With former CEO Avi Reichental, 3D Systems began to place noticeable resources into the company’s consumer division – some say, at the expense of their key industrial technologies. Now that he has stepped down and a new CEO has stepped up, the inventor of 3D printing has begun refocusing its energy on industrial 3D printing, releasing its first new SLA process in some time. The all-new Figure 4 3D printer is no ordinary rapid prototyping system. Due to its use of an industrial robotic arm, the Figure 4 platform is engineered for mass production.

The system sees an industrial robotic arm act as the printer in stage one, pulling a print up from a vat of resin as it is cured layer by layer at rapid speeds. This is due to a specialty membrane used between the light source and the resin. Though the exact details of the membrane have not been disclosed, the concept itself is similar to that implemented by Carbon, which allows for high-speed 3D printing.

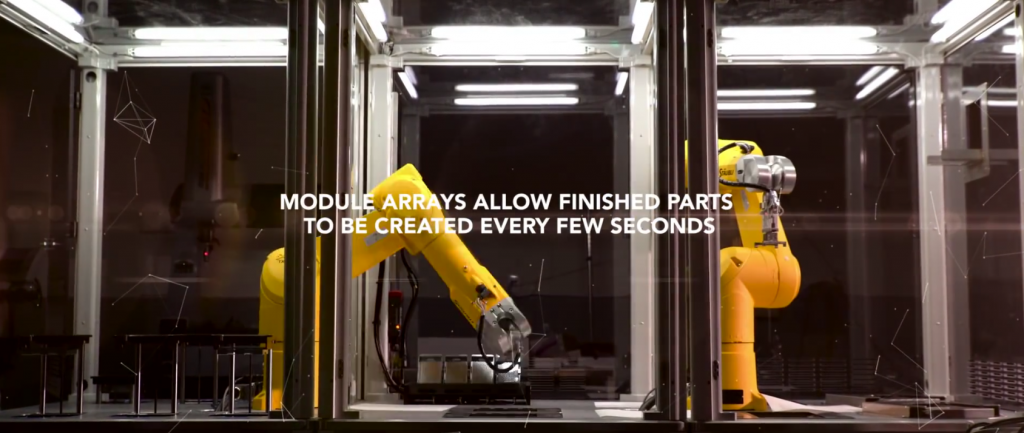

Upon printing, excess material is then recovered from the print, before the object is washed and cured further as a part of post-processing. Because the process is scalable, the possibility exists to create arrays of such systems to mass produce these SLA parts. 3D Systems has also engineered photopolymers for the process, which include hybrid materials for unique qualities of strength, wear resistance, temperature deflection, biocompatibility, and elastomeric qualities.

There are still a number of details left undisclosed about the Figure 4 platform, such as the type of membrane it uses, its commercial availability, and the type of light source used, but the system is an intriguing one. Hopefully, now that Reichental’s Cubify-style marketing tactics are out of the picture, what we see is what we get. If so, the Figure 4 could be the platform that puts 3D Systems back on the 3D printing map.