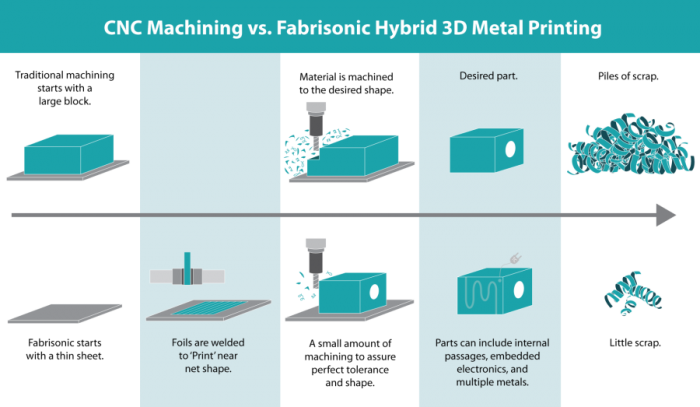

Ohio based metal 3D printing company Fabrisonic has been granted a patent to use its ultrasonic additive manufacturing in a hybrid machine with CNC milling.

CEO of Fabrisonic, Mark Norfolk explains the importance of the patent,

By co-locating the welding and milling functions, accuracy can be improved and overall build volume can be increased without increasing machine footprint

What is hybrid manufacturing?

Hybrid manufacturing provides the advantages of 3D printing to create complex geometrical parts alongside the ability of other manufacturing methods such as CNC machine to ensure high tolerance and strength. There are several companies that create machines combining manufacturing techniques. For example, DMG MORI who have acquired a controlling stake in SLM manufacturers REALIZER.

Ultrasonic Additive Manufacturing

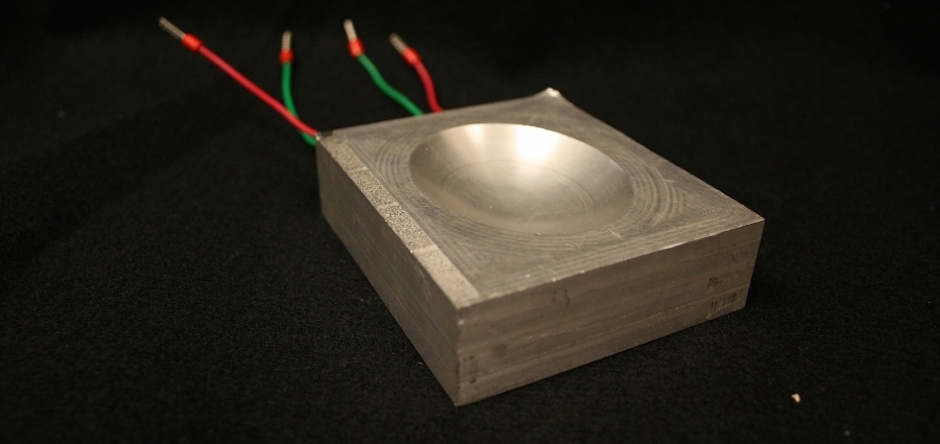

Fabrisonic’s ultrasonic additive manufacturing technology uses sound vibrations to merge layers of metal foils. This process is novel as it enables welding of dissimilar metals at much lower temperatures. The benefit of this is that it means electronics can be embedded into structures. This would not be possible with other metal 3D printing technologies as traditionally, very high temperatures are required.

Ultrasonic speed

Ultrasonic additive manufacturing also allows for 3D printing at a high-speed. Fabrisonic state that their SonicLayer UAM machines can print “fifteen to thirty cubic inches per hour” opposed to others that, they claim, can only print fractions of a cubic inch per hour. Mark Norfolk believes this patent stakes out Fabrisonic claim as frontrunners in the metal additive manufacturing field. As he says,

Our patents now count 10, which adds confirmation to Fabrisonic’s leadership in developing metal 3D printers.

Other companies approaching hybrid manufacturing machines include Thermwood and Optomec. Thermwood recently added thermographic imagery in order to successfully track 3D printing and control heat management. While Optomec are a large player in the hybrid manufacturing market with their LENS technology. 3D Printing Industry spoke with Optomec for more insight into how they are applying this to large-scale production.

Sign up to our newsletter for the latest 3D printing news. Also, follow us on twitter and Facebook.

Featured image shows Fabrisonic Ultrasonic Additive Manufacturing at IMTS 2016 in Chicago. Photo via Michael Petch.