If there were any lingering doubts as to the potential usefulness of 3D printing technologies, the e-NABLE network and Robohand projects are rapidly erasing them. Self made, open source, custom and affordable prosthetics is probably the single field where the benefits of 3D printing are more evident and the possibilities opened up by these initial projects are rapidly expanding worldwide, with the new Kenya based 3D Life Prints initiative being the latest to join the ranks.

In some countries of the developing world, 3D printing is going to bridge the manufacturing gap just like mobile technologies have contributed to bridging the technological gap. Kenya is the country with more pro capita mobile phones and one of the first where mobile phone payments became commonplace. Nairobi is one of Africa’s leading technological hubs (with Google, Cisco and Nokia Siemens building HQ’s there) and the adoption of digital manufacturing is a natural step.

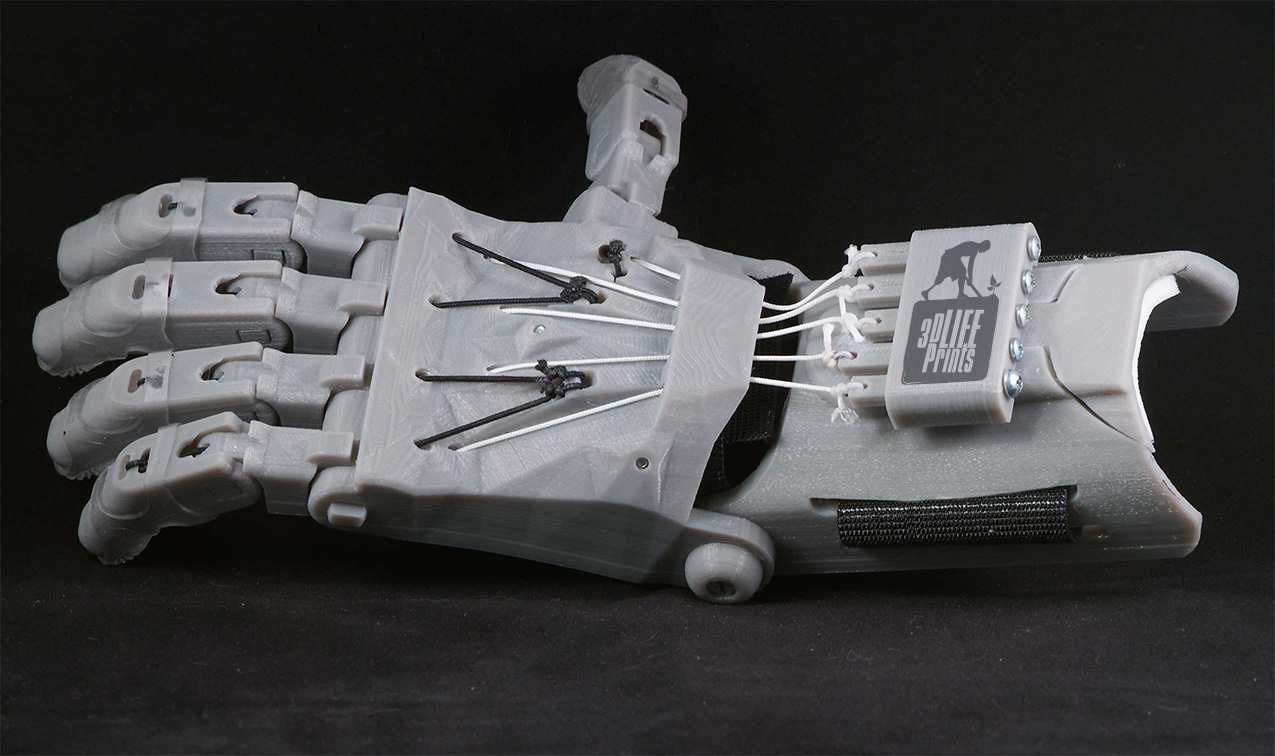

In fact, compared with other successful initiatives that began producing prostheses for amputees in Africa such as Robohand and Project Daniel, 3D Life Prints is taking a more technological approach by creating a sustainable operational service framework and by creating cases for recipients through a custom digital system, which also implements SMS communication channels for pre and post care, using local resources wherever possible. This means that all client customizable records (including biometric body scans and location data) are entered into an online system by using mobile devices. The data is securely stored into a Cloud platform and can be accessed anywhere.

This support system adds up to 3D Life Prints’ main services, which include mobile 3D scanning through 3D Systems portable Sense system, 3D modeling and design to adapt the freely available prosthetic models such as e-NABLE’s Raptor to individual needs and body shapes The model manufacturing is achieved through an easily transportable Ultimaker 2 system, which makes the entire project easy to move and adapt even within remote regions.

To think that for less than $3000 today, it is possible to create a moving, customized prosthetic factory anywhere in the world is amazing. In the 3D printing Industry we sometimes tend to consider such new possibilities almost commonplace, but only a couple of years ago they would have been considered just an impossible dream. And a great example to mention to the next person that tells you something is impossible.