Space Foundry is a Silicon Valley-based startup looking to introduce plasma 3D printing in the space and electronics industries.

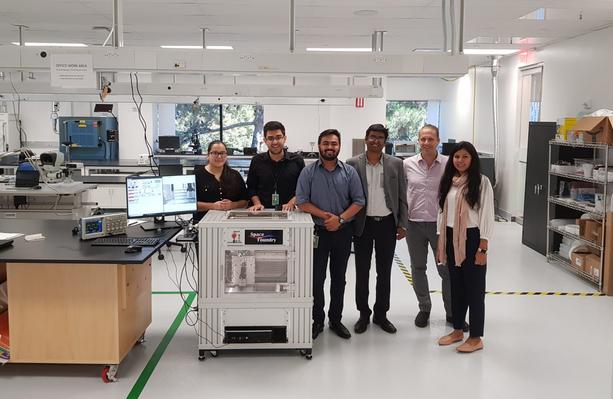

The brainchild of PhD researcher Ram Prasad Gandhiraman and Stanford University scientist Dennis Nordlund, Space Foundry has developed a direct write printing technology allowing for multi-material printing and tailored material characteristics.

Using plasma users are able to 3D print on a number of surfaces, including glass. This has significant benefits with applications in space missions, as well as the development of electronics devices with Internet of Things (IoT) capabilities. Costing over $100,000, the printer is said to have been sold to at least six customers so far. Space Foundry has also received a $2.5 million grant from NASA for its work.

Highlighting the potential of his company’s approach, Nordlund says:

“Imagine tomorrow, the head-up display need not exist in a car; the windshield can be a device beaming information. The world has endless possibilities with this new form of printing.”

Plasma 3D printing in space

Space Foundry was borne out of a friendship between Gandhiraman and Nordlund over a mutual interest in material sciences and space missions. The two initially came in contact with one another while workng at Stanford. Operating in Nordlund’s garage, they developed the plasma printer after three years of work, after which they founded Space Foundry in 2017.

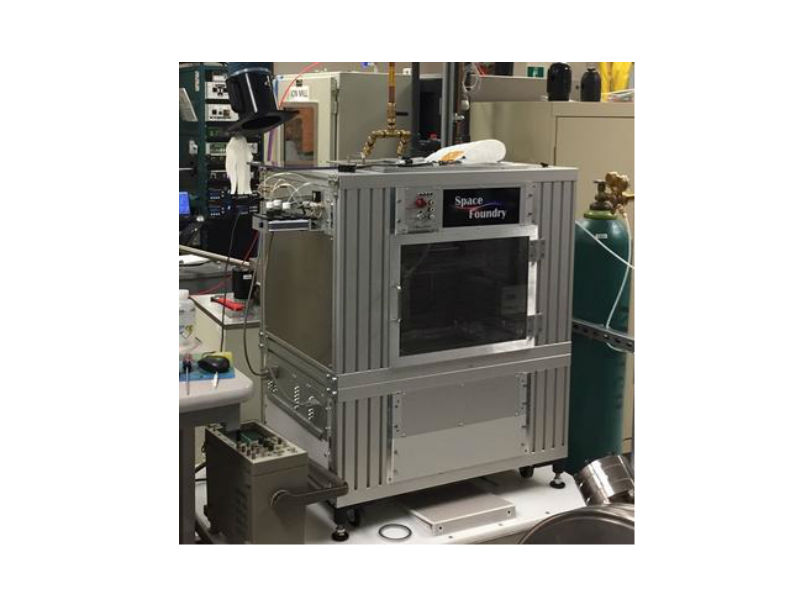

With its multi-material 3D printing capabilities, Space Foundry’s plasma printer can be tailored to a wide range of materials. The machine uses a patent-protected print head with an integrated fluid delivery system, allowing for a combination of multiple liquid precursors and gas mixtures.

Plasma printing operates by forming cavities in a print surface, in which plasma is then able to develop. Afterwards, various materials like polymers, glass and silicon can be impressed onto the substrate. Surfaces with any geometries such as arrays of spots, or with targeted chemical functionalization, can be produced with the plasma printing process.

This can prove useful for producing glass-based circuit boards for IoT devices and Industry 4.0. Space Foundry believes that its technology can have a significant impact in the production of smart devices and printed electronics: “Space Foundry aims to disrupt the printed electronics equipment industry and expects to have launched a product that will outperform conventional technologies and have established a strong market position and recognized brand,” the company’s website states.

The plasma printer’s ability to print on any surface is also particularly applicable in the zero gravity conditions of space, where many 3D printers are not able to operate. NASA itself is one of the six customers who have purchased Space Foundry’s system. The company is currently selling standalone printers, however it plans to offer contract development services in late 2020.

Plasma in 3D printing

Although plasma printing is yet to be commercialized, plasma has been used alongside 3D printing with beneficial results, particularly in attaching parts together. For example, Creabis, a Kirchheim-based 3D printing service bureau, uses Relyon Plasma’s piezobrush PZ2, a handheld cold plasma device, to bond 3D printed parts. With a strong bond between assembled 3D printed parts, it is possible to manufacture large-sized sturdy components on small sized 3D printers.

Plasma treatments have also been used before to improve the quality of 3D printing materials such as metal powders.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows purple and pink plasma ball. Photo via Hal Gatewood on Unsplash.