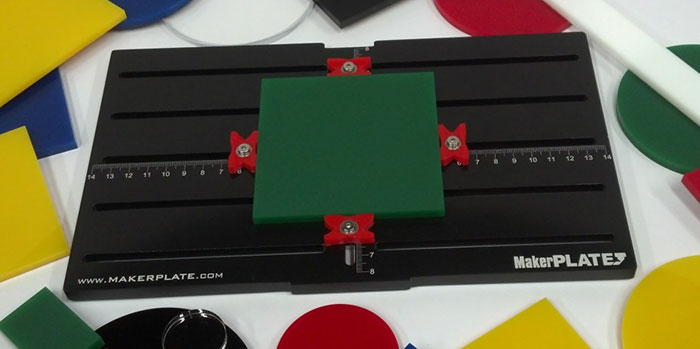

The Makerplate retails at $89 and answers a very specific need of FFF 3D printer adopters, namely it allows the use of preset acrylic plates of different shapes onto which to build any object. This way the actual print job is more colourful and requires less time and filament.

The team behind Makerplate had set out to print on objects other than the traditional build plate, with the intent of creating a permanent two-piece part consisting of a base and a printed part on top. They found it was very (very) difficult to keep the base held in place and lined up and decided to design a reliable build plate that could hold a wide range of objects and be adaptable to most desktop 3D printers.

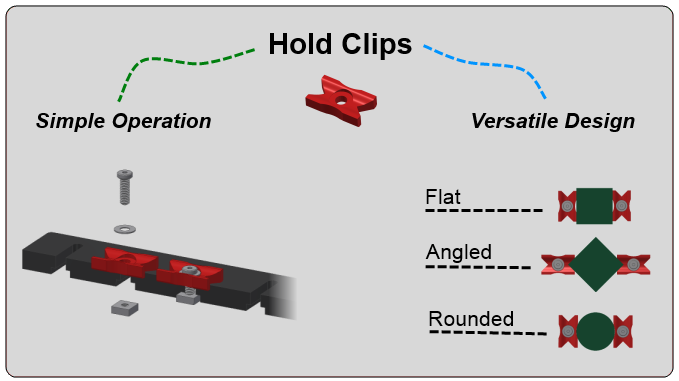

The Makerplate achieves this by using four red hold clips that get screwed in to secure the acrylic plate (to be purchased separately). According to the direction in which they are set they can be used to lock in flat, angled or curved borders. After removing the standard build plate, the Makerplate snaps right in, then all you need to do is install a very important levelling piece to ensure the nozzle does not run into the part you are printing on.

Just a simple extra or the beginning of a consumer 3D printing after-market customization boom?