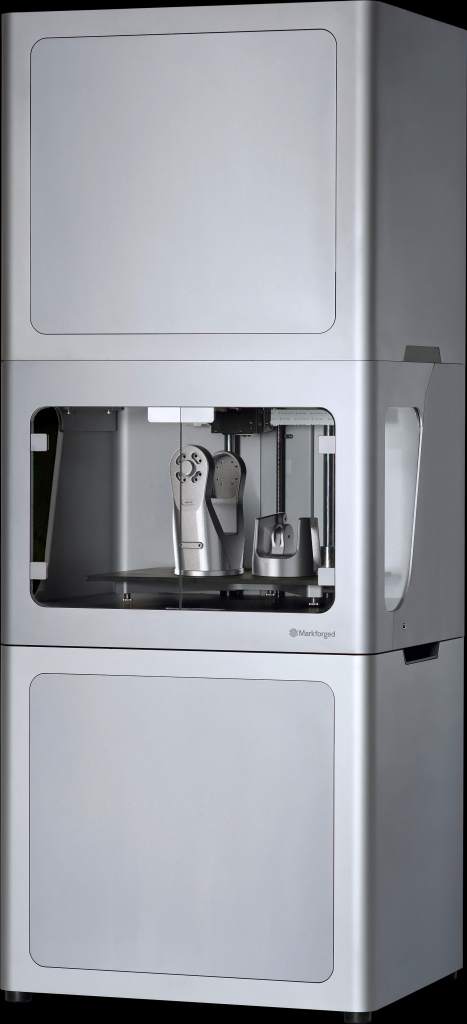

At CES 2017 today Markforged have announced what might be a revolution in 3D printing, a desktop metal 3D printer called the Metal X.

3D metal printing materials useable by the Metal X include, 17-4 Stainless Steel, 303 Stainless Steel, 6061 Aluminum (Beta), 7075 Aluminum (Beta), A-2 Tool Steel (Beta), D-2 Tool Steel (Beta), IN Alloy (Inconel) 625 (Beta) and Titanium Ti-6Al-4V (Beta). This is an incredible range of metal materials that not even some of the more established existing industrial machines can accomplish.

Of the launch materials the company say,

303 stainless steel is great for post processing in CNC milling and turning operations. It maintains corrosion resistance up to 800C. We use it in the drive roller for our fiber system on the Mark X. 17-4 stainless steel combines high strength, corrosion resistance, and hardness, making it widely used in aerospace, medical and petroleum industries. We use it for assembly fixtures and tooling on the Mark X.

Markforged were founded by Greg Mark, an MIT aerospace engineer with a keen interest in motorsports racing in 2013. “If you can afford a half million to million dollar metal printer, buy one. For the rest of the World, this is for you,” said Greg Mark regarding today’s announcement.

The ADAM 3D printing process

The secret to bringing 3D metal printing to the desktop is the Atomic Diffusion Additive Manufacturing (ADAM) process. According to the company this creates, “a part using a bound metal powder rod that transforms into a dense metal part in one easy step. Bulk sintering provides crystal growth through all axes giving your parts excellent mechanical properties in all directions.”

The ADAM process allow for the creation of complex geometries and closed-cell honeycomb infills. Current DMLS metal additive techniques are unable to recreate this particular geometry, nor can traditional subtractive manufacturing techniques.

The company’s existing range of 3D printers can work with continuous Carbon Fiber, Kevlar and (High Temp) Fiberglass materials.

Metal X Specifications:

Footprint: 575 mm x 467 mm x 1432 mm;

Build volume: 250 mm x 220 mm x 200 mm (WDH);

Materials:

17-4 Stainless Steel

303 Stainless Steel

6061 Aluminum (Beta)

7075 Aluminum (Beta)

A-2 Tool Steel (Beta)

D-2 Tool Steel (Beta)

IN Alloy (Inconel) 625 (Beta)

Titanium Ti-6Al-4V (Beta)

Resolution: 50-microns

Software Features:

Single Sign-On

Two-Factor Authentication

Organization Admin Portal

Early Access to New Features

Software Delivery:

SaaS deployment and storage

Local Storage

Fully On-premise

We will bring you more information about pricing and when the first units will ship as we have it.

Does this news get your nomination for the 1st Annual 3D Printing Industry Awards, make your choice here and don’t forget to subscribe to our newsletter for all the latest about the 3D printing industry.

Update

Pricing & Availability

The Metal X starts at $99,500 and is available to order now with the ability to print high-end stainless steels 17-4 and 303. It will ship in September.

The Metal X and Mark X, the Markforged $69,000 industrial-grade carbon fiber 3D printer, are available in a bundle starting at $149,000. This package enables 3D printing of everything from plastic to metal to carbon fiber.

Purchasers of the Metal X may apply to participate in the Metal Materials Beta program, extending the metal options to include Tool Steel (A-2, D-2, M-2), Aluminum (6061, 7075), and Titanium (6AL 4V).