Already known adopting 3D printing in various respects, aircraft manufacturer Boeing is driving 3D printing innovation further by patenting a new 3D printing technology that actually prints objects while they are floating in midair. That’s right; this newly patented technique is meant to 3D print objects while that particular object is simultaneously levitating …

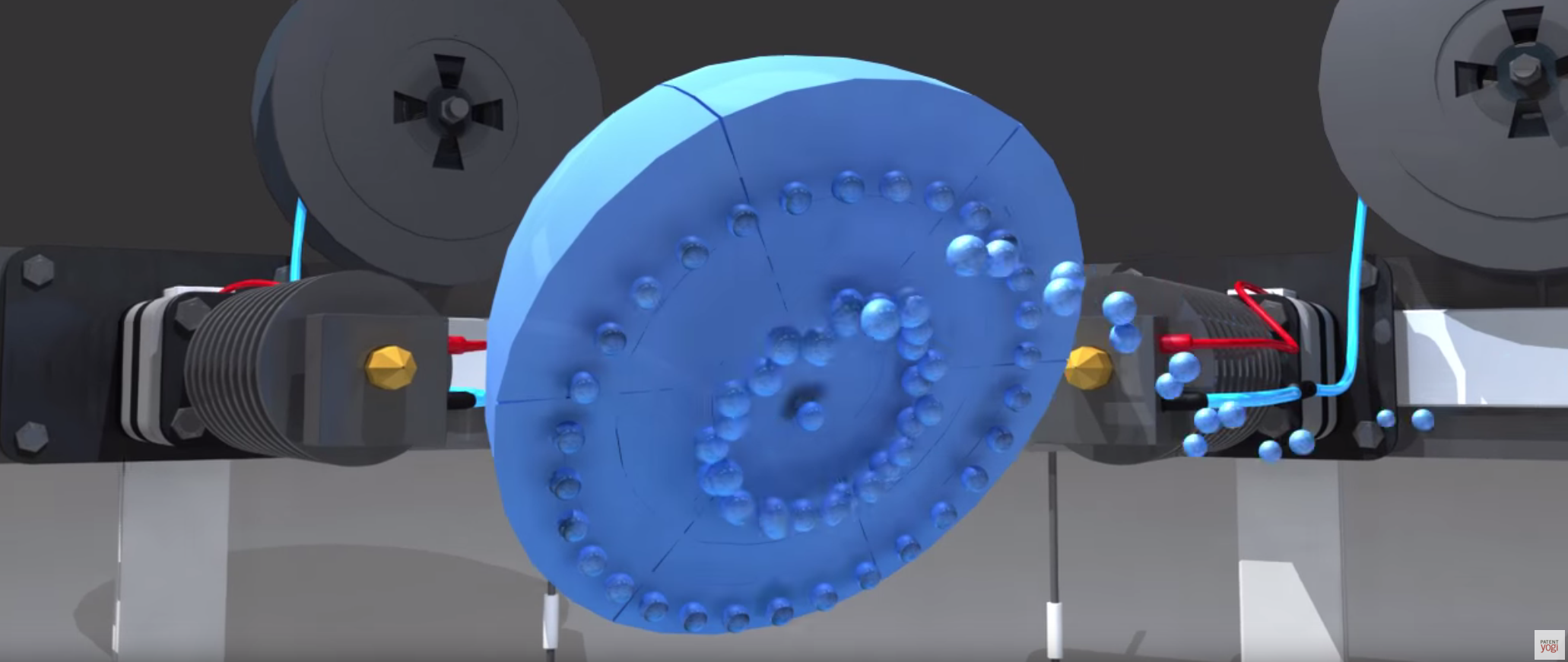

This technology is like one I’ve never personally seen before, utilizing multiple 3D printers at once to extrude material with diamagnetic properties. Instead of using a build plate, Boeing’s technology creates magnetic fields that hold the first bit of 3D printed material (called the ‘nugget’ by Boeing) in place, which is then built upon by the multiple 3D printers involved in the process.

Boeing explained the need for this type of process within their recently published patent: “There is a need for an AM method and apparatus that eliminates the need for a platform and/or support materials to stabilize the part during the fabrication process, and which removes limitations on the types of features that can be formed, allowing full body 3D printing of complex parts.”

Now, you may be wondering what the actual benefits of a levitating 3D printing processes may be in space, besides sounding really awesome. As a matter of fact, there are quite a few… Since the ‘nugget’ is held up by magnetic fields, the printers can deposit materials on either side of the base, unlike conventional 3D printers that use bottom-up printing. These magnetic fields also allow the 3D printed ‘nugget’ to be rotated in any direction, which allows for much more complex shapes and features within the 3D printed object. Another distinct advantage of Boeing’s new 3D printing technology is that, since it uses multiple 3D printers at once, the print speed is also greatly increased.

The patent, which was officially published early this month, is entitled “Free-Form Spatial 3-D Printing Using Part Levitation” and can be viewed in its entirety here. Boeing plans to further develop and utilize their new 3D printing process to 3D print aircraft parts. Patent Yogi has put together a great visual representation of how Boeing’s patented 3D printing technology works, which can be viewed above. It’ll be interesting to see in which ways this technology will improve the function of conventional 3D printing technology. Much like their high-flying aircraft, Boeing is making an exciting push towards literally taking 3D printing technology off of the ground (or off of the build plate, if you will).