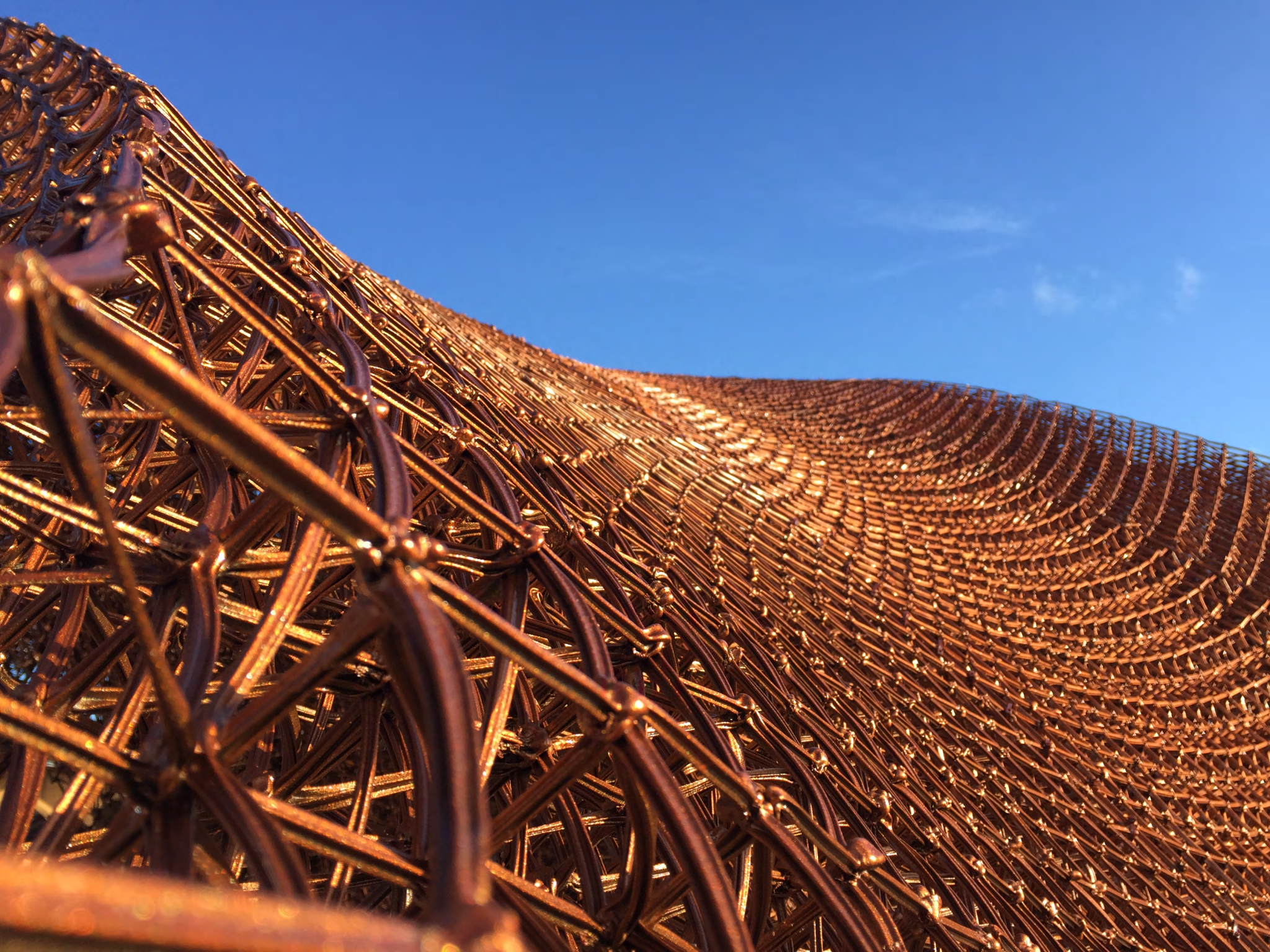

The largest 3D printed pavilions in the world were on display in Florida recently for the Design Miami exhibition. The structures were 3D printed and installed by 3D printing company Branch Technology from Tennessee, and designed by New York architecture firm SHoP Architects. In completing the project, Branch Technology 3D printed a total surface area of 2,753sqft.

We previously reported on SHoP Architects’ impressive plans for these pavilions, named ‘Flotsam & Jetsam’ prior to their completion. Now, with the exhibition having taken place during November 30 to December 4, we can report the pavilions which marked the entrance to the exhibition were a success.

SHoP Architects enlisted Branch Technology in order to manufacture the parts required for the structures. The architectural firm opted to use Branch’s Cellular Fabrication (C-Fab) technology due to the “speed of fabrication, customized flexibility with 3D printing, production cost, and installation timeframe.”

Branch Technology had just ten weeks to 3D print the structure, this included painting and then delivery to Miami. In order to fulfill the project, Branch added a two robotic 3D printing systems to meet their deadlines. The 3D print was finished with a copper fleck paint and assembled in just 4 days from a number of 3D printed parts.

SHoP Architects are also known for designing the Barclays Center, in Brooklyn New York: the home of the Brooklyn Nets NBA team. Following Design Miami, their Flotsam and Jetsam piece will be moved the to Miami Design District’s Jungle Plaza as part of “an outdoor cultural program” in partnership with Miami’s Institute of Contemporary Art.

At the exhibition SHoP Architects were honored with the Panerai Design Miami/ Visionary Award for their “signature employment of next-generation fabrication and delivery techniques, acute attention to detail and imaginative programmatic concepts.” This 3D printed structure is testament to their use of next-generation fabrication techniques and illustrates one way that 3D printing for construction can be used.

Oak Ridge National Laboratory (ORNL), also from Tennessee, participated in the project. ORNL provided the biodegradable bamboo filament for the furniture components. The national lab are also holders of the current Guinness World Record for the largest 3D printed structure to date. A feat Branch Technology were reportedly hoping to beat, however as the pavilions were assembled from a number of parts they did not qualify.

Make your nominations now for the 1st Annual 3D Printing Industry Awards. Nominations close soon.

Featured image shows Flotsam & Jetsam. Photo via Branch Technology.