From a company whose tagline is “Technology for a 3D Life”, you would expect products related to 3D printing. Until now, Sandretto, a multinational company active in the production of large-sized plastic injection molding machines, produced no such thing, implementing 3D designs in traditional manufacturing.

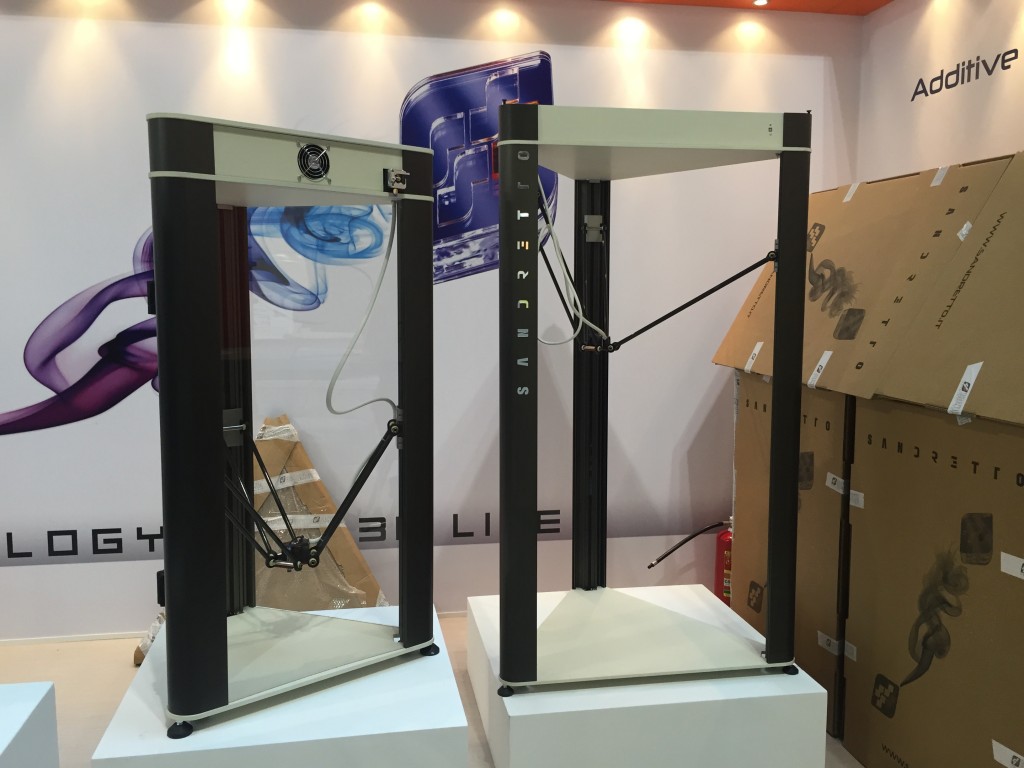

Now, it is finally living up to its self-fulfilling prophecy with a new line of delta 3D printers. The machines’ mechanical toughness and precision can leverage the the strength and know-how of a company with well over 50 years in high-end mechanical molding of plastics.

The new range of delta 3D printers was presented at the PLAST 2015 fair in Milan; however, it is not yet officially on the market. For Sandretto’s new COO of Additive Manufacturing, Roberto Moretti (who, by a strange coincidence has the same last name as Massimo Moretti, WASP’s founder and the first true “prophet” of delta 3D printing in Italy), it is a new challenge. As he explained to EPPM Magazine, he now sees 3D printers coming out of the prototyping offices and making their way into production.

Just like WASP, Sandretto will be offering, primarily, a range of 3 different 3D printers with the smallest one, the SND R250, being just a little bit larger than the DeltaWASP 2040, measuring 25 cm in width and 45 cm in height. It is expected to hit the market at about €2,000. The other two machines are significantly larger: the SND R400 measures 40 x 70 cm, while the SND R700 can 3D print objects as large as 70 cm in width and 120 cm in height.

Sandretto promises that the machines will guarantee extreme reliability, meaning that they do not need to be oiled and can run continuously for 24 hours a day for several days without requiring maintenance. The company also promises that they are going to be fast. The smaller model can extrude up to 35 grams of material per hour, while the largest one goes up to 160 grams of material every hour.

Last, but not least, the machines actually look pretty sleek, with a metal ceramic body covered in carbon fiber, coming both in white and black antracite. Apparently, Sandretto also invested in an internal fablab – the Sandretto Skunk Works Lab – to develop the 3D printer, in order to meet real market demands. In a world where Makers become companies and companies embrace Makers, anything can happen and 3D destinies can be fulfilled.