3D Systems has been in the news regularly again this week following the company’s 2012 results being released and completion of the Geomagic acquisition. On the technology front, 3D Systems has also announced the immediate availability of eight new ProJet 3500 professional 3D printers all of which, the company claims, deliver greater productivity and are equipped with its latest remote tablet controls.

Following the launch of the first two ProJet systems at Euromold back in December of last year — the ProJet 3500 HDMax and the ProJet CPXMax — this latest announcement brings the total number of Projet Systems to 10. The ProJet 3D printers are all based on the same platform which utilises 3D Systems’ Multi-Jet Modeling (MJM) print technology, a production-grade print head, advanced material management, tablet-like touchscreen controls and remote tablet and smartphone connectivity. However, I was intrigued by the fact that the company introduced eight new models in one go; and, because the press release was a little vague on the specifics I asked for more details on the differentiators.

As ever, Cathy Lewis, 3D Systems’ Marketing Director, was keen to facilitate and proffered the following information on the eight new printers:

ProJet 3500 series printers are compatible with 3D Systems’ existing VisiJet print materials.

ProJet 3510 SD (Standard Definition): This is the entry level 3D printer in the 3500 series, it is affordable but still prints high quality, durable plastic parts for engineering and mechanical design applications including functional testing, form and fit verification, rapid prototyping, design communication, rapid tooling and more.

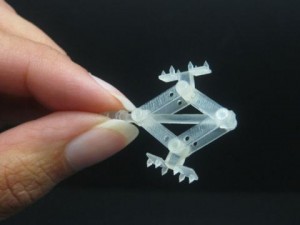

The ProJet 3510 CP is transforming the use of 3D printing for the rapid production of direct investment casting patterns for virtually any geometry. This 3D printer mass produces 100% Real WaxT patterns with smooth surfaces quality and exceptional precision, supporting almost unlimited applications.

The ProJet 3510 DP is a Dental Professional 3D Printer that accurately, consistently and economically manufactures precision wax-ups for dental labs.

Lab technicians can scan a model, design a virtual wax-up using 3D software, and send the resulting data to the ProJet 3510 DP to print.

Buddy Byrum, Vice President of Product & Channel Management for 3D Systems concluded: “With the addition of these new printers we’ve expanded our best-ever capabilities across a new ProJet 3500 family of ten printers. These new printers produce feature detail and quality that is unrivalled, and deliver unparalleled user experience including on-the-go access through our innovative and exclusive Print3D App for tablet computers and smartphones.”

Source: 3D Systems