While 3D printing manufacturers and professional rapid prototypers gear up for Euromold in Frankfurt, an alternative rich line up of some of the world’s most important 3D printing adopters is getting ready to meet in London for the second annual 3D Printing and Additive Manufacturing Industrial Applications Global Summit.

While last year’s edition focused solely on large 3D printing adopters in the defense, automotive, medical, sporting goods and materials research fields, the 2014 edition will also host Hans Vandezande, Head of Business Development at Materialise one of the world’s leading Additive Manufacturing and Rapid Prototyping services provider and software developer.

The Summit is targeted primarily at decision makers in large companies who want to understand more about the possibilities offered by AM technologies and the cost/benefits of their implementation in a traditional workflow. With over seven years experience at Materialise, Vandezande has acquired extensive experience working with companies to illustrate how to integrate the company’s rapid prototyping and software capabilities to speed up time to market, reduce costs and accelerate product development.

As he explains, 3D printing is currently offering the biggest opportunities in the aerospace sector, with the potential to drastically reduce the weight of aircraft components, and in the medical sector, for the impact it can have on people’s lives. For example, in a recent case, where a walnut-sized heart-model 3D printed by Materialise for an unborn child allowed the surgeons to perform an otherwise impossibly complex operation and save the child’s life.

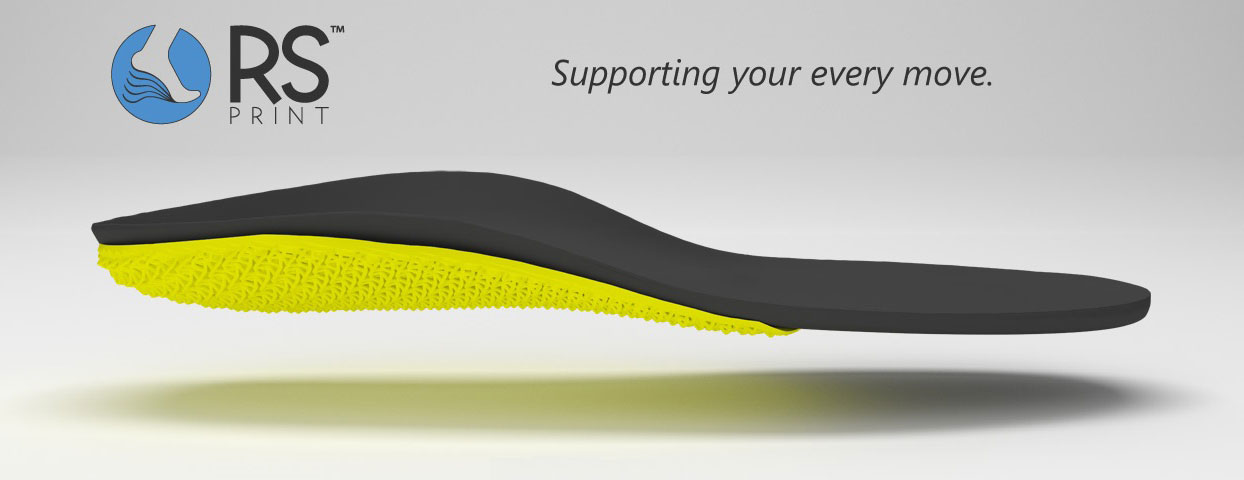

Vandenzande also emphasized Materialise’s consumer applications of the technology, in particular the RS Print Service, which is making it possible for anyone to have a custom made 3D printed insole which in the past was only available to high level athletes. Among other topics, Materialise’s Head of Business Development will be detailing more examples of how 3D printing has provided tangible advantages over traditional techniques and illustrating the most cost competitive applications of AM technologies.

Although it falls alongside Euromold, the line up for the two day conference will offer a wide array of direct experiences from some of the largest global adopters of AM, including representatives from car manufacturer TATA Motors, sports apparel manufacturer HEAD Sports and world leading architectural studio Fosters & Partners.

While 3D printing is rapidly opening up new possibilities for start-ups and lean young companies, it is proving more difficult for some larger and more established groups to understand how to seamlessly make the transition from traditional manufacturing to augmented manufacturing, by introducing new means of production. Even before heading to Euromold to find out about the enormous choice of 3D printers and 3D printing materials available today, anyone interested in implementing these technology should learn exactly how and what to use them for. There is plenty of time to do both — I am!