3D printer manufacturer Formlabs posted a guide for using their stereolithography 3D printer to create parts with screw threads. Obviously plastics and resins are not an optimal material to create threaded screws with, however they have found a few ways to make them work.

The Form 1+ SLA 3D printer is one of the highest resolution desktop 3D printers on the market and as Formlabs evolves their signature printer with new materials they are continuing to push the limits of what you can use it for. In a recent blog post they cover the various options for creating parts with screw threads or incorporating metal parts into 3D printed resin parts.

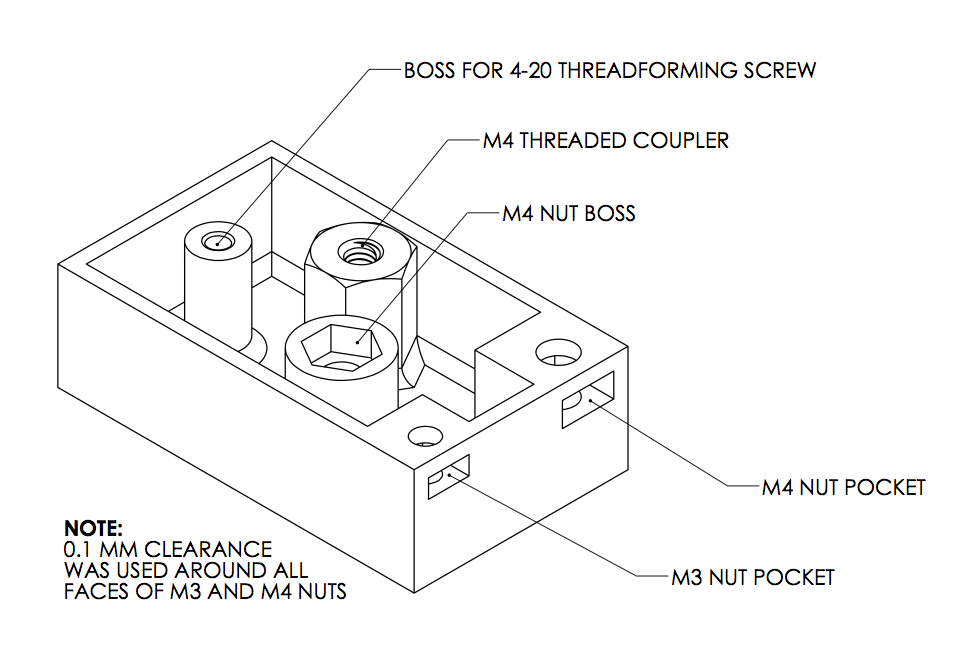

The most effective way to include a screw in a 3D printed part is to leave a pocket for a metal nut. When it comes to screws, metal to metal is always preferable, as a metal screw can easily damage plastic threads, especially if the parts need to be taken apart and assembled more than once. Any metal nut pockets should be designed with a 0.1 offset around the nut, this makes sure it can be forced in and held in place easily with just a small dab of superglue.

The resolution of the Form 1+ can produce working screw threads, however they won’t be especially durable and will be ill suited for reusable fastening. Any small parts can be left out in the sub post-cure for a day or two, the extra light should further cure the resin and make it harder. There is also the option to use thread cutting screws that are made for plastics, however there is a risk of the part cracking or splitting, and as with the 3D printed threads they should not be reused.

If you have a Form 1 or a Form 1+ then you can download a Screw Test Guide that can be printed in resin and will show you all of your available options. You should check out the entire guide over on the Formlabs Blog for more tips and tricks for 3D printing parts with screw threads.