Fabrisonic is all set to unveil a fourth axis for its SonicLayer line of 3D printers at the upcoming EuroMold 2013 exhibition. SonicLayer incorporates the company’s Ultrasonic Additive Manufacturing (UAM) technology to merge layers of metal. This means SonicLayer users will now be able ‘3D print’ metal to a cylindrical part, enabling cladding and other applications.

In Frankfurt, in December, Fabrisonic will introduce a new module available for its line of UAM SonicLayer 4000 & 7200 machines. The company is performing final construction of a new Sonic Layer 4000R, which has an additional rotary axis designed to position a cylindrical part under the welding system. This new rotary module allows 3D printing of metal features on the outer diameter of a shaft, cylinder or pipe.

The SonicLayer 4000R has a 3-axis CNC mill with bed dimensions of 40” x 24” and a 25HP 8000 RPM spindle for machining any metal part. However, it utilises Fabrisonic’s patented 9kW UAM welding head to additively manufacture solid metal parts. In addition 3D printing metals in a traditional planar approach, the R version allows for welding on a cylinder.

Applications include cladding expensive metals on to inexpensive substrates, adding intermittent stiffeners to pressure vessels and adding 3D features to standard bar stock.

According to Mark Norfolk, Fabrisonic’s CEO: “Ultrasonic additive manufacturing is changing the way that we produce parts. The new rotary module fills a technology gap brought to our attention by many of our current customers.”

Specifications of the SonicLayer 4000R:

- Footprint – X direction: 12’; Y direction: 12’; Height: 113”

- Axis Working Travel – Powered X Axis: ~40”; Powered Y Axis: 24”; Powered Z Axis: 24”

- Linear Accuracy – Positioning: ±0.0002”; Repeatability: 0.0001”

- Table Size – Length x Width: 44” x 24”

- Rotary – 2-8” OD, 12” max part length.

- Welding Machine – US Power: 9 kW; Welding force: 2500 lb, Welding speed (max): 200 ipm

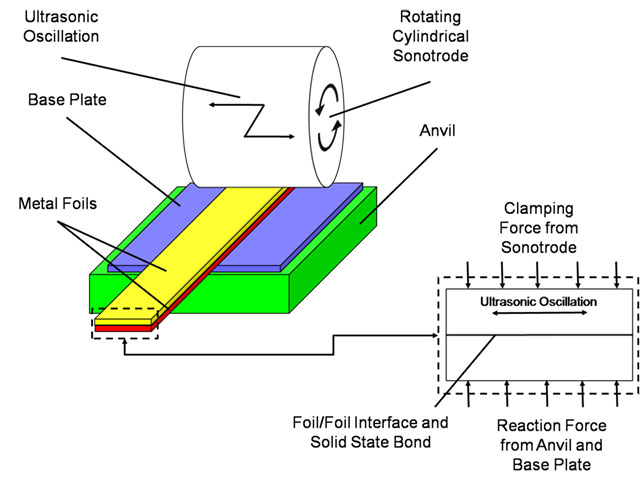

UAM, also called Ultrasonic Consolidation (UC), is an additive manufacturing technique based on ultrasonic welding of metal foils and CNC contour milling. High-frequency ultrasonic vibrations are applied locally to foil metal materials and held together under pressure to create a solid-state weld.

About Fabrisonic:

Fabrisonic, LLC, was founded in 2011 as a joint venture between EWI and Solidica Inc. of Ann Arbor, MI. Since that time, the company has introduced cutting-edge UAM equipment for research, development and full-scale production environments. Fabrisonic is based in Columbus, OH.