Adidas is moving closer to a 3D printing shoe manufacturing revolution. As previously reported the sports shoe manufacturer used 3D printing to produce the Ultraboost Parley and 3D Runner releases in 2016. This year, Adidas are keen to up the tempo with their Speedfactory concept.

Industrial factories where 3D printing and robotics manufacture sneakers on-demand are at the core of the plan. Manufacturing will also become localized, eliminating costs associated with logistics and supply chains. Large-scale production at German Speedfactory in Ansbach is set for mid-2017, with Adidas expecting to create 500,000 shoes a year in the future. While in the U.S, Adidas has announced plans to create a Speedfactory in Atlanta in late-2017.

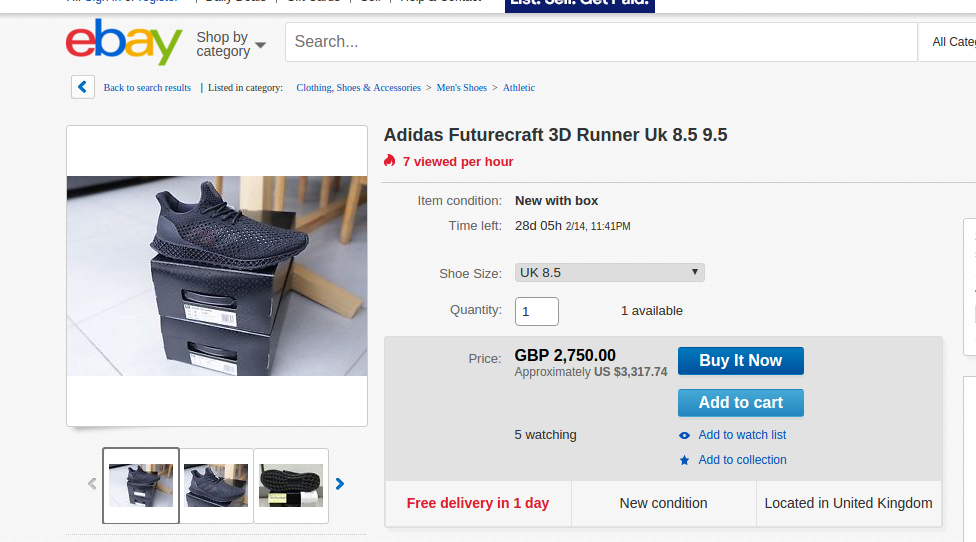

3D Runner

The 3D runner was released by Adidas in December. It was the first 3D printed trainer that Adidas sold with prior use of the technology only for prototyping. The product was used by Adidas to test the market and the technology. Retailing at $333 on release, Adidas’ 3D runner is currently selling on ebay in excess of $3,000. Which is a huge increase in value and is a result of the limited numbers released. However, with the rise of the Speedfactory technique Adidas will look to increase availability through mass production.

Adidas incorporating additive manufacturing

In their collaboration with environmental group Parley, Adidas used 3D printing for prototyping. Later in the year Adidas created a sneaker that included 3D printing in its final manufacturing. However, it was only released in New York, Tokyo and London stores with only 150 available. Moving into 2017, Adidas will be producing more 3D printed shoes by scaling up production of the Speedfactory.

Speaking in 2015, Gerd Manz, Vice President of Technology Innovation at Adidas explained their plans,

The set-up of the first SPEEDFACTORY has kicked off in Ansbach, Germany, to propel a global network of automated production which brings cutting-edge technology to cities around the world. These first 500 pairs will help us set the scene for large-scale commercial production so each consumer can locally get what they want, when they want it, faster than ever.

Why are they 3D printing?

One of the main reasons why Adidas are looking towards 3D printing as a manufacturing tool is for speed. Currently the time-scale of developing a new sneaker product can span over a year and Adidas want to reduce this time dramatically. Using 3D printing as both a prototyping tool and a manufacturing technique will enable that. 3D printing will also allow Adidas to shorten their supply chain and in the future they plan to expand this by offering bespoke designs, as we’ve seen with Rolls Royce, and customizable options.

Featured image shows Adidas Speedfactory robot. Image via Adidas.