Israeli 3D printed electronics company Nano Dimension has announced the development of 3D printed capacitors manufactured using its DragonFly electronics additive manufacturing system.

The capacitors are embedded within the layers of the company’s 3D printed circuit boards (PCBs), meaning they can both be 3D printed in one job, therefore saving space and eliminating the need for assembly. Nano Dimension performed extensive testing around the 3D printed capacitors to ensure repeatability of the component with the DragonFly system.

“The test results clearly show that with the DragonFly system our customers can achieve repeatability comparable to that of traditional processes in short-run manufacturing of capacitors using 3D printing,” commented Amit Dror, CEO of Nano Dimension.

“Along with high accuracy, miniaturization and space saving on the board, these are key factors in the electronics production process and next generation electronics applications.”

3D printed electronics

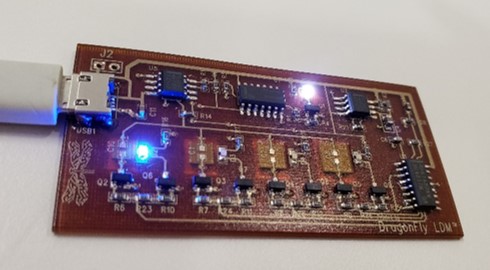

Nano Dimension’s DragonFly 3D printer is capable of producing customized PCBs on-demand. With several iterations of the system, the company recently launched the DragonFly LDM (Lights-Out Digital Manufacturing), a DragonFly Pro upgrade. In an interview, Amit Dror told 3D Printing Industry “The DragonFly LDM is the next evolutionary step in the DragonFly chain.”

Starting out with systems that can 3D print multilayer PCBs, Nano Dimension has since expanded its technology, introducing the fabrication of antennas, capacitors, and “just recently” Dror added, “transformers.” In February 2019, the company was granted a patent for its dielectric ink used to manufacture its 3D printing electronics.

Manufacturers and organizations are exploring the potential of 3D printed PCBs using Nano Dimension’s technology in order to reduce the number of steps typically needed to make PCBs, and open up new possibilities in electronics. The DragonFly printer has been used in many such applications including radio frequency (RF) space systems, IoT communication devices for smart homes, and sensor technologies.

Saving space on 3D printed PCBs

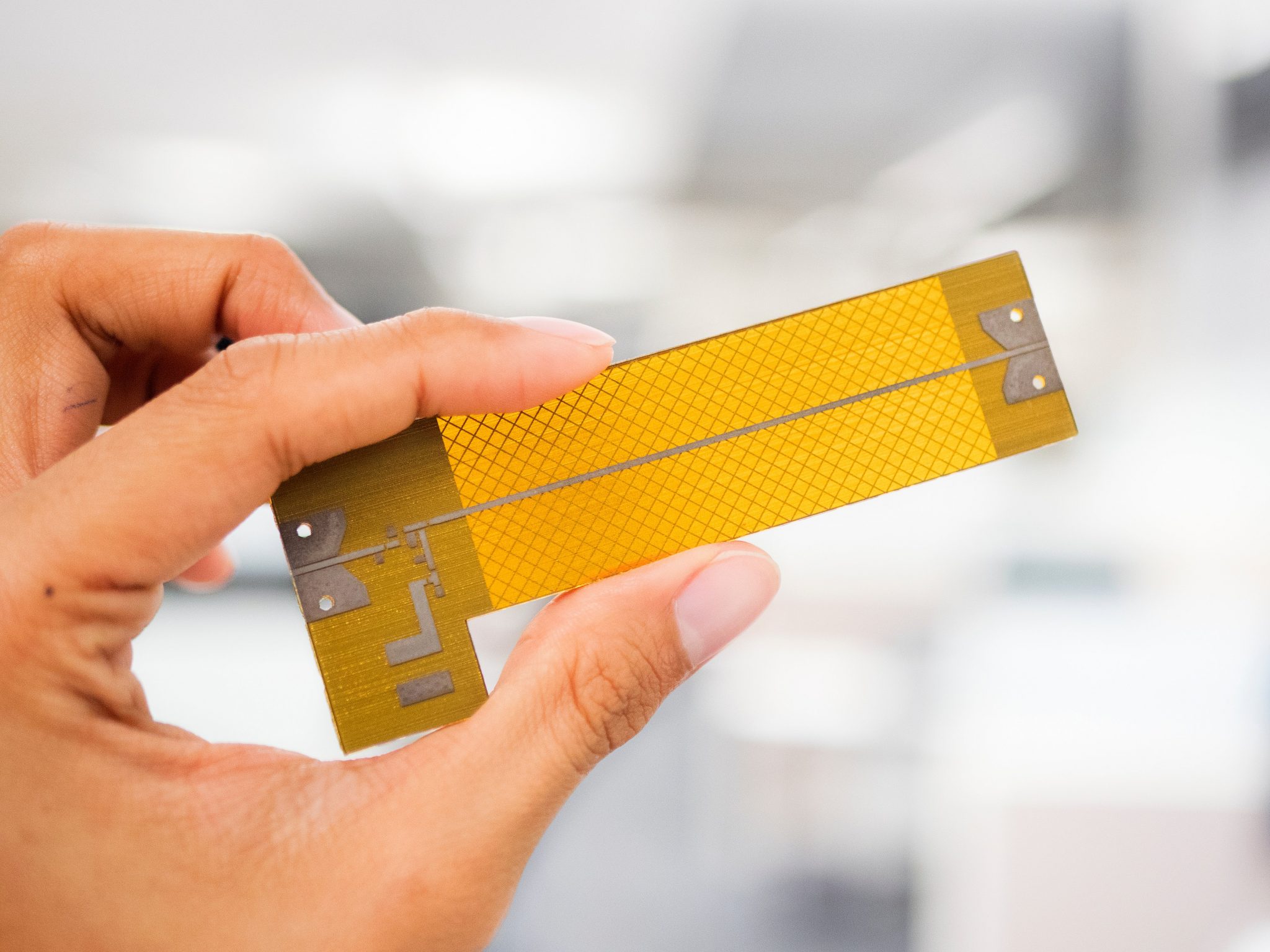

Capacitors are devices used in electronic circuits to store energy and electric charge. They comprise one or more pairs of conductors separated by an insulator. Often, they are used in electronic filters to keep out unwanted frequencies and noise for a range of applications, helping to stabilize power supply and keep a steady voltage in the process. Nano Dimension states that its capacitors can be used in radio-frequency transmission lines, audio processing, radio reception, and power circuit conditioning.

The company tested capacitors with different 3D dimensions, with each reportedly demonstrating consistent results with statistically validated data. Repeatability tests of the 3D printed capacitors showed less than 1 percent variance between the components. The results are based on over 260 tests with 30 different 3D printed capacitor dimensions.

Nano Dimension manufactured the capacitors using the same dielectric and metal inks implemented to create its 3D printed PCBs, therefore enabling the integration of the two parts in one print job on the DragonFly system. This allows electronics engineers and manufacturers to avoid a potentially time-consuming and complex assembly process, reducing the overall lead time of traditional production techniques.

3D printing the capacitors within the inner layers of the PCBs also saves space on the surface of the circuit board. Nano Dimension claims that the reduced footprint falls in line with industry trends towards miniaturization and flatness of electronic devices for consumer, industrial and military applications. The extra space facilitates the inclusion of further functional components on the surface board, while also allowing designers to shrink the component size.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows graphic showing the multiple layers of a 3D printed circuit board. Image via Nano Dimension on YouTube.