Technology knowledge hub Wevolver and materials producer polySpectra have launched a 3D printing competition with a winning prize worth $25,000.

The Make it Real Challenge is inviting designers, engineers, and makers from around the world to create a unique product that takes advantage of polySpectra’s COR Alpha 3D printing polymer. Whichever entry is deemed to make the most of the new material, will receive $25,000 worth of additive manufacturing services to turn their idea into a physical product.

“COR Alpha took us more than five years of chemical research to develop,” said Raymond Weitekamp, Founder and CEO of polySpectra at the launch of COR Alpha. “The reception so far has been tremendous, and we are excited to be working with industry partners to help accelerate US innovation with our advanced materials for additive manufacturing.”

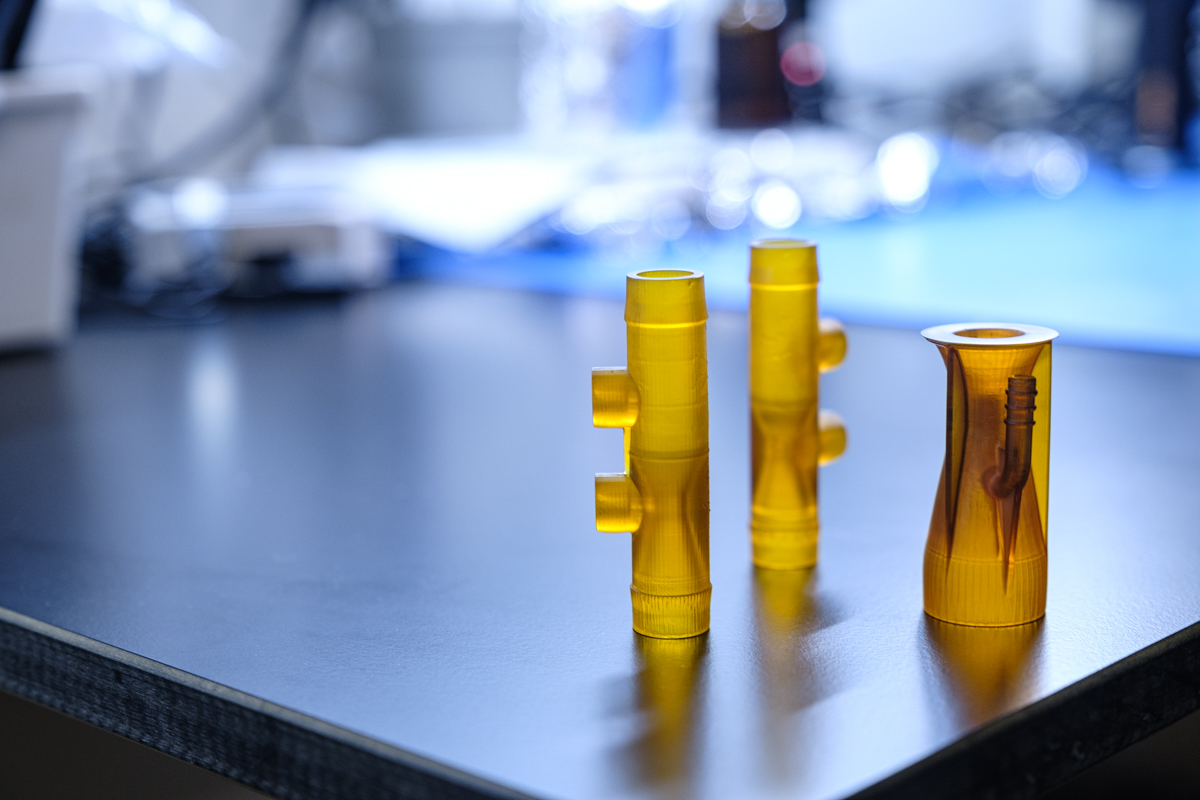

PolySpectra’s new COR Alpha material

COR, short for Cyclic Olefin Resin, is polySpectra’s first line of proprietary Digital Light Processing (DLP) 3D printing materials. The new thermoplastic reportedly provides the quality and strength of an injection molded part while offering the customization of 3D printing. Components produced using polySpectra’s thermoplastic are said to feature a high level of surface finish, durability, and thermal and solvent resistance.

The polymer has already been utilized in applications ranging from commercial products such as fashion items and electronic devices, to industrial parts like mounts, valves and fixtures. Now Wevolver and polySpectra are challenging design teams, engineers, inventors and startups to create products that can be amplified by COR Alpha 3D printed parts.

PolySpectra has released a series of videos to demonstrate the strength of 3D printed products created using its COR Alpha material. Depicted as ’rounds’ in a boxing match, the thermoplastic parts manage to withstand the grinding blades of a blender, boiling water, an acetone soaking and a hairdryer.

The Make it Real Challenge brief

Applicants can either choose to enter a stand-alone product, or a component as part of a larger design. The winning entry will be chosen based on how well the creation takes advantage of COR Alpha’s qualities, as well as its creativity and suitability for additive manufacturing. The technical specifications for entry are as follows:

- All designs must be submitted as fully realizable STL files

- Parts must be able to fit into a 190mm x 120 mm x 200mm build envelope

- All team members must be available during the challenge to collaborate with polySpectra and Wevolver

The full benefits of the $25,000 winning prize

The winner of the Make it Real Challenge will receive $25,000 worth of polySpectra’s production 3D printing services, in addition to its full support in turning their idea into a functional reality. PolySpectra will provide the following services to the competition’s winning designer:

- Mentorship

- Design consulting for additive manufacturing

- Functional prototyping

- Qualification of the printed parts

- Testing of the final product

- Full production of the winning design

Entering the Make it Real Challenge

All entrants must include the following information in order for their design to be admissible:

- The personal details of all team members

- A description of your submission idea

- An outline of how your design takes advantage of COR Alpha’s properties and why COR Alpha can make your idea real

- Images that strengthen your submission – e.g. screenshots, illustrations, drawings

- A submitted entry in the form of a realizable STL file

Applications for the competition close on September 28 2020 at 12pm (PT), and entrants should apply now to avoid disappointment. Interested parties can apply via the short form on polySpectra’s website. Shortlisted finalists will be contacted in October 2020, before the winner is revealed in November 2020.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a selection of parts produced using polySpectra’s COR Alpha 3D printing material.