Researchers from Xiamen University have 3D printed radio frequency (RF) probe heads capable of performing both routine and unconventional Magnetic Resonance (MR) experiments.

MR technology is widely deployed within scientific research, geological surveys, and clinical diagnosis, such as MRI scans. RF probe heads are core components of MR systems and are typically used to carry out electrochemical analysis, in-situ reaction monitoring, and MR imaging.

Using 3D printing, Xiamen’s researchers have developed a method to build customized RF probe heads with more precisely adapted coil structures than is currently possible with conventional manufacturing techniques. According to them, this study is the first to explore this type of method for the fabrication of integrative probe heads for MR systems.

3D printing the RF probe heads

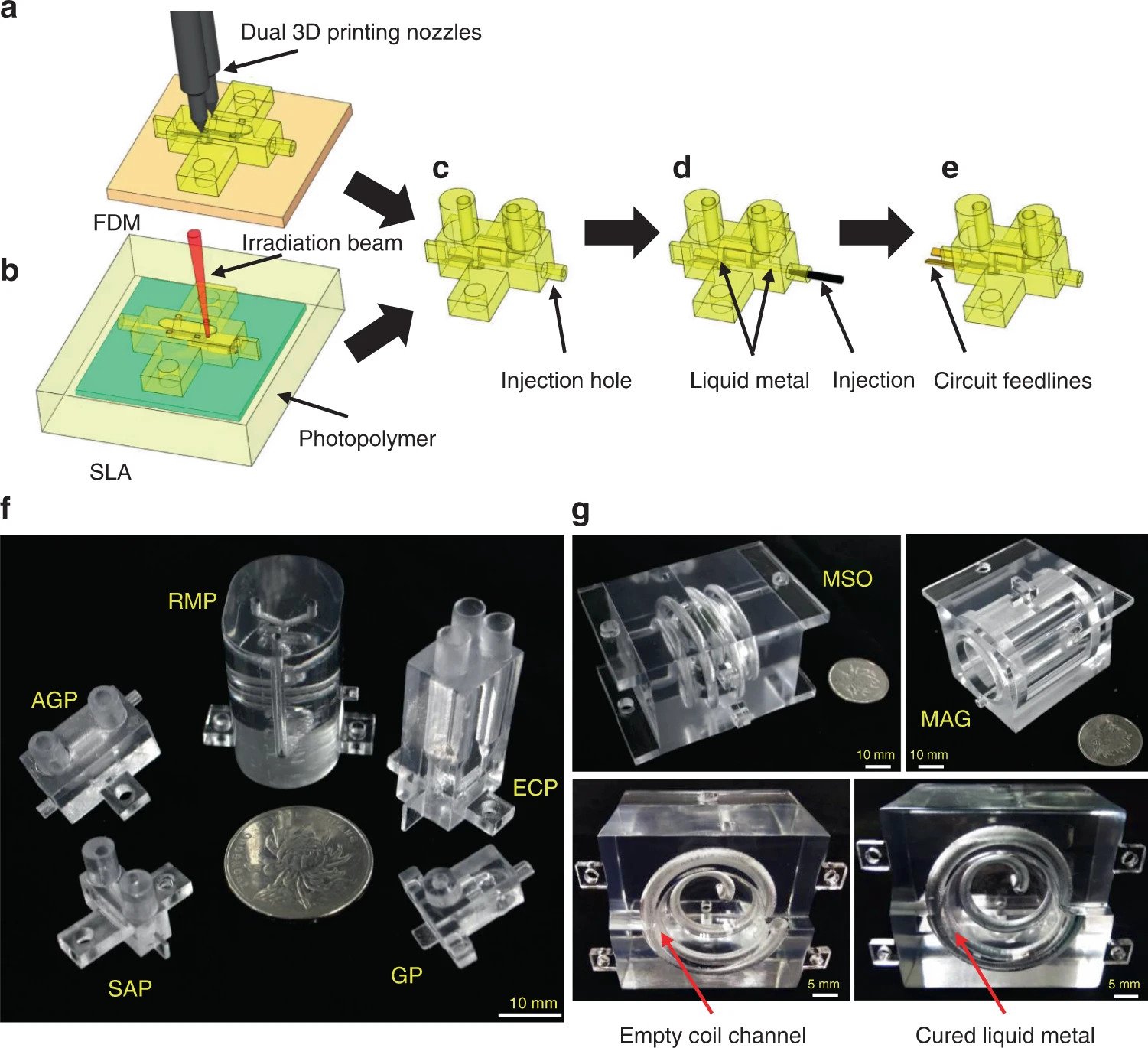

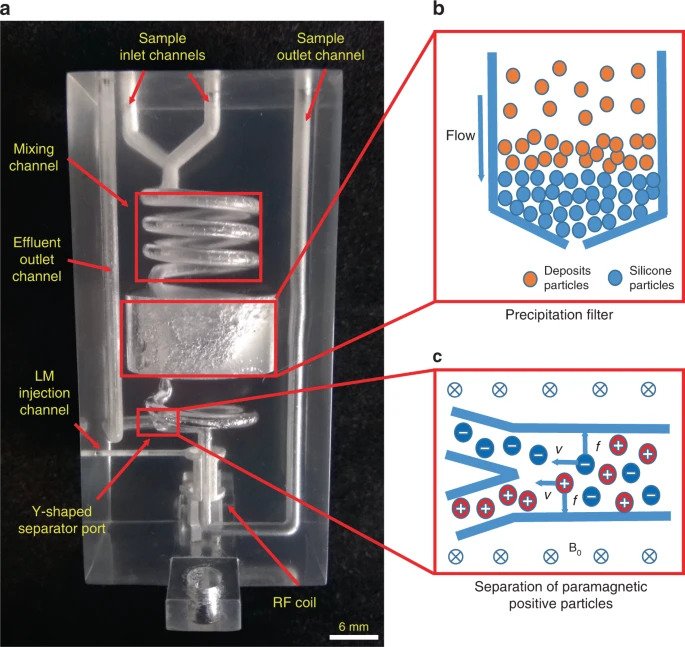

During the study, the researchers demonstrated a method that combines computer-aided design (CAD), 3D printing, and liquid melting injection techniques to create the integrative MR probe heads. Both Fused Deposition Modeling (FDM) and Stereolithography technologies were used to fabricate the probe heads, which consisted of an RF coil with micrometer-scale conductive wires, customized sample chambers, and RF circuit interfaces, wrapped inside a single printed polymer block.

3D Systems’ ProJet 3510 SD 3D printer was used to fabricate one version of the MR prototypes via FDM with a printing resolution of 30 µm. During printing, material was extruded from one of the printer’s dual nozzles to construct the molding structures and the hollow coil cavities. For the Stereolithography-produced probe heads, printed on a Cyclone W-1 printer from Jiaxing Shanwei Electrical and Mechanical Co., the models were created layer by layer via photopolymerization with a printing resolution of 25 µm. A UV laser was focused on a vat of photopolymer resin, causing chains of molecules to link to form polymers, which made up the bodies of the probe heads.

After the probe heads were printed, they underwent post-processing before the conductive RF coils were created using a liquid metal perfusion technique. These were then injected into micro-channels within the 3D printed polymer block, which was printed using transparent materials in order to illustrate its internal channel structures. The material of choice for printing the probe head was PLA, after experiments showed it performed well in terms of both electrical performance and material background signals.

A variety of probe heads were printed to investigate different in-situ reactions, such as kinetics monitoring, electrochemical reaction monitoring, nuclear magnetic resonance (NMR), and imaging.

Potential applications

In addition to the experiments mentioned above, the researchers sought to demonstrate the universal applicability of their approach through custom-designing the probe heads. Performance tests indicated that, despite some disadvantages in the conductivity of the coil materials, the 3D printed probe heads obtained images with higher signal-to-noise (SNR) ratio. According to the researchers, this means the method has “great prospects” for custom MRI applications.

The team focused their approach on addressing the precision and integrated custom machining drawbacks encountered by conventional manufacturing methods of RF probe heads, rather than optimizing the performance of their 3D printed alternatives. The fabrication of RF probe heads through current methods faces difficulties in terms of integration, customization, and miniaturization. Essentially, it is imprecise and time-consuming to manufacture RF coils with complex or irregular 3D structures through these techniques, especially given the demands of miniaturization. Therefore, the researchers sought to overcome these issues through their experiments with 3D printing.

While performance may remain inferior to commercial probes for now, the study proved the 3D printed probe heads were able to meet the requirements of the team’s customized MR experiments. In light of this, the proposed method presents a basis for customized probe heads for NMR studies and clinical MRI detection, and has opened up a new class of applications in MR systems for 3D printed components.

Further details of the study can be found in the article titled “3D-printed integrative probeheads for magnetic resonance”, published in the Nature journal. The study was co-authored by J. Xie, X. You, Y. Huang, Z. Ni, X. Wang, X. Li, C. Yang, D. Zhang, H. Chen, H. Sun, and Z. Chen.

3D printing electronics

Despite the relative infancy of 3D printing electronics compared to other additive manufacturing applications, new technologies are being continually developed in this space while the potential applications are ever-expanding.

At the forefront of this area is Nano Dimension, an Israeli 3D printing electronics firm. In September 2019, the company announced it was developing 3D printed capacitors using its DragonFly electronics additive manufacturing system. Shortly after, Nano Dimension announced a multi-year agreement with South Korean technology innovation hub Chungbuk Technopark (CBTP), with the firms developing a fully functional, 3D printed IoT communication device for their first partnered product.

More recently, the firm teamed up with military sensor specialist HENSOLDT to successfully print and assemble a double-sided layer printed circuit board (PCB), bringing the development of 3D printed high-performance electronic components one step closer.

Elsewhere, Silicon Valley-based startup Space Foundry is looking to introduce plasma 3D printing into the electronics industry, while researchers from the University of California Los Angeles (UCLA) have devised a way of producing 3D printed electronics nearly five times faster than conventional techniques. In February, high-precision micro dispenser manufacturer nScrypt succeeded in microdispensing consistent 50-micron solder and adhesive dots for 3D printed electronics, which could pave the way for solder dots to be printed directly and precisely onto flat and irregularly-shaped electronics boards.

Most recently, 3D printer manufacturer Azul 3D partnered with electronics firm DuPont to introduce “next-generation 3D printing technologies” into the electronic materials industry, researchers from MIT’s Computer Science and Artificial Intelligence Laboratory developed a novel 3D design environment dubbed ‘MorphSensor’ to allow custom parts to be designed for 3D printing with both electronic viability and mechanical functionality in mind, and German electronic 3D printing company Neotech AMT embarked upon a joint project with the University of Hamburg to develop an AI-driven Quality Assurance system for 3D printed electronics.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printing and manufacturing procedure of integrative MR probeheads for different scenarios. Image via Xiamen University/Nature.