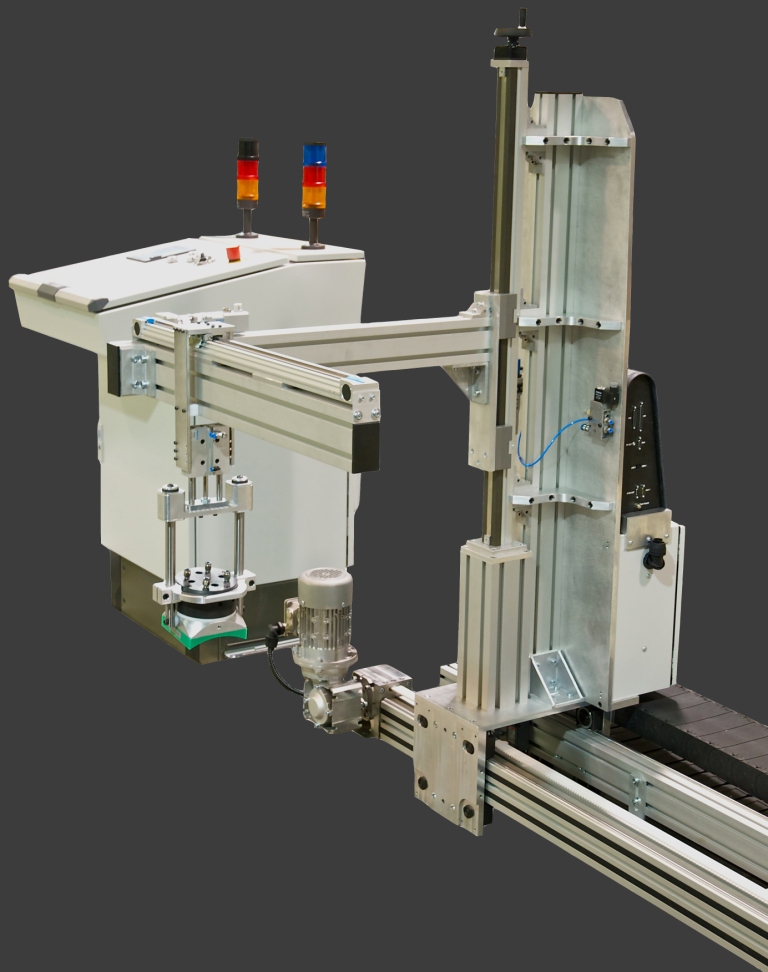

Over on Afinia’s blog Industrial Inspection Systems owner and CEO discusses how rapid prototyping has helped his company become more adaptable to his clients needs, and why they chose Afinia 3D Printers to do it.

3D printing isn’t a new technology to IIS as they adopted it years ago when the only desktop 3D printers on the market were made of laser cut balsa wood. It was immediately a useful tool for their company, and it has been a part of their business ever since. The savings of time and money when using their 3D printers to rapid prototype new products being one of the primary reasons.

“Prior to 3D printing, we had to involve a machine shop to create our system prototypes out of aluminum. With each change and improvement, the costs were adding up so we looked to a less expensive solution.” explains IIS CEO Daniel Lucaci “We found 3D printing to be instrumental to our business, giving us the power to make changes on the fly, quickly and easily,”

They also 3D print custom made cable attachments and electronics enclosures for their clients. The products that IIS sell are not made from over the counter or mass produced components, they are custom made for each individual client for their specific needs. 3D printing allows them to spend less time and money prototyping these custom parts and focus on making them more accurate and durable.

This isn’t a new story of course, rapid prototyping is unarguably the most widely adopted application of 3D printing to date. RP has proven to be an indispensable part of the manufacturing process, and Lucaci’s business is no exception.

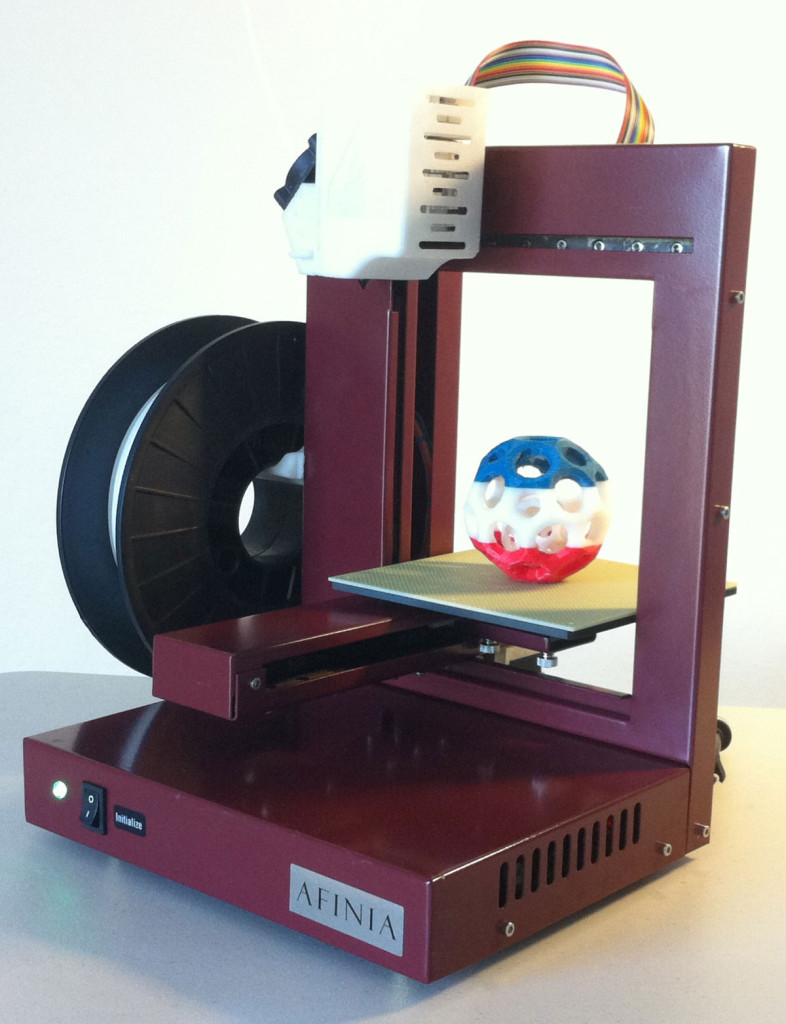

When he first added 3D printing to his business he used a different brand of 3D printer but switched over to Afinia when he discovered that they were rated the best 3D printer on the market by MAKE Magazine, a description that he agrees with. He cites Afinia’s live call support and ease of use as his main motivations. He also curiously cites Afina being a closed source 3D printer manufacturer.

I’m not exactly sure that I agree with his assessment of closed source manufacturers offering better customer support or better standards of production. In fact, I have no idea how the two issues are related really. Still, his is an interesting perspective, and while I may not exactly agree with it Afinia does make what most people in the industry would call fantastic desktop 3D printers and they do offer a level of tech support that most larger companies don’t even try to offer.

While being closed source is certainly working for them for the moment, I do find myself wondering what they’re missing out on by not having a community of dedicated makers pulling their machines apart and trying to make them better. Because let’s face it, being open sourced is less about technological altruism than a lot of open source manufacturers would have you believe and more about inexpensive R&D from the people who actually use their products. Lucaci called open source a double-edged sword and I think that’s very true, but the thing about a double edged sword is, it’s only dangerous if you don’t know how to use it.