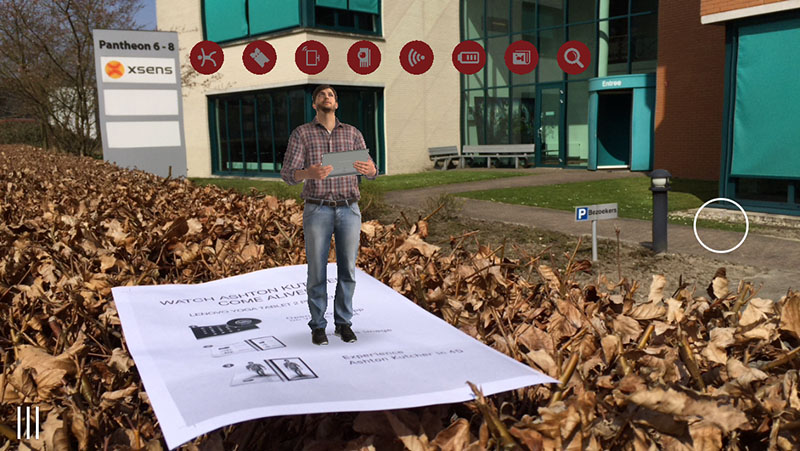

Founded in 2010, DAQRI is a purveyor of augmented reality (AR) technology and based in Los Angeles, CA. DAQRI’s current range of hologram powered products project speedometer and GPS visualizations onto windscreens, and give AR data readings of manufacturing conditions, i.e. pressure, temperature, speed of a machine.

Adding to the general list of surprising celebrity 3D technology investors like footballer Mathieu Flamini, actor Ashton Kutcher has a stake in DAQRI.

In addition to their range Microsoft Hololens type headsets, the company is looking to use holograms to polymerize 3D objects in resin.

3D printing with holograms

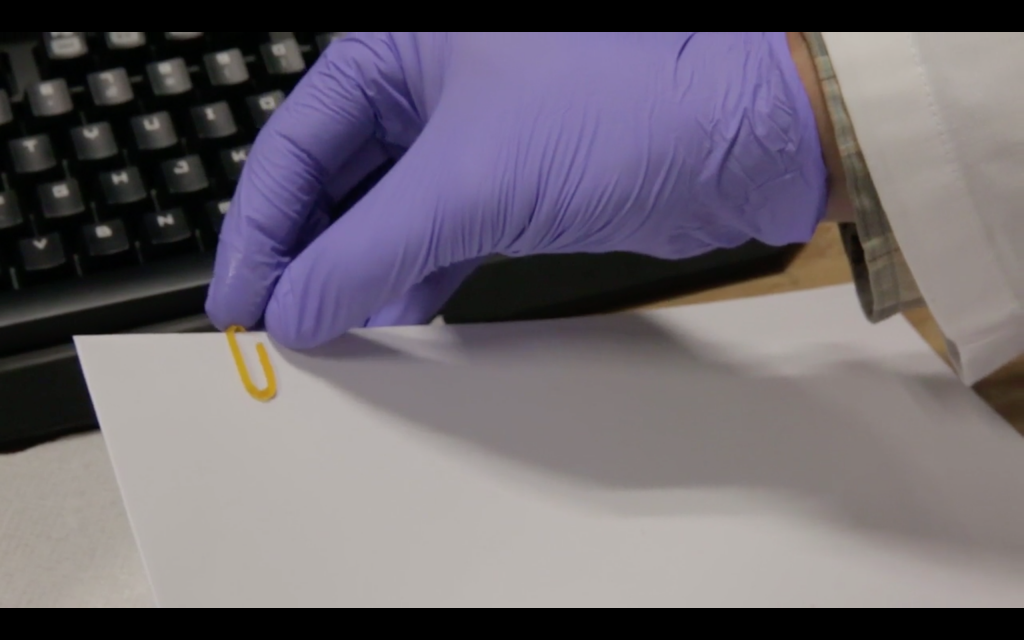

The technology works in a similar manner to standard DLP 3D printer only with lasers in place of a projector. In this conceptual stage, the DAQRI hologram 3D printer is only producing small 3D objects, like paperclips, that have the same geometry throughout.

Enhancing the exposure time on a DLP 3D printer would effectively produce a paperclip in the same amount of time as this hologram approach, but DAQRI’s proposition hopes to be more advanced than that.

Projecting an image of an object in its entirety, instead of in layers, is the key concept that makes this development so interesting from a production point of view. Making objects in layers is the very core of 3D printing’s success, but it is also a hindrance to the speed of 3D prints. Theoretically, hologram 3D printing would be dramatically faster than the current processes. But in order to make it successful, they’re going to need a lot more lasers.

Ideally a hologram 3D printer would beam the image of an object from lasers on both the x and y axis, potentially making an entire grid of beams. Singular beams would not be powerful enough to cure the resin, but combined they would be enough to 3D print an object. Due to the exothermic reaction involved with photo-polymers heat may also be an issue to contend with.

Industry 4.0

Regardless of the methods developed by DAQRI, the technology is going to need a lot of processing power, and enhancing the power of their current headsets is the company’s current goal.

As industry-focused technology, DAQRI’s headsets have the potential to be key parts of the Industry 4.0’s Smart Factories of the future. 3D design company Dassault Systèmes are similarly harnessing enhanced reality technologies, having implemented the HTC Vive into their 3DEXPERIENCE 3D model viewer.

For updates on the latest 3D printing technologies, sign up to the 3D Printing Industry newsletter here. You can also follow us @3Dprintindustry on Twitter, and like us on Facebook.

Featured image shows 3D printing with holograms by DAQRI. All images in this article are courtesy of daqri.com