Dutch 3D printing company, Admatec Europe BV has launched a new metal 3D printer, the ADMETALFLEX.

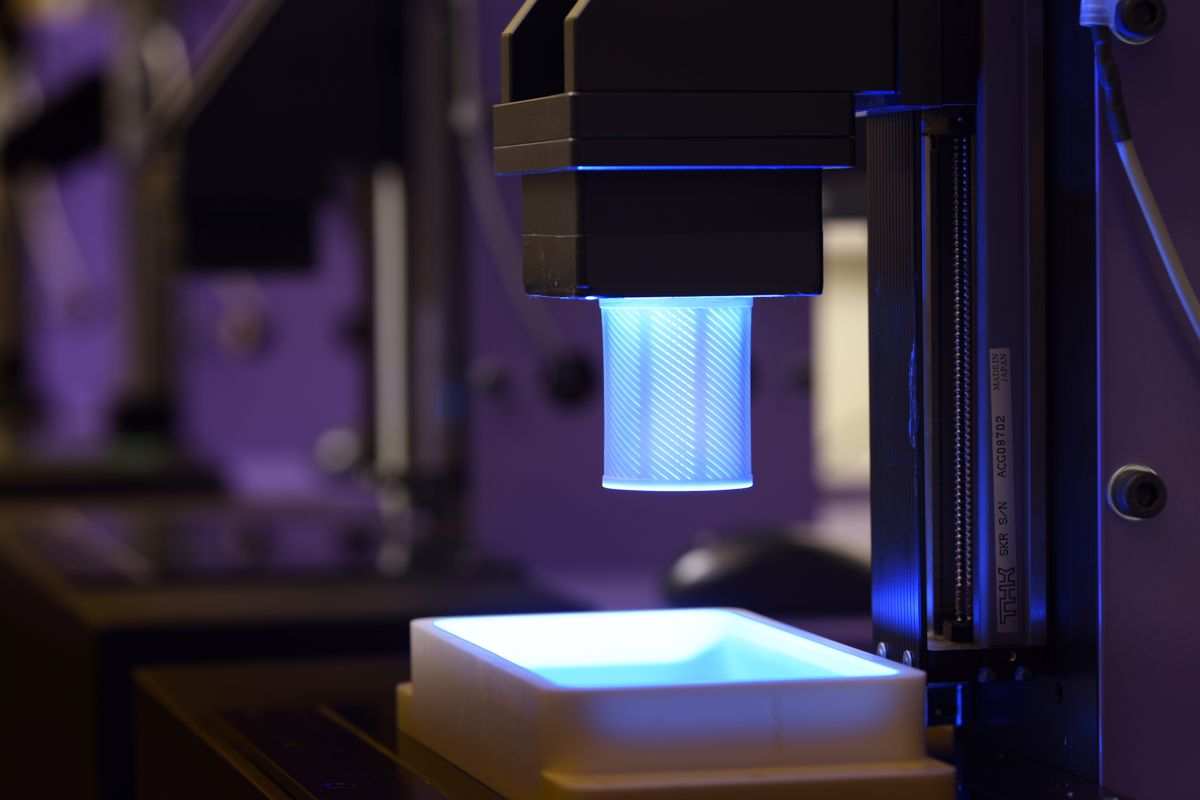

The company was founded as a result of a research project with the Energy Research Centre of the Netherlands (ECN) and Admatec now makes use of this relationship to develop new technologies. The ADMETALFLEX uses Digital Light Processing (DLP) technology to 3D print metal from a resin formulation.

From ceramics to metal

The company unveiled their ceramics 3D printer last September and have now ventured into metal with the new ADMETALFLEX 3D printer. This new machine is also part of the ADMAFLEX technology series which utilizes DLP to create prints. With their ceramics 3D printer Admatec infuses a photosensitive resin with ceramic powders and then debinds and sinters the material in post-processing.

As we recently reported, researchers in China are the use of magnets to create ‘smart materials’ for SLA 3D printing. Introducing metal, or ceramics into a resin can present problems in particular agglomeration, or uneven dispersal of material. The Chinese research used magnets to address this issue, while the ADMETALFLEX works on a high throughput basis. By having a high throughput of materials it is also possible to work with more novel photo-polymers, as demonstrated by 3D Systems’ figure 4 configuration.

ADMETALFLEX

Advances in 3D printing materials are a driving force in bringing 3D printing metal to a wider group beyond the industrial scale machines. For example, in the FDM segment The Virtual Foundry has introduced materials that can be used to create metal 3D prints using desktop machines.

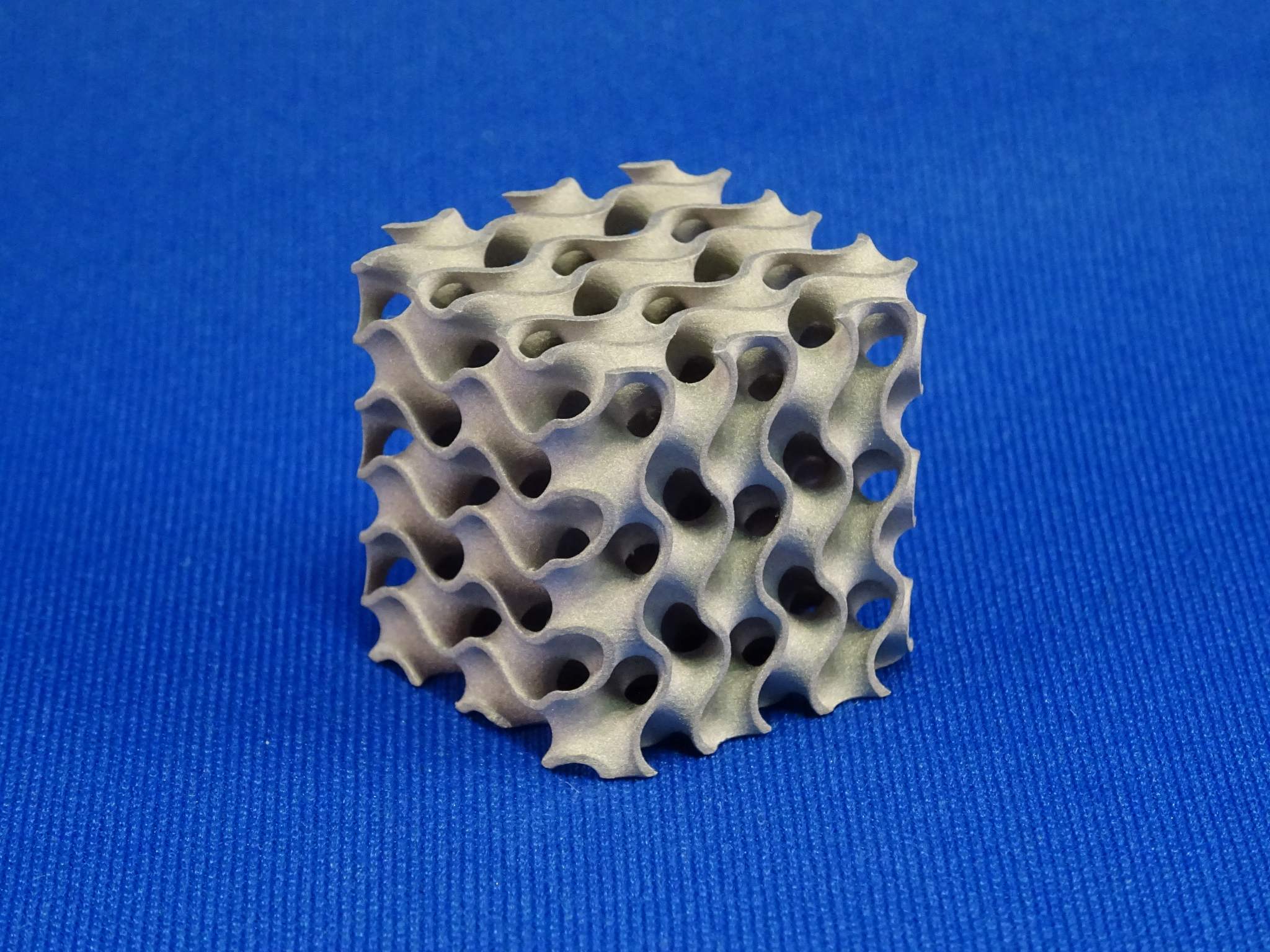

While not the only part of the process that allows 3D printing of metal with an SLA machine, the ADMETALFLEX does owe some of its ability to the resin formulation. Once the 3D print is complete it must undergo further processing to remove the plastic from the metal material in a debinding procedure. During a sintering process the 3D print becomes a fully dense material. With this process ADMAFLEX claim that the creation of precise, high-performing metal structures is possible. We’re keen to get our hands on a machine to test this for ourselves.

Jaco Saurwalt, director of the engineering & materials department at ECN, said

High-material quality combined with form freedom and fine product details were the goal of our development. By improving both the process as well as the machine the current ADMATEC ceramics printing technology has been extended to high-density metals.

Approaching market

With this new 3D printer, Admatec aims to address the metal injection molding (MIM) market. The injection molding market is ripe for disruption and during 3D Printing Industry’s recent visit to HP’s Corvallis facility a substantial amount of conversation revolved around what advances in 3D printing will mean for this manufacturing process.

One of HP’s longer term goals is to increase the point where their Multi Jet Fusion technology is more economic than injection molding. Currently HP state that MJF beats injection molding, on price, for production runs of up to 50,000 units. In the future HP plan to increase this unit count to 1 million.

It will be interesting to see how the two companies compete with the traditional manufacturing techniques with these new 3D printers. For most commentators, a combination of additive and traditional or subtractive processes is a more likely scenario than the outright replacement of manufacturing by 3D printing.

Michiel de Bruijcker, managing director of ADMATEC, explained

With this product, Admatec is underlining its strong cooperation with ECN and the dedication to push the ADMAFLEX technology to more applications and broader market acceptance. Pulling off this task will strengthen ADMATEC’s market position as a leading additive manufacturing brand!

Don’t forget to cast your vote in the 3D Printing Industry Awards.

For the latest 3D printing news, follow us on twitter and sign up to our newsletter.

Featured image shows 3D prints from the AdMetalFlex