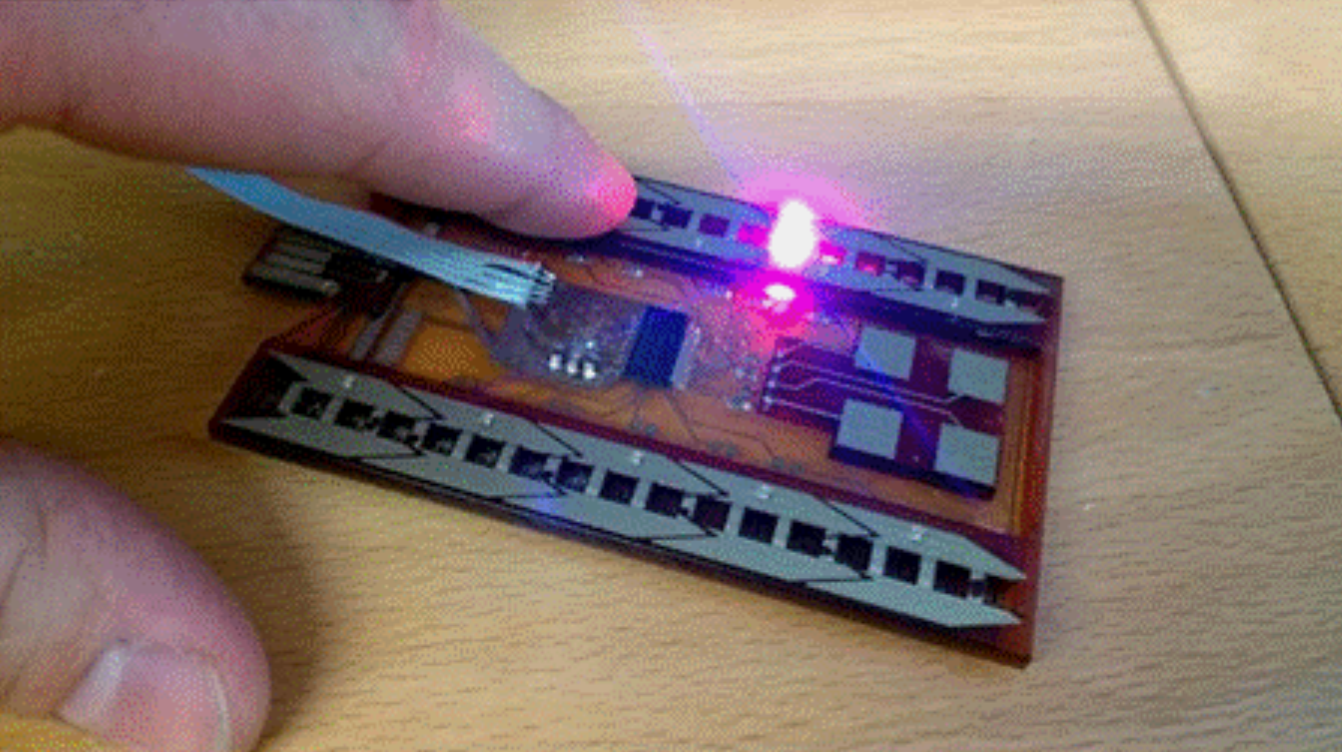

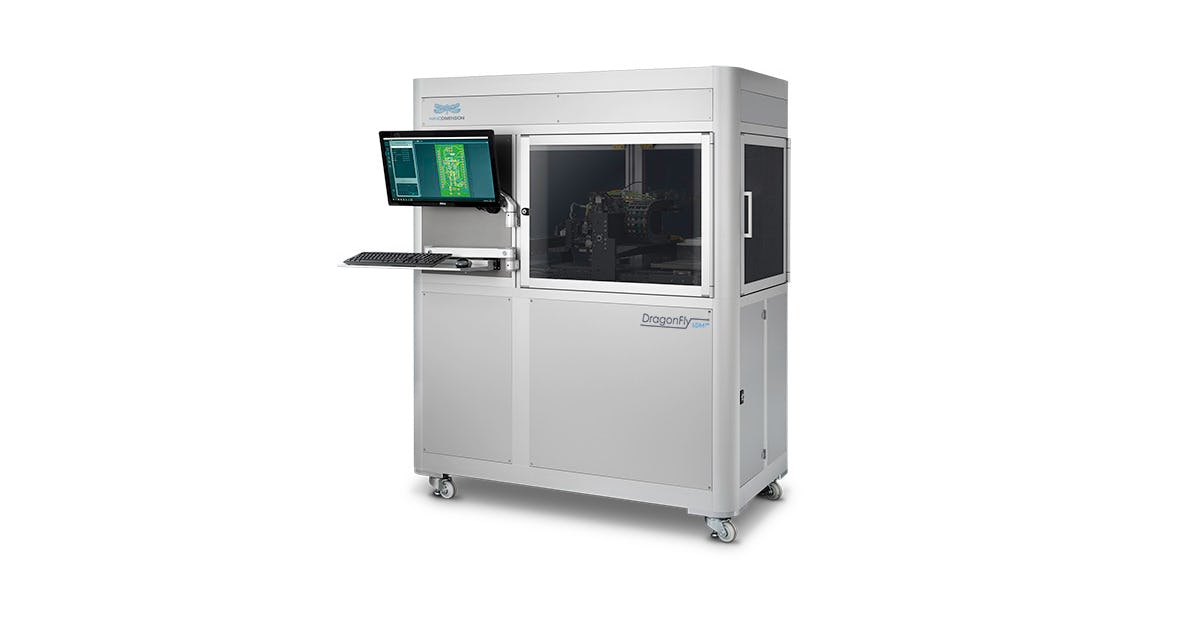

Nano Dimension, a specialist in AM electronics, and REHAU, a leading polymer manufacturer, have announced the successful 3D printing of a 3D touch sensor. Using Nano Dimension’s specialized DragonFly LDM (Lights-out Digital Manufacturing) 3D printer, REHAU was able to functionalize one of its premium polymer materials via the integration of an AM electronic circuit.

Yoav Stern, President and CEO of Nano Dimension, stated: “REHAU will be the first of its kind to bring together in-depth knowledge of polymer materials processing with the ability to insert electronics.”

Valentin Storz, General Manager of Nano Dimension EMEA, added: “This gives REHAU the increased design freedom to develop innovative products, quickly and cost effectively.”

Electronics into Polymers

The touch sensor was developed as part of REHAU’s ‘Electronics into Polymers’ program, which aims to add value to REHAU’s polymer materials by integrating electronics into them – making them “smarter”. In the case of the “sleek design” touch sensor, REHAU’s customers can now make use of a back-lit human-machine-interface surface for a number of innovative applications. According to REHAU, the program is simply the company’s way of developing functional devices with improved performances, efficiencies, and lower costs from its premium polymers. This comes in an age where smart home, smart mobility, and the Internet of Things reign supreme so the polymer industry may need to adapt to keep up.

Dr. Ansgar Niehoff, Head of ‘Electronics into Polymers’ at REHAU, stated: “Smartification is no longer just a vision for us. REHAU is developing improved products for the smart home and IoT environment, and Nano Dimension is providing important technology to help accelerate the availability of promising new applications.”

Dr. Philipp Luchscheider, a REHAU engineer who worked on designing the 3D touch sensor, added: “With the DragonFly LDM we will drive forward REHAU’s electronics into polymers strategy to speed up in-house electronics development and find new installation spaces and functions for our products.”

DragonFly LDM 3D printer

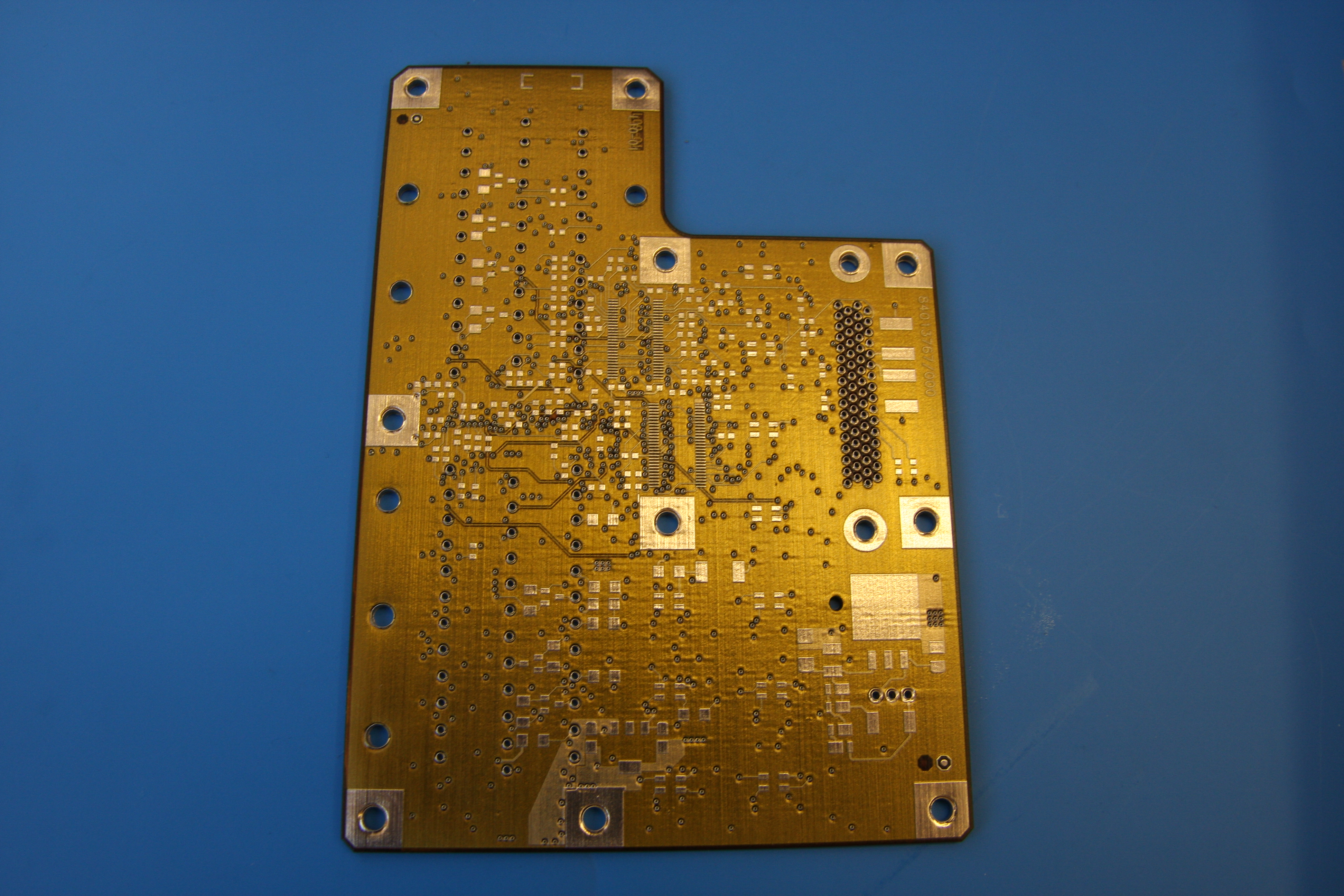

Released last year, the DragonFly LDM features Nano Dimension’s established PCB 3D printing technology, as well as 24/7 “lights-out” automated manufacturing capabilities. The system’s unique and non-standard shape printing abilities mean it can be used to additively manufacture multilayer PCBs, capacitors, coils, sensors, and antennas. The machine also sports a self-cleaning printhead and an in-situ material monitoring sensor.

The 3D printing of electronics is one of the sub-fields of additive manufacturing that is truly in its infancy. Earlier this year, high-precision micro dispenser manufacturer nScrypt announced that it had successfully 3D printed 50 micron solder and adhesive dots for electronics boards. The company used its SmartPump conical pen tip to precisely control the volume of material deposited, releasing the details of the project in a research paper on its website. Elsewhere, at UCLA, researchers have developed a highly efficient method of 3D printing electronics. The new approach was determined to be nearly five times faster than conventional techniques.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed touch sensor. Photo via Nano Dimension.