SHoP Architects, a New York based architecture practice, will celebrate winning The Panerai Design Miami/ Visionary Award with a 3D printed pavilion on display at the city’s Jungle Plaza.

The structure is inspired by Miami’s coastal location, and created with SHoP’s core values in mind. “Form comes from how the building works: What’s the effect we want the building or the structure or object to have? What does it feel like? What does it do?” explains SHoP co-founder Gregg Pasquarelli.

Hence the name: Flotsam & Jetsam – the structure allows people to leisurely ‘float’ through it as they go about their business.

FloandJet will be printed using a biodegradable bamboo filament provided by Oak Ridge National Laboratory (ORNL). ORNL are the current Guinness World Record holders for largest 3D printed structure, a feat that SHoP expect to smash with this new construction.

The architects at SHoP are collaborating with Branch Technology for the fabrication process, and the influence is evident in the truss-like design of Flotsam and Jetsam. Branch Technology were started by R. Platt Boyd, an award winning architect who has a “fascination with the natural world and interest in both 3D printing and robotics.”

This intersecting style of structure is key to the way in which Branch Technology are seeking to reinvent the way the world builds its structures. When talking to 3DPI in July 2015, Platt Boyd of Branch Technology told our journalist,

“Did you know, that the way we construct buildings hasn’t really changed for 10,000 years? The oldest extant structures are about 10,000 years old and those are post and beam. And we’ve been doing it that way for a long, long time, with some deviation, but not a lot. But they don’t really translate how structures are formed in the natural world.”

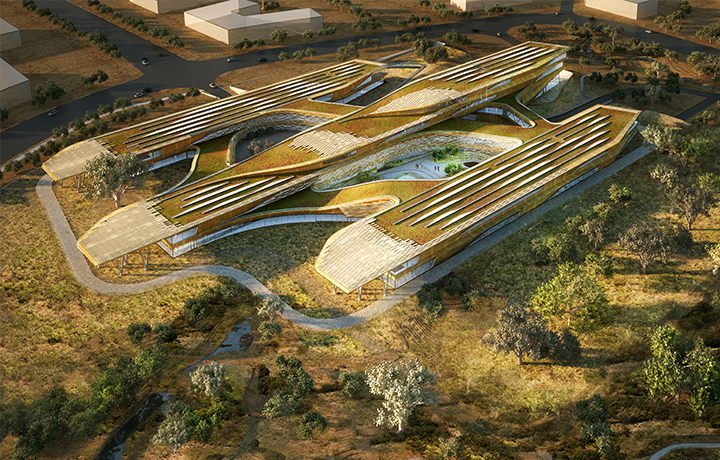

Such innovative practice and entrepreneurship is one of the reasons why SHoP won the award. They were also commended for their ‘sustainable development’, presumably reflected in the use of bamboo material, but certainly demonstrated in the Botswana Innovation Hub which is currently under construction.

Flotsam and Jetsam is certainly an inspired and decidedly ‘bold’ design. It evokes a futuristic vision of how spaces are transforming and is exciting where the future of 3D printing for construction is concerned. Combined with this year’s earlier announcement that Dubai will soon be printing whole buildings, we are expecting to hear much more about 3D printed architecture in the very near future. Click here to be the first to receive news like this in your inbox.