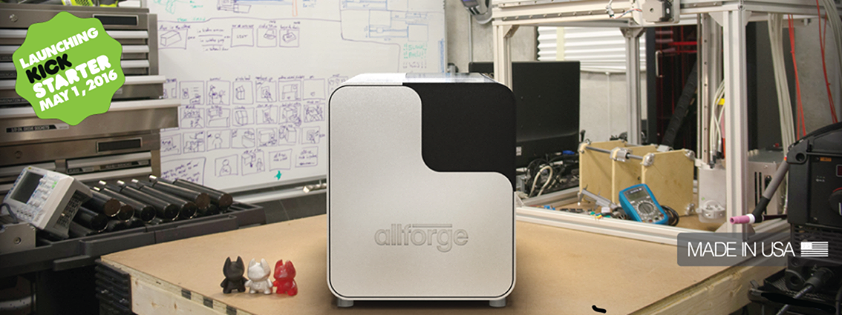

Now that we have seen the possibilities of desktop manufacturing tools like 3D printers, CNC routers, and laser cutters, it’s time to kick the digital fabrication revolution into high gear. That’s why new startups are coming out of the woodwork with completely new methods for DIY manufacturing. In January, we covered a firm called Mayku, which has planned the release of a number of desktop production tools, like the FormBox and the RotoBox. Now, a startup called Allforge, out of Jupiter, Florida, is preparing to launch a series of 3D molding machines, for rapid, desktop molding. From the sound of it, what they’re working on is pretty impressive and it will be hitting Kickstarter on May 1.

Initially, Allforge established its online community with coy marketing messages hinting at the product they intended to release, but, soon, members started asking so many questions that the firm had to spill the beans. Allforge has developed what they call “3D molding machines”, capable of rapidly casting objects out of molds, 3D printed or made otherwise. Allforge CEO Shane Allen writes, “You will either 3D print these molds yourself out of plastic, CNC them out of metal/plastic on your home mill, or we have teamed up with 3D Hubs to allow you to go on our website to order a 3D printed mold from a 3D printer near you – as fast as same day delivery! You then simply load the mold, select quantity on our app, and you are off making your parts – completely hands off and automated!”

So far, the firm has three different models, depending on the application: the Allforge Boss, Startup, and Sweet. The names give you a bit of a hint as to their capabilities. The Allforge Sweet can heat material high enough to cast objects made from dessert materials. The Startup gets a bit hotter, burning hot enough to melt plastic and sweets. And the Boss is their most heavy duty machine, with three separate material channels for molding in plastics, metals, and sweets.

While the Boss can’t quite reach the 1500°F temperatures necessary to melt brass and bronze, it can handle metals that melt below 650°F and Allen says that advanced users might be able to push it up to “aluminum melting temps around the 1200F mark.” This means, he adds, metals like “bismuth, lead, cadmium, indium, tin, pewter. We don’t recommend lead and cadmium though due to their inherant potential toxicity. More advanced users will have the ability to use aluminum, magnesium, zinc and more!” For use with the Boss, Allforge has worked with metallurgists to develop a “non-toxic” metal for use with casting ABS parts.

The Allforge Startup is for the Maker that may not want to mess with metals. Using plastic pellets (or dessert materials), the Startup allows users to cast ABS, PLA, and other plastics using their own molds, resulting in low-cost production that is much more rapid than 3D printing technologies. It’s likely that it will even be able to use shredded plastic bottles, as well. Finally, the Allforge Sweet is for low-temperature materials, like chocolate, taffy, silicone, and even soap and wax. All of the machines are meant to be upgradeable so that, once you’ve become an expert at custom caramels, you can move up to plastic and metal.

In terms of specs, the cast parts have about 90%+ the resolution of the mold. The machine has a production volume of 100cc+ (3.4oz) for plastics, 250cc+ (8.5oz) for metals, and 300cc+ (10oz) for low-temperature materials. Molds can be 200x200x50mm in size, but Allen suggests that advanced users will be able to get even more out of the system around 200x200x200mm. Creating parts only takes a few seconds, but the process of cooling between manufacturing parts adds a bit of time, but only really a few minutes. Allen gives these estimates for making a part of 77 x 60 x 42mm (3.03 x 2.36 x 1.65in): “Metal Making Time: 5min 32seconds (≈12/hour), Plastic Making Time: 5min 18seconds (≈12/hour), Hard Candy Making Time: 2min 8seconds (≈30/hour).”

The Allforge machines have cooling cycles between each part made, that is mainly the bulk of the time which you are waiting. The part creation itself only takes a few seconds each – the machine must wait for it to cool down to a certain temperature before it is allowed to release the part. But they say that this entire process is automated! You just tell the device, through an iOS or Android app, just how many copies you want to make and it does the rest.

Allforge will be supplying a mold file, which includes a preset sprue, for introducing material into the cavity, adjustable vents, and extrusion pinholes for removing the object. While 3D printing a custom mold is part of the idea here, the company will also be supplying a library of pre-made molds to be ordered through the site for home printing or to be made and delivered via a partnership with 3D Hubs.

Of course, this molding process does not have the same benefits as 3D printing, in terms of part complexity, but it does bring small batch production to the desktop. And Allen suggests that some internal voids are possible using three-part molds.

Of course, crowdfunding backers have to always wonder if a Kickstarter like this will be able to fulfill its promises. The team has experience establishing the Allforge parent company Modti Inc. This Finnish company has developed a technology capable of producing what it calls Shape Programmable Components (SPC) and Shape Programmable Surfaces (SPS), creating 3D shapes from 2D surfaces. Their flagship product is Segment, an electrically driven, flexible, thin actuator bending mechanism.

If the company is capable of producing flexible electronics, then a low-cost molding device should be no trouble. Now, we just have to wait for May 1 and the desktop manufacturing revolution to really begin.