Meet Octobot! This amazing robot is the first autonomous, entirely soft robot, and was created by a team of Harvard University researchers.

The Octobot is inspired by octopuses, and could revolutionize they way humans interact with machines. Until now, soft bodies robots have had to be tethered to an off-board system or rigged with some hard components, like batteries and circuit boards. Creating entirely soft robots was extremely challenging, and according to the researchers has never been achieved before. The Octobot changes this.

The team behind Octobot

Wyss Core Faculty members Robert Wood, Ph.D., and Jennifer Lewis, Sc.D., led the project. Respectively, they are also the Charles River Professor of Engineering and Applied Sciences and the Hansjörg Wyss Professor of Biologically Inspired Engineering at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS). The Octobot is described in the journal Nature, and has already been well received.

“One long-standing vision for the field of soft robotics has been to create robots that are entirely soft, but the struggle has always been in replacing rigid components like batteries and electronic controls with analogous soft systems and then putting it all together,” said Wood. “This research demonstrates that we can easily manufacture the key components of a simple, entirely soft robot, which lays the foundation for more complex designs.”

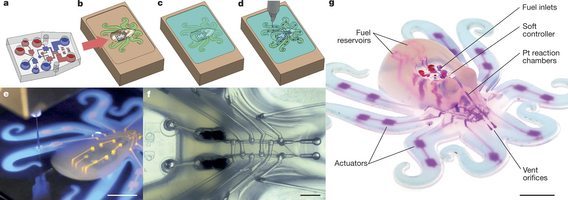

“Through our hybrid assembly approach, we were able to 3D print each of the functional components required within the soft robot body, including the fuel storage, power and actuation, in a rapid manner,” said Lewis. “The octobot is a simple embodiment designed to demonstrate our integrated design and additive fabrication strategy for embedding autonomous functionality.”

How does Octobot work?

Harvard’s Octobot is pneumatic-based, meaning it is powered by gas under pressure. A reaction inside the bot transforms a small amount of liquid fuel (hydrogen peroxide) into a large amount of gas, which flows into the Octobot’s arms and inflates them like a balloon. The reaction is controlled by a 3D-printed microfluidic logic circuit – described as a “soft analogue of a simple electronic oscillator” – which controls when hydrogen peroxide decomposes to gas.

“Fuel sources for soft robots have always relied on some type of rigid components,” said Michael Wehner, a postdoctoral fellow at the Wyss Institute and in the Wood lab and co-first author of the paper. “The wonderful thing about hydrogen peroxide is that a simple reaction between the chemical and a catalyst — in this case platinum — allows us to replace rigid power sources.”

“The entire system is simple to fabricate, by combining three fabrication methods – soft lithography, moulding and 3D printing,” said Ryan Truby, a graduate student in Lewis’s lab, and a co-author of the paper. “We can quickly manufacture these devices.”

“This research is a proof of concept,” Truby said. “We hope that our approach for creating autonomous soft robots inspires roboticists, material scientists and researchers focused on advanced manufacturing.”

The team hopes to create an Octobot that can swim and crawl, as well as interact with its environment.

The paper was co-authored by Daniel Fitzgerald of the Wyss Institute and Bobak Mosadegh, of Cornell University. The research was supported by the Wyss Institute and the National Science Foundation through the Materials Research Science and Engineering Center at Harvard.

About the Institutes involved

The Harvard John A. Paulson School of Engineering and Applied Sciences serves as the connector and integrator of Harvard’s teaching and research efforts in engineering, applied sciences, and technology. Through collaboration with researchers from all parts of Harvard, other universities, and corporate and foundational partners, they bring discovery and innovation directly to bear on improving human life and society.

The Wyss Institute for Biologically Inspired Engineering at Harvard University uses Nature’s design principles to develop bioinspired materials and devices that will transform medicine and create a more sustainable world. Wyss researchers are developing innovative new engineering solutions for healthcare, energy, architecture, robotics, and manufacturing that are translated into commercial products and therapies through collaborations with clinical investigators, corporate alliances, and formation of new startups. The Wyss Institute creates transformative technological breakthroughs by engaging in high risk research, and crosses disciplinary and institutional barriers, working as an alliance that includes Harvard’s Schools of Medicine, Engineering, Arts & Sciences and Design, and in partnership with Beth Israel Deaconess Medical Center, Brigham and Women’s Hospital, Boston Children’s Hospital, Dana-Farber Cancer Institute, Massachusetts General Hospital, the University of Massachusetts Medical School, Spaulding Rehabilitation Hospital, Boston University, Tufts University, Charité – Universitätsmedizin Berlin, University of Zurich and Massachusetts Institute of Technology.

Featured image: Lori Sanders