Our latest digest of 3D printing news put through the slicer includes: Maryland and North Carolina based 3DP bureau vacancies, a scanning software Kickstarter, updates to Harvard’s Octobot, 3D printed sailboats with Land Rover, more 3D printed parts for Airbus and 3D printed Adidas sneakers now available for purchase.

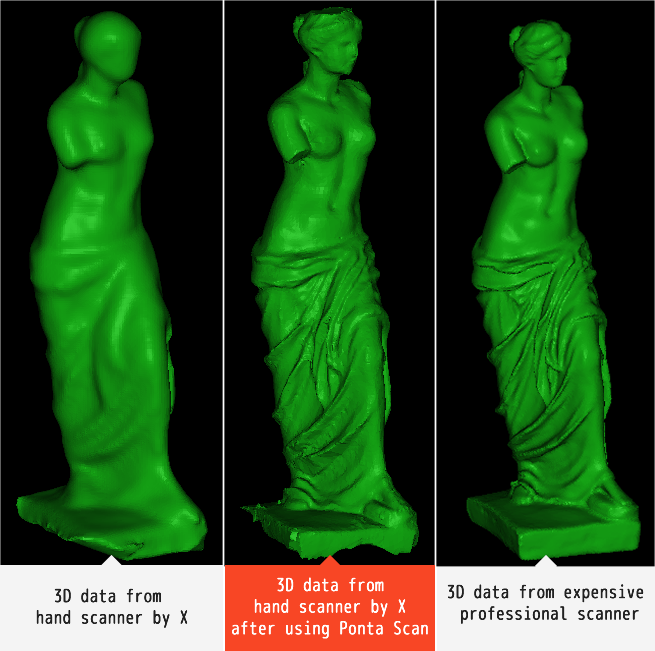

Ponta scan on Kickstarter

Japanese company Ponta Scan are currently crowdfunding with the goal of $10,000 in order to supercharge existing scanners: turning data from a small handheld scanner into professional level scans through new 3D processing technology. Ponta Scan software is for Windows and can take raw data from an inexpensive scanner and bring it to a competing level with the professional scanners.

Octobot update

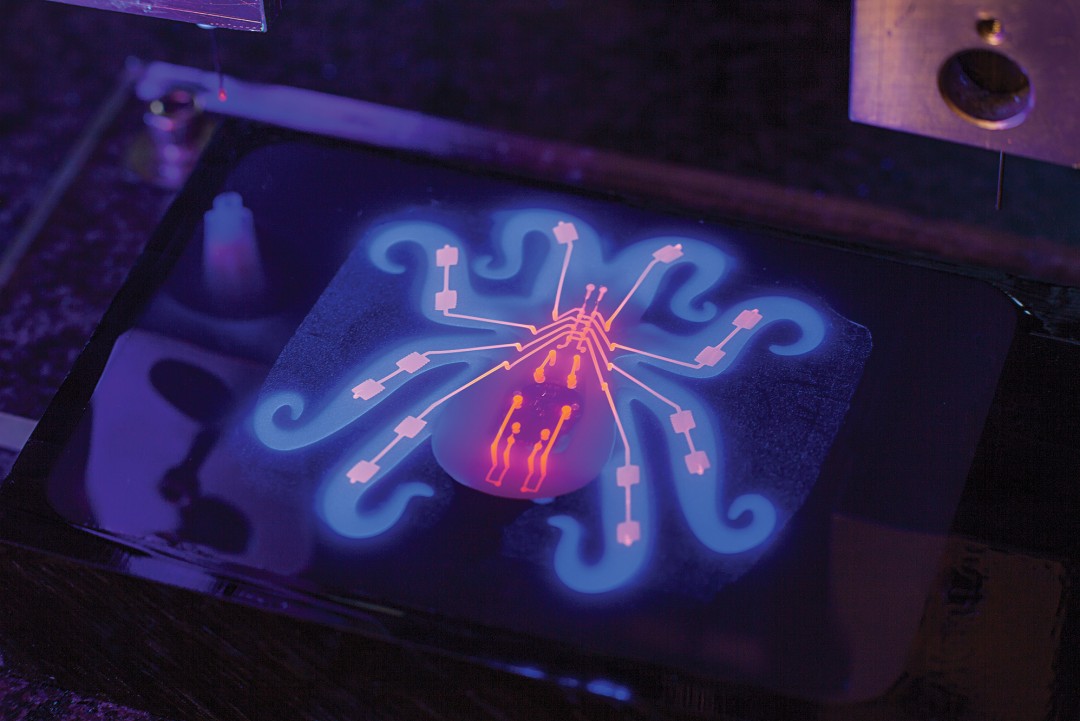

New information about Harvard’s Octobot has been released, revealing more about the process of printing the soft-robotic cephalopod.

Firstly, a mold is filled with silicone and all the air bubbles are sucked out. A 3D printer then prints two types of ink onto the mold, one to be evaporated to create particular holes inside the robot, and the other a platinum ink to perform the reaction needed to set the bot in motion. Finally, the octopus is baked for four days in order to seal the materials in place. Upon completion, rocket fuel is to added as the final ingredient and the tentacles move.

Land Rover BAR boats

Sporting team Land Rover BAR have utilized 3D printing in order to sail ahead of their competition. Through their partners Technical Innovation Group and Renishaw, the commercial sporting team have been able to adopt additive manufacturing to print custom maritime parts.

Chief Technology Officer at Land Rover BAR, Andy Claughton explains the novel approach as follows:

It allows us to get our hands on it, put it in place on the boat or link it up with other parts of the system and see potential issues and refine the design before we commit to the production of the final piece.

Job openings at Xometry

Maryland-based 3D printing bureau Xometry, are looking for project and software engineers, marketers and manufacturing personnel, in Gaithersburg, Bethesda and Durham, NC. With over 20 vacancies available it could be the perfect opportunity for anyone looking to get their get break into the industry.

Arconic and Airbus

Arconic (NYSE:ARNC) are furthering their collaboration with Airbus with new agreements to 3D print nickel and titanium parts for Airbus planes. North American Arconic are a global engineering and 3D printing company and will supply components for the A320 planes starting in 2017.

You can now buy 3D printed sneakers

Adidas are releasing the ‘3D printed runner’ sneaker to consumers this week. Having recently released the Parley shoe which was developed with 3D printing as a prototyping tool, Adidas are now releasing a product that has 3D printing in its final design. The shoe will be priced at $333, a nod at the technology involved, and is the same shoe which was awarded to Rio 2016 athletes.

To receive our updates directly to your mailbox, readers can sign up to the daily 3DPI newsletter here.

Featured image shows the Sliced logo over Harvard’s Octobot. ‘The colors here show the alternating routes that the gas can take through the bot, moving half of the tentacles at a time and helping it wiggle.’ Original photo and quote from: MIT Technology Review (technologyreview.com)