This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

John Hornick is an IP counselor and litigator at Finnegan, one of the world’s largest IP law firms. Hornick leads Finnegan’s 3D Printing Working Group and authored the book 3D Printing Will Rock the World.

Any opinions in this article are not those of his firm and are not legal advice.

3D Printing the Next 5 Years by John Hornick

I laid out my 10-year vision in my book, 3D Printing Will Rock the World. Here, I focus my crystal ball on the next five years.

Machines

The next half decade will see machine manufacturers combining 3D printing methods, as HP did with Multi Jet Fusion, which combines something like Binder Jetting with Material Jetting, Powder Bed Fusion, and possibly Directed Energy Deposition (DED). We will also see innovations in ASTM International’s 7 basic types of 3D printing technologies, such as Markforged’s process for making dense metal parts with Material Extrusion and Adamtec’s metal parts made with Vat Photopolymerization. We will also see innovations beyond the seven basic processes, such as Disney Research’s 3D copier and Carbon’s CLIP, and Boeing’s true 3D printing process, which builds in multiple axes, not just Z. The Disney and Carbon processes are like injection molding without the mold, making instantaneously whole parts. No layers. Boeing combines a levitated part, multiple build heads (could be Binder Jet, DED, Material Extrusion, or Material Jet, or all of the above), and apparently infinitely variable orientations to such heads. The next five years will also see increased integration of 3D printing with in-process controls (such as Sigma Labs’ PrintRite3D), robotics, and post-processing.

Design

In the next five years we will see powerful design software and design training that breaks the paradigms of Design for Manufacture, graduating a new breed of designers fully capable of making full use of the power of 3D printing. Designs will be increasingly organic, less linear. They will look more like they were grown than built, more like Mother Nature’s designs. Parts will be increasingly topologically optimized and biomimetic. Designers have already started to explore the tip of this iceberg. I show some great examples in my book.

Materials

Impossible Objects’ Bob Schwartz once said to me that 3D printing is purely an exercise in materials science. 3D printing has ushered in a Golden Age for materials scientists.

Just as 3D printing can reduce part count, as GE’s famous fuel nozzle reduced parts 18:1, materials scientists will develop materials that enable a product to be 3D printed from versatile or digital materials, substantially reducing material count as well.

Bioprinting

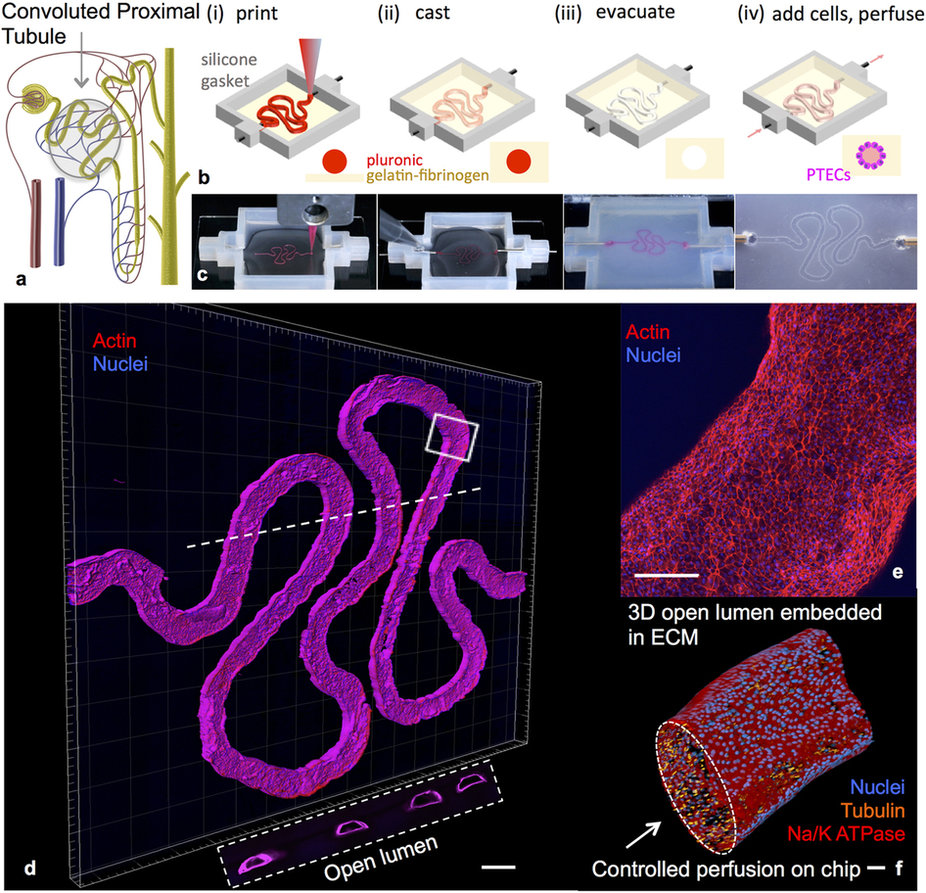

In early 2016, commentators were still saying that it would be a decade or more before anyone 3D printed the human heart, then Celprogen reported a functioning, 3D printed, miniaturized version in September, followed by a human pancreas in December 2016. Over the next five years, bioprinting will succeed at a dizzying pace, using machines like nScrypt’s bioprinter, which is the gold standard and will be used on the International Space Station.

But don’t expect to receive an FDA-approved replacement heart if you need one. By the time a replacement heart is perfected and wends its way through FDA approval, substitute hearts will be available (but probably not approved within 5 years). Hmmm.

Replacement heart or substitute heart. What’s the difference? Replacements attempt to replicate Mother Nature’s heart design. Ethical issues aside, substitutes will attempt to improve on it. Let’s face it, the human heart was not designed for the human lifestyle. Substitute hearts (and other organs) will combine the power of 3D printing and bioprinting, marrying organic materials and biological structures with inorganic materials and mechanical structures. Combining bioprinting and 3D printing will yield substitute bio-mechanical organs more suited to the human lifestyle and current longevity.

We will also start to see biomechanical substitute parts and products for machines other than the human body.

Intellectual Property

3D printing machine innovations will force incumbent 3D printing companies to travel down R&D paths they may not otherwise have trod, which will be necessary to compete, but will also generate patent wars absent a savior, such as a patent pool. A patent pool could free the industry to develop (radio developed under a patent pool that became known as RCA), largely unhindered by patent litigation. But the industry probably will not accept a pool, so patent wars are likely.

As I explain in detail in my book, as 3D printing democratizes, distributes, and regionalizes manufacturing, IP laws and other laws that regulate commerce will suffer the 5 Is (pronounced “eyes”). IP Infringement (or other Illegal activity) will increase. As it increases, infringement or other illegal activity will become increasingly difficult to Identify. If it cannot be identified, it will be Impractical or Impossible to enforce the relevant laws, at which point the laws become Irrelevant.

I call this 3D printing “away from control,” which means making virtually anything without anyone knowing about it or being able to control it. Of course there will always be 3D printing within control, so companies should and will continue to develop strong IP portfolios. Developing strategic portfolios (rather than the common approach of just “getting a patent”) will become increasingly important for obtaining financing, generating licensing streams, defending against third party IP, and excluding competitors. However, because of macro legal, economic, and policy trends that have already begun, IP rights will probably become weaker and narrower over time.

Crime

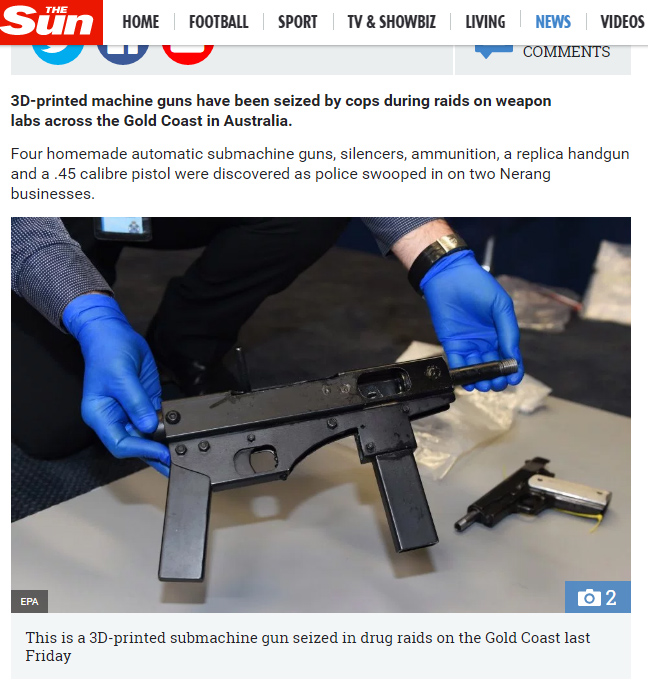

As the visionary counsel for ACID (Anti-Copying in Design), Nick Kounoupias, said to me, “criminals tend to be early adopters of technology.” Criminals and others are already 3D printing detectable and undetectable weapons and fake facades for bank machines. All of the strengths that make this technology a disruptor for manufacturing can also make it a powerful instrument for crime. The next five years will see the increased use of 3D printing for criminal activities, away from control.

Education and Policy

The next five years will see policy makers increasingly looking to 3D printing to return manufacturing to countries with high labor costs, which will result in increasingly regionalized and distributed manufacturing, such as Adidas’s Speedfactory, a network of automated 3D printing factories where “each consumer can locally get what they want, when they want it,” and the UK’s William Cook company, which saved 200 Sheffield jobs by investing in 3D printing for regional manufacturing.

The same policy makers and the private sector will continue to educate their populace on 3D printing, not just to teach them how to use the technology to improve their manufacturing bases, but also to teach STEAM education. This is already happening in schools all over the world, where 3D printing is being used to teach history, architecture, engineering, science, math, and art to students of all ages. As America Makes’ Ed Morris says, 3D printing education should be “for pre-K to gray.”

Crystal Ball Clear

My crystal ball says these things will happen or will be well along in five years. But the future is a long time. Even if I am off by 5 years, or ten, or more, 3D printing will rock the world.

This is a guest post in our series looking at the future of 3D Printing, if you’d like to participate in this series then contact us for more information. For more insights into the 3D printing industry, sign up to our newsletter and follow our active social media channels.

Don’t forget that you can vote now in the 1st annual 3D Printing Industry Awards.

More information about Finnegan is available here.

#futureof3Dprinting