Last year, we reported on a project by the European Space Agency to test the possibilities of 3D printing antennas for possible use in space satellites. The project has been steadily progressing, with the ESA reporting on their latest 3D printed prototype, their first dual-reflector antenna.

Engineer Maarten van der Vorst describes device, saying that it could, one day, be used in satellite constellations, which will see smaller satellites coordinating to achieve the performance of larger systems. “This is the Agency’s first 3D-printed dual-reflector antenna,” van der Vorst says. “Incorporating a corrugated feedhorn and two reflectors, it has been printed all-in-one in a polymer, then plated with copper to meet its radio-frequency (RF) performance requirements. Designed for future mega-constellation small satellite platforms, it would need further qualification to make it suitable for real space missions, but at this stage we’re most interested in the consequences on RF performance of the low-cost 3D-printing process.”

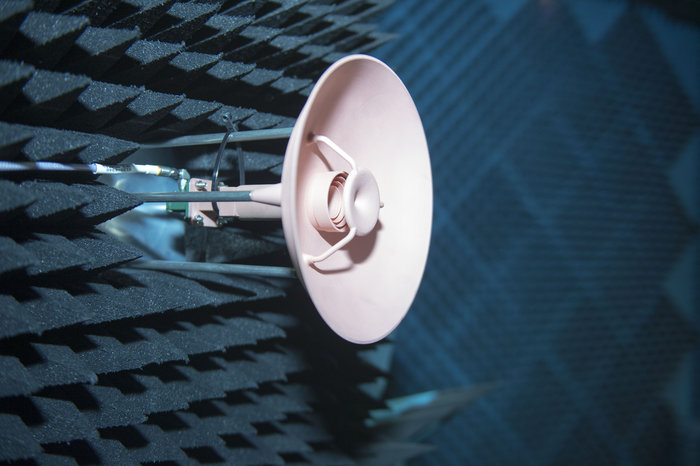

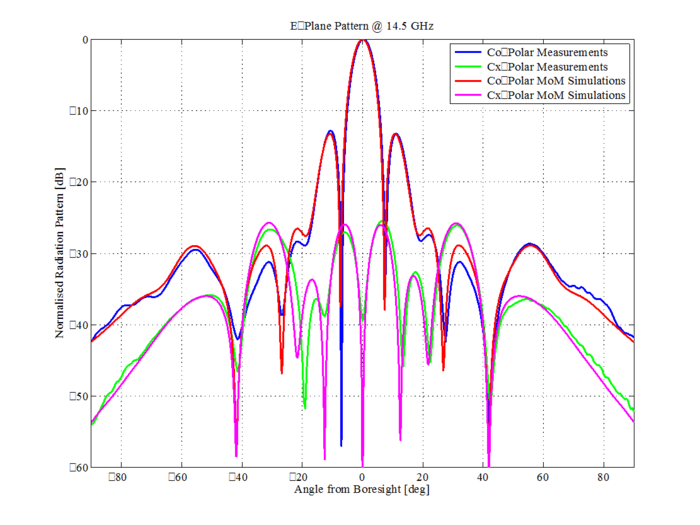

The technical center for the ESA’s Electromagnetics & Space Environment Division is located in Noordwijk, the Netherlands, where it can be isolated from interference, such as outside electromagnetic radiation. Foam walls within are meant to simulate space by absorbing radio signals. Antenna test engineer Luis Rolo speaks to the results of the agency’s testing, explaining, “Although the surface finish is rougher than for a traditionally manufactured antenna, we’re very happy with the resulting performance. We have a very good agreement between the measurements and the simulations. Making a simulation based on a complete 3D model of the antenna leads to a significant increase in its accuracy. By using this same model to 3D print it in a single piece, any source of assembly misalignments and errors are removed, enabling such excellent results.”

Swiss company SWISSto12 has been working on the project, as well, producing the prototypes reported last year. The firm uses a specialty copper-plating process to apply the material to complex objects and have, so far, produced two different antennas for the ESA. There’s still work to do, however, before the technology can be deployed in space. van der Vorst adds, “As a next step, we aim at more complex geometries and target higher frequencies. And eventually we want to build space-qualified RF components for Earth observation and science instruments.”