Designed for 24 hour electronics production, the DragonFly LDM (standing for Lights-Out Digital Manufacturing) is a new 3D printer and DragonFly Pro upgrade from Israeli 3D printed electronics company Nano Dimension. Hinted at in a corporate update earlier this month, the machine was launched today through the company’s global sales channel and requires minimal operator intervention, representing a significant advance for 3D printed electronics.

“The DragonFly LDM is the next evolutionary step in the DragonFly chain,” Amit Dror, Nano Dimension CEO and co-founder, told 3D Printing Industry in a press briefing ahead of the announcement. Starting out with systems that can 3D print multilayer PCBs, Nano Dimension has since expanded its technology, introducing the fabrication of capacitors, antennas, and “just recently” Dror added, “transformers.” However, Dror continued “What we learnt over the last 18 months is that customers want more.”

“How do you get a list of applications that goes far and beyond PCB prototyping?”

Supported by inventory and rigorous internal and third-party testing, the DragonFly LDM is Nano Dimension’s answer to customers seeking to bring the unique benefits of 3D printing to electronics manufacturing.

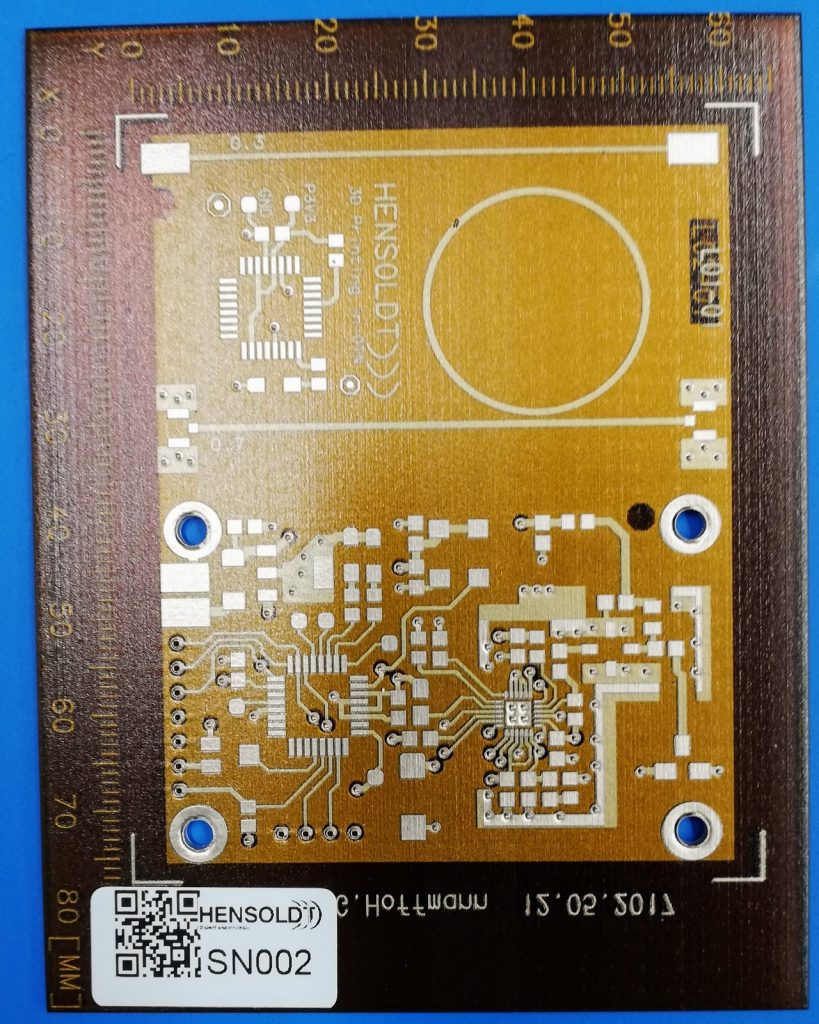

Collaboration with HENSOLDT

Through authorized Nano Dimension reseller Phytec New Dimensions, German sensor and defense electronics provider HENSOLDT became the first customer of the DragonFly LDM about a month ago. An experienced user of its predecessor, the DragonFly Pro, HENSOLDT was well equipped to test the new improved system, and compare it to prior production capabilities.

For the LDM campaign, HENDSOLDT provided Nano Dimension a series of reference circuits which could be used to compare its throughput to that of the DragonFly Pro. In a like for like comparison, the DragonFly LDM proved capable of achieving printing times above 40% higher than those possible on the Pro.

Following third-party trial Andreas Salomon, 3D printed electronics Project Lead at HENSOLDT, commented that the DragonFLy LDM “will be a great addition for Hensoldt, enabling us to develop innovative applications faster and with far better machine availability and lower maintenance than ever before.”

Reducing machine downtime

Key to enabling the DragonFly LDM’s increased productivity are a number of system updates that have been made to cut machine downtime and maintenance requirements.

An on-board camera has been added to improve droplet calibration between multiple materials. Before, for optimal operation of its 3D printers, Nano Dimension requested that this calibration be done at least once per week resulting in up to 6 hours of machine downtime. By being able to monitor calibration in real time, the uptime is now significantly increased. Additional sensors have also been added to the machine for monitoring parameters like humidity, temperature and material.

Even more crucially, the DragonFly LDM has an automated no-contact printhead washing module. Absent from preceding DragonFly 3D printers, the LDM’s self-cleaning system is operated by algorithms, and washes its inkjet heads every few hours. Not only does this cut down on manual maintenance of the machine, it also helps to ensure the quality and consistency of prints.

Though not quite yet at the stage where all 3D printed objects are automatically removed from the print bed with the replacement of a new plate, the DragonFly LDM is enabling 24/7 production of low volumes from 10s – 1000s of pieces per week (dependent on size).

DragonFly LDM technical specifications

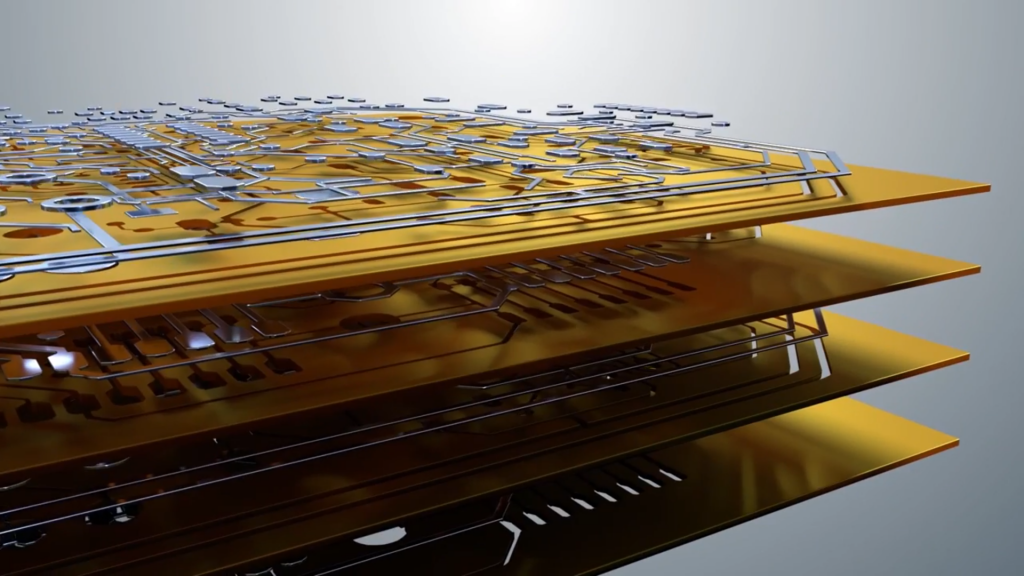

Like the DragonFly Pro, the DragonFly LDM has a build volume of 160mm x 160mm x 3mm. It uses Nano Dimension’s proprietary piezo drop on demand inkjet technology, and it contains two print heads – one for depositing silver nano particles, and the other for dielectric inks. It is capable of 3D printing a minimum layer thickness of 17μm, or, with dielectric materials, a minimum thickness of 35μm, with a mechanical accuracy of 0.001 mm. Operating temperature of the systems is 64°F (18°C) to 72°F (22°C), at 35% – 55% humidity.

All of Nano Dimension’s DragonFly Pro customers (around 40 worldwide) will be eligible for upgrade to the DragonFly LDM, but the system is also available as a standalone machine.

Concluding the system’s announcement in a public press release, Dror said, “We’re confident that the LDM system will provide best in class additive manufacturing of printed electronics on the market, making it possible for companies to be more innovative, improve productivity and reliability, lower costs and reduce time-to-market.”

For all of the latest 3D printer releases subscribe to our newsletter, follow us on Twitter, and like us on Facebook. Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the DragonFly LDM 3D printer. Photo via Nano Dimension