Although some other sectors such as aerospace and biotechnology make the 3D printing news more often, the automotive industry is the biggest adopter of 3D printing technologies and has been one of the main drivers for their growth and evolution for close to thirty years. According to a new report by SmarTech Market Publishing, the automotive sector is going to continue to lead in 3D printing adoption and applications for the next five years, reaching $1.1 billion in terms of global turnover directly linked to 3D printing.

The “Additive Manufacturing Opportunities in the Automotive Industry: A 10 Year Forecast”, authored by Senior Analyst (and author of 3DPI’s “Professional 3D Printing Competitive Intelligence Report: A Competitive Resurgence”) Scott Dunham, focuses on how the automotive industry is currently switching from the use of 3D printing for individual or very low numbers of prototypes to series manufacturing of final parts, which are also progressively getting larger in terms of manufactured units.

Dunham reports that several large manufacturers are additively producing as many as 100,000 parts per year and that these leaders are carrying the rest of the industry with them. Some time ago, we reported on Ford as one of those manufacturers and we are also constantly reminded of how low-unit car manufacturers, such as Ferrari and Lamborghini, are increasing their adoption of 3D printing technologies.

As they implement 3D printing, these companies are raising the standards in terms of materials optimization, part personalization, and production efficiency. This will drive more and more companies to expand their 3D printing capabilities with the sale of industrial 3D printing hardware set to reach $586 million globally by 2019.

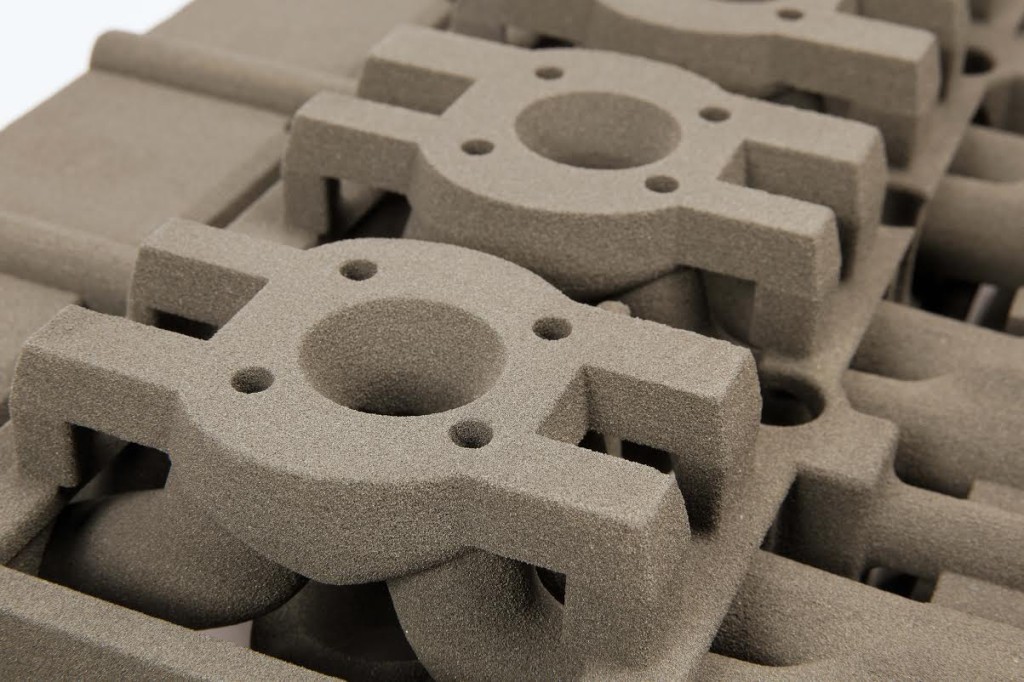

More 3D printers at work will also mean a higher demand for 3D printable materials, thus growing global revenues for this particular segment of products to $386, just in the automotive sector. While thermoplastics for FDM and photopolymer materials for stereolithography-based technologies will continue to represent the majority of these materials, sand for 3D printed molds will also be growing at a very rapid pace.

No mention was made of metals in the report overview, however that might not represent a primary issue, as the trend in the automotive sector is to gradually replace metals with high performance polymer and composite materials. In this regard, startups and increased R&D will contribute to an ever growing number of final parts made by 3D printing in a wider number of cars. Or perhaps even entire cars themselves.