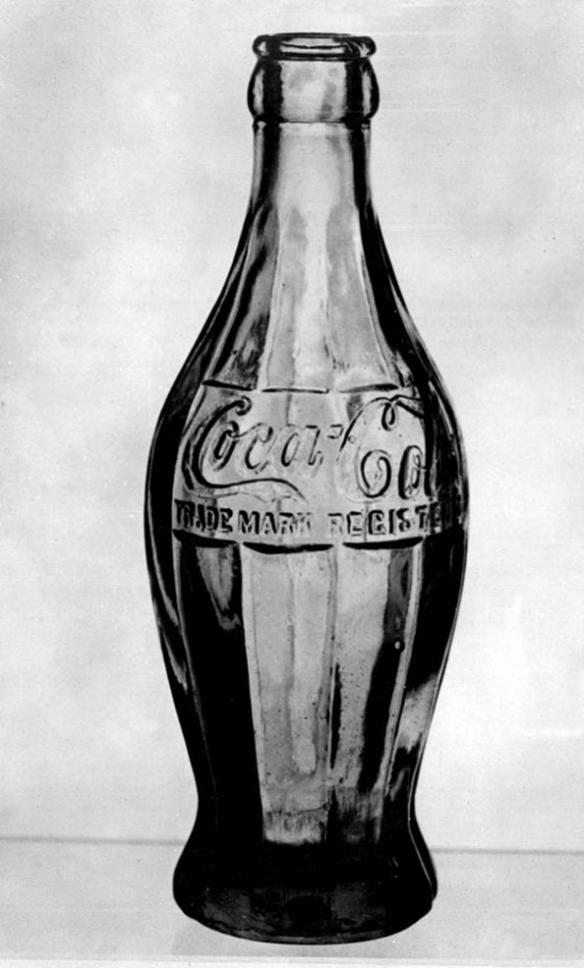

In a product as apparently simple as a Coca-Cola bottle, shape is everything. So, if you are Coke’s biggest bottling facility serving Italy, and you have the opportunity to make an exclusive bottle honoring the 100th anniversary of the iconic 900 ml Coca-Cola Contour bottle, you want to make sure you do it right the first time. And, to get the prototype done quickly, today, you can turn to 3D printing.

That is exactly what Luca Busi, AD of Sibeg, did for the new 0900 Contour bottle, which will be distributed exclusively on the local Sicilian market. It was developed both in celebration for the 100 years that have passed since the first patent of the Contour and as an aggressive commercial initiative, since the family-size bottle will be launched at €0.99, making it perfect for impulse buying.

“I asked my collaborators to get a real feel for the bottle’s shape before we ordered the injection-molded versions and that, of course, led us straight to 3D printing,” Busi explained. “To best give our contribution to the 100 year celebration of the first Contour we wanted to make a new bottle that perfectly reflected the proportions in the bottle’s curves, continuing in what is a century long story which is passed on from generation to generation.”

The original design was developed by Coca-Cola’s technical department; however, getting a real feel for the actual shape before ordering several hundred thousands of bottles can offer significant benefits, even to a company as large as Sibeg, with yearly revenues of over €100 million and production capabilities to cover more than 10% of Coca Cola’s bottling capabilities in Italy.

While in the past these prototyping capabilities were mostly used by companies with intensive prototyping requirements, such as automotive and aerospace manufacturers, the higher capillarization of low cost prototyping services makes it possible even for a bottling company, which only has occasional need for new prototypes, to perform a test print.

Busi turned turned to the local 3D Store Catania, conveniently located only a couple of miles from the facility. “It was the first time we turned to 3D printing to test out a new prototype and we are extremely satisfied with the results both in terms of the speed and quality of the results,” Busi told me. “We certainly intend to implement it again for future bottles. Together with the entire group, we are currently working on the 1.5 liter Fanta bottle and we are eager to consider these new approaches in the bottle’s development.”

Coca-Cola is not new to collaborations revolving around 3D printing and environmental sustainability. Last year the company partnered with 3D Systems’ Chief Creative Officer, singer will.i.am, to introduce the Ekocycle Cube 3D Printer, which uses filament paritally made up of recycled Coke bottles. “We fully share the group’s vision for more sustainable and environmentally sound manufacturing,” Mr. Busi continued. “Our focus for the plant in Sicily has been to pay a lot of attention to recycling and more efficient and streamlined production. I believe 3D printing will continue to play an ever growing role in this respect.”

“We are also very excited for this ‘0900’ operation,” Busi reiterates, adding that “it is unique in all of Europe and, at a price of just €0.99, it will enable more families to enjoy Coca Cola products. We like to think that it could be a small step to restart our local economy while also honoring a long-standing global tradition.” It seems that 3D printing is just the most appropriate way to take a 100-year-old tradition into the future.