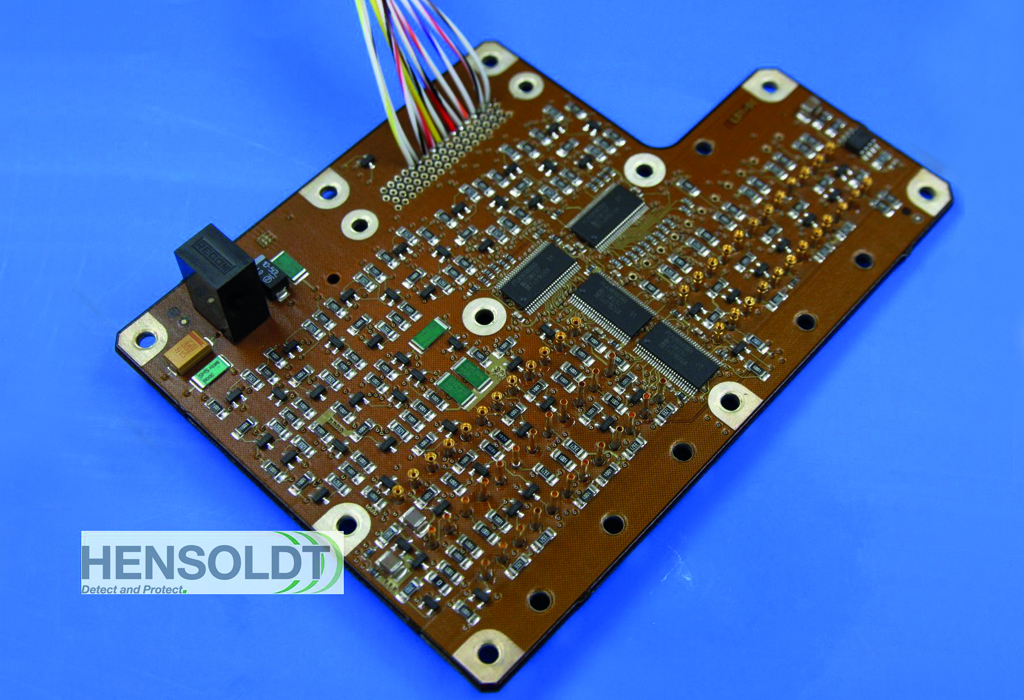

Military sensor specialist HENSOLDT and leading AM electronics provider Nano Dimension have announced the successful 3D printing and assembly of a double-sided ten layer PCB (printed circuit board). The “major breakthrough” is a step toward developing high-performance electronic components through additive means. HENSOLDT hopes to develop the work further and apply the technology to military applications such as radar and optronics.

Thomas Müller, CEO at HENSOLDT, explains: “Military sensor solutions require performance and reliability levels far above those of commercial components. To have high-density components quickly available with reduced effort by means of 3D printing gives us a competitive edge in the development process of such high-end electronic systems.”

3D printed circuit boards

Additively manufactured electronics are useful for verifying the functionality of a newly designed electronic component before it is mass-produced. The agile and customizable nature of AM makes it perfect for prototyping previously untested electronic circuitry. The result is a significant reduction in production time and costs, as well as a higher quality end product due to pre-production verification.

Fabrication of the PCB utilized a new dielectric polymer ink and conductive ink developed by Nano Dimension. According to HENSOLDT, to date, 3D printed PCBs have not been strong enough to survive the soldering process necessary to create a double-sided circuit board. Therefore, the high-performance electronic structures soldered to both sides make the ten layer PCB a “world-first”.

Yoav Stern, Nano Dimension’s President, and CEO, added: “Nano Dimension’s relationship with HENSOLDT is the type of partnership with customers we are striving for. Working together and learning from HENSOLDT led us to reach a first-of-its-kind in-depth knowledge of polymer materials applications. Additionally, it guided us in the development of Hi-PEDs (High Performance Electronic Device) that create competitive edges by enabling unique implementations with shortest time to market.”

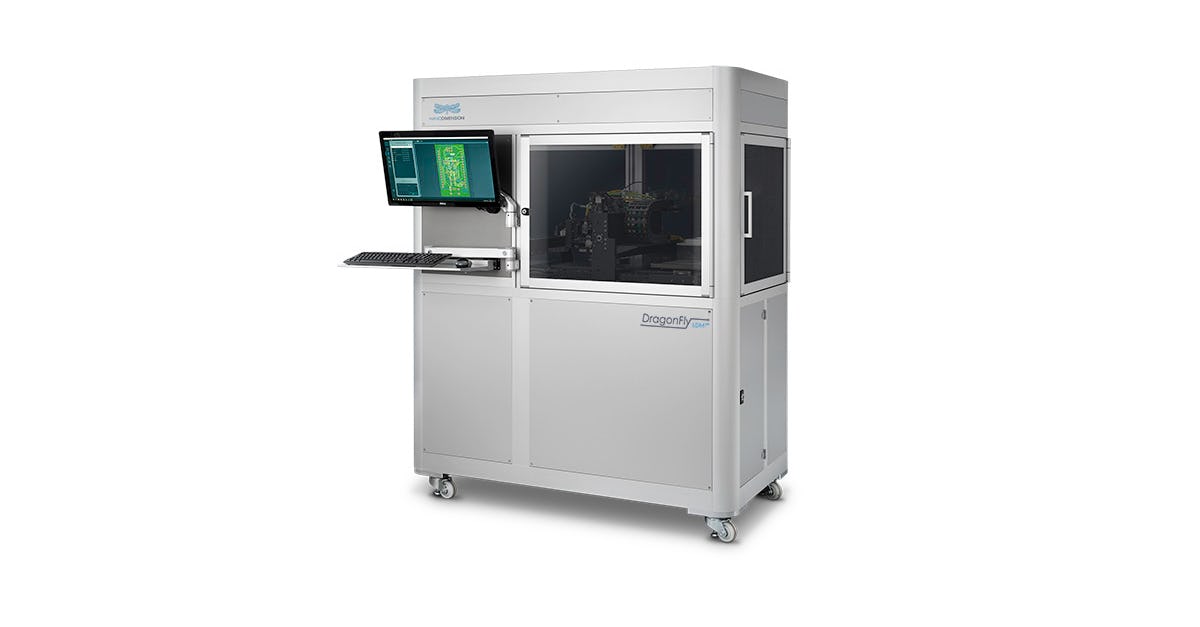

Having started working with Nano Dimension’s DragonFly 3D printing system in 2016, HENSOLDT graduated to implementing the DragonFly LDM system last year and has been working with it ever since. Earlier this year, leading polymer manufacturer REHAU also announced an electronics breakthrough with the 3D printing of an electronic touch sensor using the DragonFly LDM. By integrating an AM electronic circuit, REHAU was able to functionalize one of the Nanodimension premium polymer materials, paving the way for “smart polymers” in the coming years. Elsewhere, at UCLA, major strides are being made by researchers who have developed a new highly efficient method of 3D printing electronics. The new approach was determined to be nearly five times faster than conventional techniques.

In response to the announcement, the share price of Nano Dimension tripled in value. Moving from $0.77 to $3.28.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed ten layer circuit board. Photo via HENSOLDT.