When my wife and I were shopping for wedding rings, we came to realise just how corrupted our tastes had become, thanks to the customising capabilities offered by web 2.0. As Danielle poured through Pinterest, idealised photos of some of the most unique rings were displayed, giving users unrealistic expectations of what sorts of rings were out there. After all, a one-of-a-kind ring on Pinterest is one-of-a-kind. Don’t get me wrong, we found our dream rings on Etsy, a stunning Victorian-era ring for Danielle and a retro-futuristic, art deco ring for me. But for those unlucky dreamers out there, a customised jewellery designer could help you attain those Pinterest pieces that are just out of reach. As is often coupled with the word “customised” these days, 3D printing is the technology to help you do it.

Founded by Charlie Bakhash in the 1950s, American Pearl began as a traditional jewellery retailer and supplier, dedicated to elegant pearls from around the world. Since then, Charlie’s son, Eddie, has kept the company modern, by creating an extensive online store. While the company maintains its brick-n-mortar in the Diamond District, on 5th Avenue in Manhattan, American Pearl’s website has continued to grow with technological advances. With a combination of proprietary CAD software and 3D printing, the company has brought the production of jewellery made from precious metals and stones into the 21st Century.

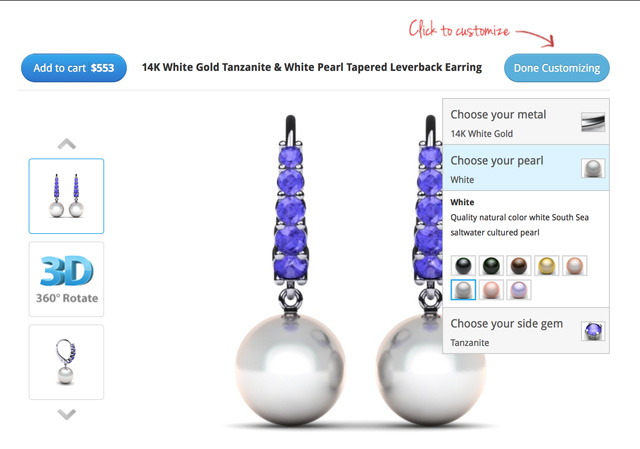

Currently on the American Pearl website, and on the accompanying American Diamond site, customers can personalise select jewellery pieces to fit their needs, using a graphical user interface engineered by Eddie and his company. On a good deal of the products, including pearl and diamond rings and earrings, it’s possible to customise a variety of the jewellery’s features. One can choose specific stones, stone shapes and qualities, to be set into their piece, as well as the type of metal that it’s made from, such as white, rose or yellow gold. With the choice of each stone, a new iteration of your design will be shown, altering the spacing between stones. You can rotate your ring in 3D space or see it modelled on a virtual finger. With select rings, it’s possible to virtualise an engraving into the piece. And, most importantly, the ring size can be altered to your specifications, which will then be reflected in the virtual model as well. Though there is a limit to the customisation that can be achieved on the site, at the moment, the company does have plans for a future GUI that would allow users a much greater freedom of design and create wholly custom pieces of jewellery.

After you’re done selecting your piece, tweaking its metal, gemstones, size and engraving, your job is done. What happens next involves a Solidscape T76 3D printer. Your design is printed in thermoplastic wax for investment casting. A mould is created, a precious metal burns out the wax model, and the foundation for your piece is ready to be fitted with precious gemstones. In addition to the ability to allow for online customisation, this process saves a huge amount of time and money that would have previously been spent with countless hours of wire bending and twisting by hand, thus dropping the price of the jewellery itself. For a promo that demonstrates the process in more detail, watch below:

The company has been using such technology since the mid-to-late 2000’s, with attention drawn to their technological process starting only recently with the 3D printing hype. In addition to manufacturing the lines of rings, bracelets, pendants and earrings you’ll find on their site, American Pearl creates custom pieces upon request. Though Eddie told me that they’d produced art pieces for some of the world’s most renowned artists, he was unable to divulge their names. More important, to Eddie, than who he’d designed for was what this technology would do for the United States: namely, to bring manufacturing back to the US.