Dutch manufacturer FELIXprinters has announced the release of the FELIX Pro 1, the first in their professional series of FDM 3D printers. The FELIX Pro 1 is the follow up to the FELIX 3.1 which is now part of FELIXprinters’ Premium line of 3D printers and will still receive upgrades and support.

Based on the popular PRUSA i3 design, the FELIX 3.1 was very highly rated among users and the FELIX Pro 1 seems to improve on it in a number of ways. The FELIX Pro 1 comes equipped with dual extruders. The all metal, direct drive hot ends are described as incredibly easy to remove, potentially making maintenance or replacement a breeze. The FELIX Pro 1 has a solid 255 mm X 245 mm X 225 mm build area and is capable of printing at up to .05 mm layer thicknesses. The FELIX Pro 1 uses a variety of 1.75mm filaments, including PLA, PET(g), FLEX, ABS, PVA, WOOD and GLASS.

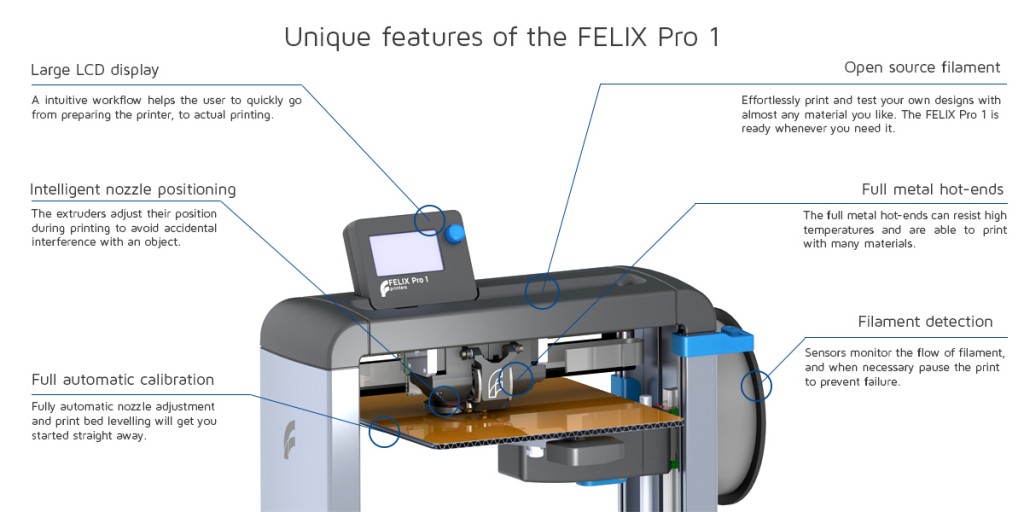

The FELIX Pro 1 includes a number of design features that, together, seem to make a much better user experience. Intelligent nozzle detection increases the distance between the idle nozzle and the print bed, which is a great design feature for a dual nozzle printer. Additionally, the FELIX Pro 1 comes equipped with sensors that can detect when a spool of filament is finished and will pause the print until it is reloaded. The Felix Pro 1 also comes with auto bed leveling and an easily detachable print bed.

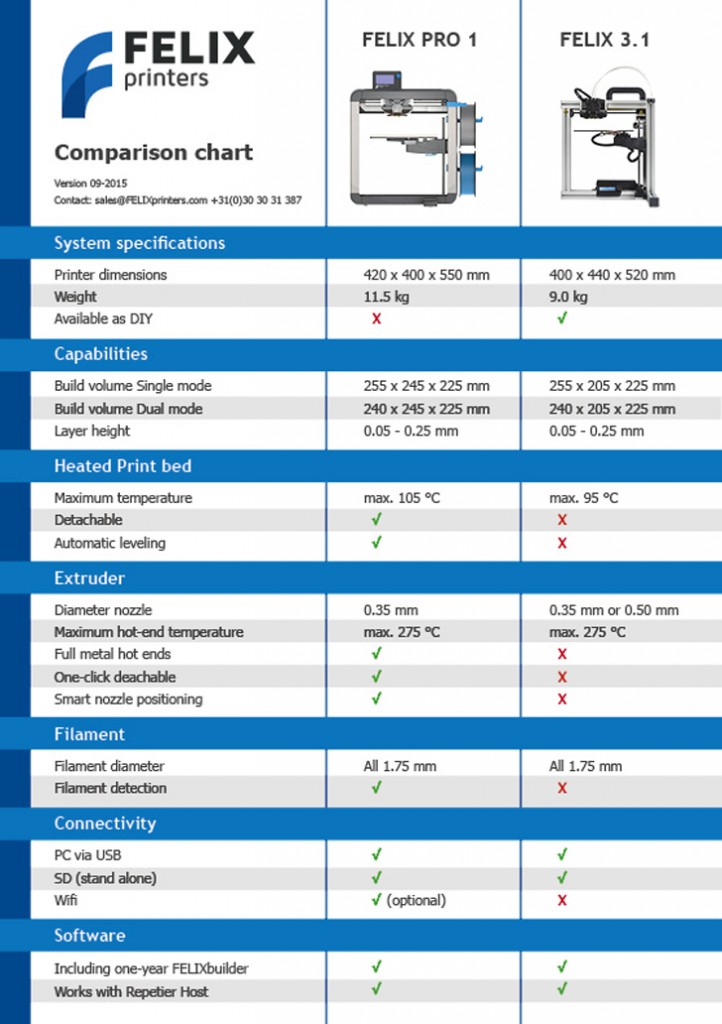

As a follow up to an already solid and popular 3D printer, the FELIX Pro 1 appears to be a powerful, but very user friendly machine. For more information on the FELIX Pro 1, as well as the father-son team behind FELIXprinters, visit their website. And, to see a complete comparison breakdown of the FELIX Pro 1 to the FELIX 3.1, check out the specs below: