Solid-state metal 3D printing specialist Fabrisonic has leveraged Powder Bed Fusion (PBF) to create fine organic patterns that can be embedded into large structures through its patented Ultrasonic Additive Manufacturing (UAM) process.

Combining the strengths of these two processes enabled Fabrisonic to create the exact solution needed by a particular customer, who required a part with organic stainless steel geometry, dissimilar metal transition, and embedded sensors that are fully encapsulated in the metal.

Fabrisonic’s UAM technology

Fabrisonic’s UAM additive manufacturing technique is a hybrid metal 3D printing process that constructs objects through ultrasonically welding dissimilar metals together via sound vibrations. The technology operates at a low temperature to enable dissimilar materials such as electronics to be embedded into metal alloy structures.

Fabrisonic patented its UAM 3D printing method in 2017, and later released its SonicLayer 1200 machine which incorporated the technology. Since then, Fabrisonic has partnered with EWI and Luna Innovations to build a Smart Baseplate for Laser Powder Bed Fusion (LPBF) additive manufacturing processes. The baseplate was 3D printed with embedded sensors in order to properly measure the loads passing through it.

At the tail end of 2019, the firm again collaborated with Luna Innovations for a 3D printed sensor project for NASA. Through its UAM technology, Fabrisonic was able to 3D print sensors directly into the wall of an existing NASA cryogenic fuel pipe.

The company’s most recent development involved working as part of a NASA SBIR study to successfully merge different amorphous alloys into multi-metal cladding through UAM. The method was able to join the metals to crystalline substrates without destroying their beneficial properties, making them well-suited for future potential cladding applications in the aerospace sector.

Combining UAM and PBF

PBF involves depositing a layer of metal powder over a build plate, upon which a laser melts a cross-section out of the powder before new powder is deposited, and the process repeated.

While UAM is well suited to printing large components with multiple metals, embedded sensors, and internal structures, it is not the best choice for creating fine, organic structures. This is where PBF comes in. Fabrisonic utilized PBF to create delicate organic patterns which it could then embed into large structures through UAM.

To create the base structure for the PBF process, Fabrisonic partnered with EWI, with the PBF components arriving at the company as rough blanks. These were then placed in a fixture to constrain the part for welding, so that the vibrations caused by the UAM process wouldn’t move the part out of position. The top of the part was then milled to a flat, even surface.

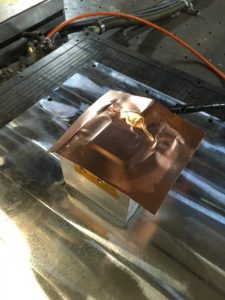

Aluminum and copper sheet layers were printed one-by-one onto the top surface, the point at which the combining of dissimilar metals took place. The part was then milled to create a pocket for the custom sensor, in which it was placed before UAM was employed to add additional layers of copper and aluminum. This ensures the sensor is protected by a hermetic seal formed by the additional layers bonding to the surrounding metal. In addition to prolonging the life of the sensor, the seal also improves the accuracy of the sensor’s readings.

According to Fabrisonic, its engineers and designers are looking forward to future opportunities to combine the benefits of other forms of additive manufacturing with the benefits of its UAM method.

Caption: Layers of aluminum and copper sheet were then printed layer-by-layer onto the top surface. Image via Fabrisonic.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows finished part made through combining Ultrasonic Additive Manufacturing and Powder Bed Fusion. Image via Fabrisonic.