Kaiba Gionfriddo was born prematurely in 2011. After 8 months, his lung development caused concerns, although he was sent home with his parents as his breathing was normal. Six weeks later, Kaiba stopped breathing and turned blue. He was diagnosed with tracheobronchomalacia, a long Latin word that means his that windpipe was so weak that it collapsed. He had a tracheostomy and was put on a ventilator – the conventional treatment. Still, Kaiba would stop breathing almost daily. His heart would stop, too. Then, his caregivers 3D printed a bioresorbable device that instantly helped Kaiba breathe. This case is considered a prime example of how customized 3D printing is transforming healthcare as we know it.

Since Kaiba’s story, 3D printing in medicine has been skyrocketing. And the list of objects that have already been successfully printed in this field demonstrates the potential that this technology holds for healthcare in the near future.

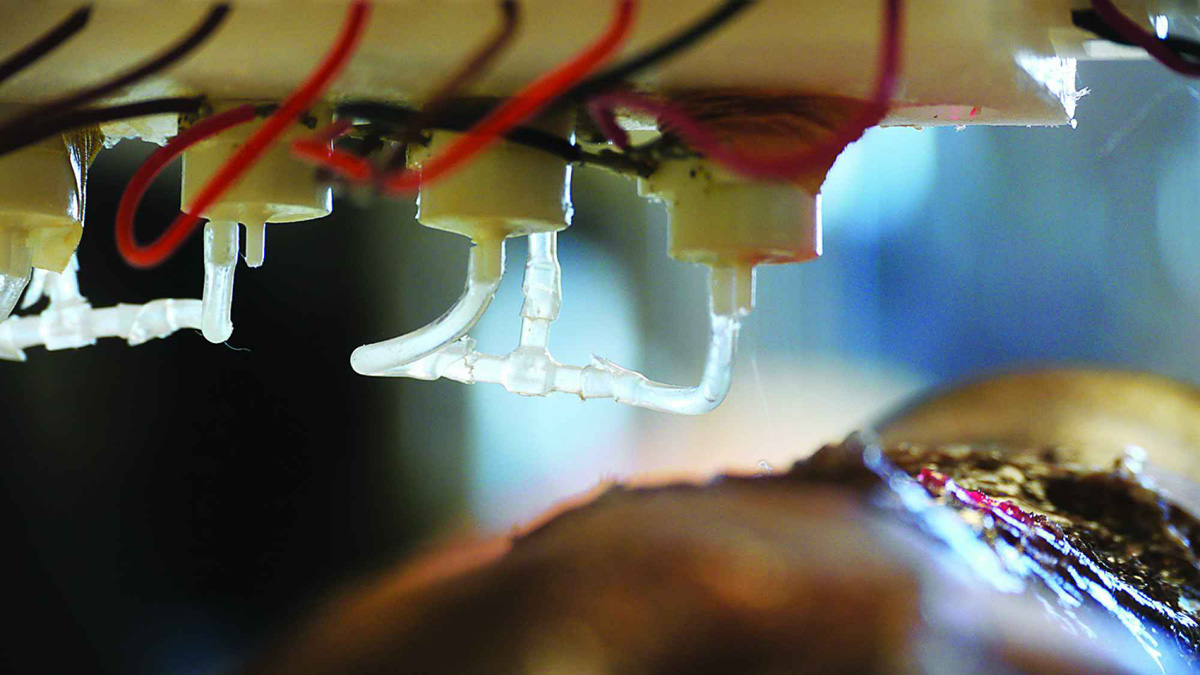

1. Tissues with blood vessels:

Researchers at Harvard University are making great progress in bioprinting blood vessels, a crucial step towards printing tissues with a blood supply. The lab of Dr. Jennifer Lewis designed a custom-built 3D printer and a dissolving ink to create a swatch of tissue containing skin cells interwoven with structural material that can potentially function as blood vessels.

2. Low–Cost Prosthetic Parts:

Creating traditional prosthetics is very time-consuming and destructive, in that any modifications to the prosthetics would destroy the original molds. Moreover, the cost of traditional prosthetics is a significant barrier to those without significant resources. Researchers at the University of Toronto, in collaboration with Autodesk Research and CBM Canada, used 3D printing to quickly produce cheap and easily customizable prosthetic sockets for patients in the developing world, particularly Uganda. Similarly, “Not Impossible Labs” based in Venice, California took 3D printers to Sudan where the chaos of war has left many people with amputated limbs. The organization’s founder, Mick Ebeling, trained locals how to operate the machinery, create patient–specific limbs, and fit these new, very inexpensive prosthetics. This work is also being driven quite significantly by two major organizations, Robohand and E-Nable, whose 3D printable prosthetics have proliferated with wild success.

3. Drugs:

Lee Cronin, a chemist at the University of Glasgow, wants to do for the discovery and distribution of prescription drugs what Apple did for music. In a TED talk Cronin describes a prototype 3D printer capable of assembling chemical compounds at the molecular level. Patients would go to an online drugstore with their digital prescription, buy the blueprint and the chemical ink needed, and then print the drug at home. In the future Cronin suggests that we might sell not drugs but rather blueprints or apps. Progress is already being made in this direction as Louisiana Technical University researchers have printed biocompatible, biodegradable devices for delivering bone cancer medicines.

4. Tailor-made sensors:

Researchers at Washington University in St. Louis have used scans of animal hearts to create printed models, around which, stretchable electronics were wrapped. The silicon device can be peeled off of the printed model and attached onto a human heart for a perfect fit. Though the electronic sensors can detect oxygenation detectors, heart strain strain, and temperature, the next step is to enhance the electronics with multiple sensors, including those that measure acidic conditions to detect blocked arteries.

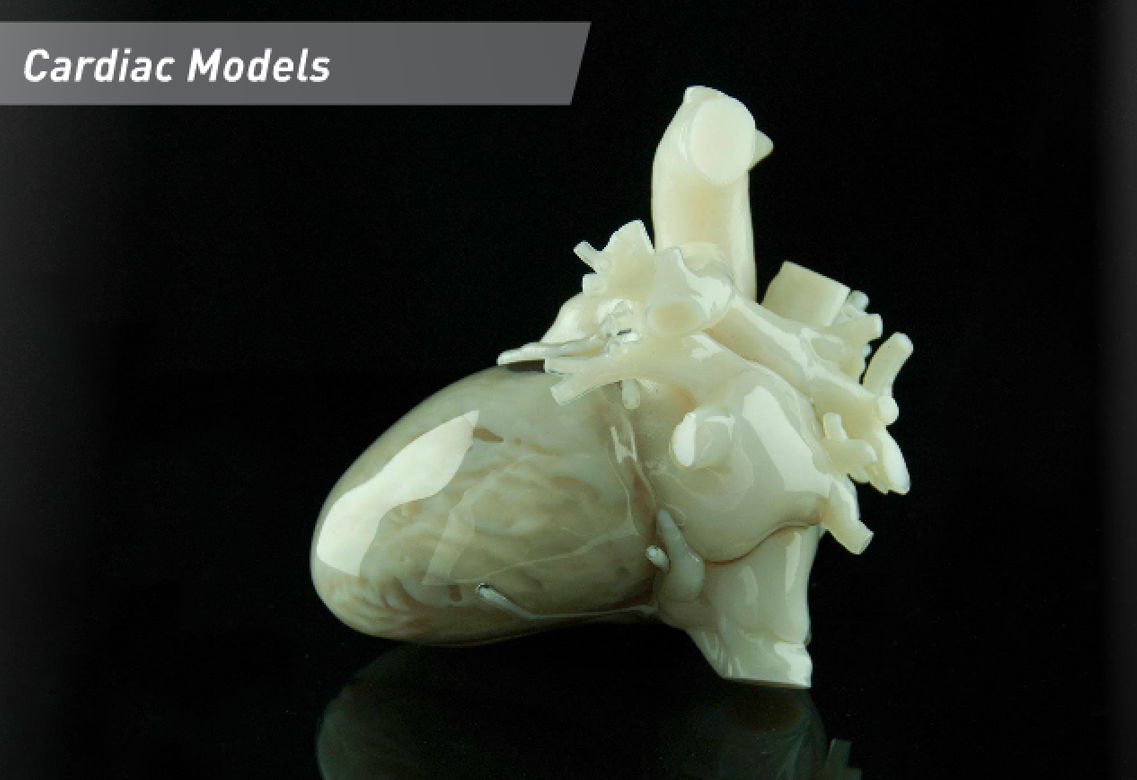

5. Medical Models:

A group of researchers in China and the US have printed models of cancerous tumors to aid discovery of new anti-cancer drugs and to better understand how tumors develop, grow, and spread. Creating patient-specific models from CT and MRI scans expands from medical research into practical application with the ability to prepare doctors for surgeries, thus drastically reducing surgery times. Taking this one step further, there are numerous examples of using medical scan data to 3D print implants tailor-made to the patient.

6. Bone:

In 2011, Professor Susmita Bose, of Washington State University, modified a ProMetal 3D printer to bind chemicals to a ceramic powder, creating intricate scaffolds that promote the growth of bone in any shape. Prof. Bose’s goal is to, one day, be able to implant the bone scaffold with bone growth factors in such a way that the implant is dissolved by natural bone material in even load-bearing bone structures.

7. Heart Valve:

Jonathan Butcher, at Cornell University has printed a heart valve that will soon be tested in sheep. With a dual-syringe machine, he was able to print a combination of alginate, smooth muscle cells, and valve interstitial cells, to control the valve’s stiffness.

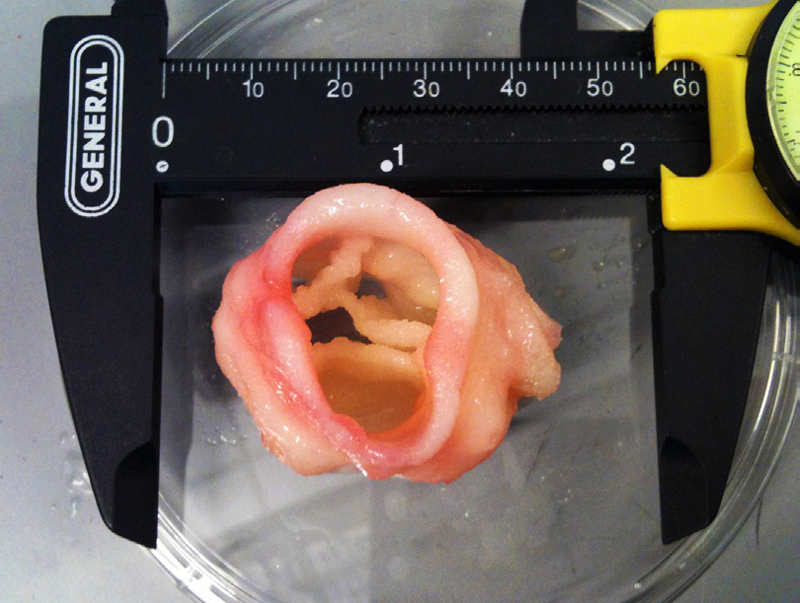

8. Ear cartilage:

Cornell’s Lawrence Bonassar used 3D photos of human ears to create ear molds. These molds were then filled with a gel containing bovine cartilage cells suspended in collagen, which held the shape of the ear while cells grew their extracellular matrix. Bonassar and his team have since gone on to 3D print intervertebral discs to treat major spinal complications, while researchers at Princeton have 3D printed their own collagen ear, this time, with built-in electronic components for superhuman hearing.

9. Medical equipment:

Already, 3D printing is occurring in poverty-stricken areas of the world. Due to the ability to manufacture items that may be difficult or expensive to obtain by traditional means, groups like iLab//Haiti have taken to 3D printing umbilical chord clamps for local hospitals in Haiti.

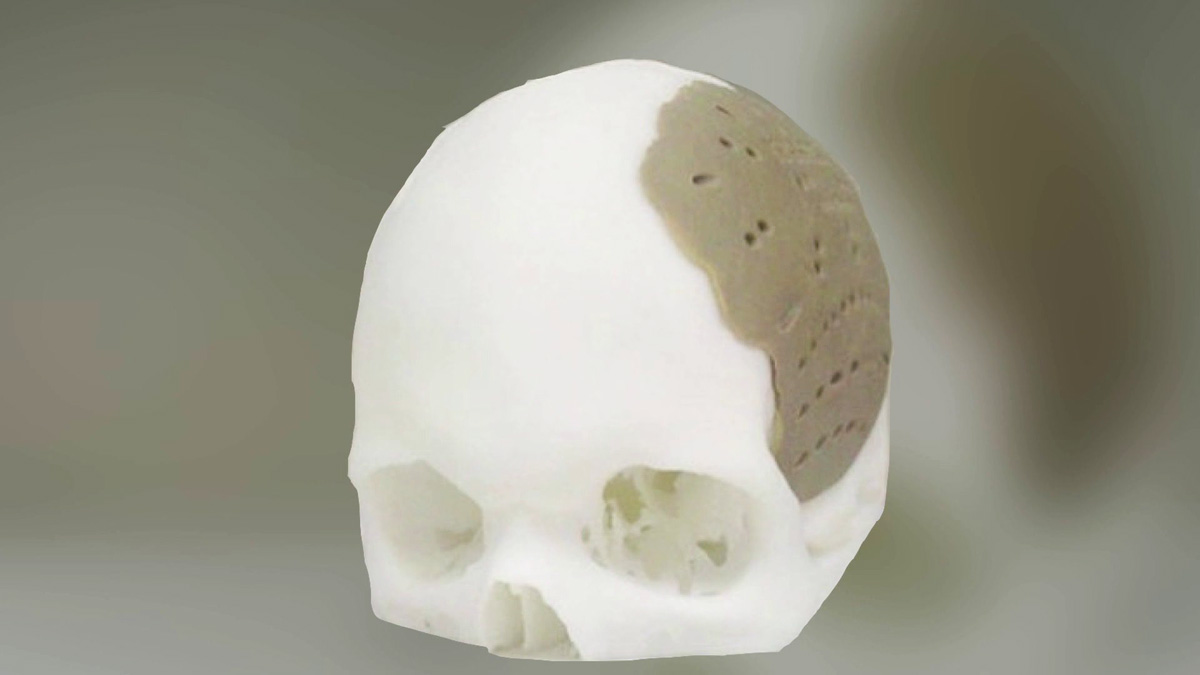

10. Cranium Replacement:

A team of Dutch surgeons at the University Medical Center in Utrecht replaced the entire top portion of a 22 year–old woman’s skull with a customized printed implant made from plastic. This story has been replayed in China, where a man with a crushed skull was given a tailor-made, 3D printed, titanium replacement, and in Slovakia, in which a different man with brain damage received a similar, 3D printed treatment.

11. Synthetic skin:

James Yoo at the Wake Forest School of Medicine in the US has developed a printer that can print skin straight onto the wounds of burn victims. With the ability to scan a wound, the printer can then fabricate the appropriate number of skin layers to fill the wound. Yoo’s research was able to successfully demonstrate the viability of a 10-cm piece of skin transplanted onto a pig and has since been funded by the US Army to use the technology to treat wounded soldiers.

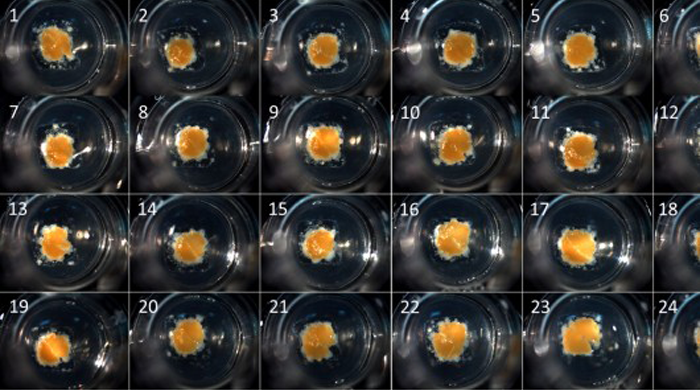

12. Organs:

Organovo recently announced the commercial launch of their bioprinted liver assays, 3D printed liver cells that able to function for more than 40 days. While, at the moment, the product is used for testing new pharmaceuticals, Organovo’s top executives and other industry experts suggest that within a decade we will be able to print solid organs such as liver, heart, and kidney. Hundreds of thousands of people worldwide are waiting for an organ donor; imagine how such a technology could transform their lives.

3D printing is just one of the many revolutionary technologies currently being used in healthcare. You can read more about the use of 3D printing, and much more, in medicine in my recent book, The Guide to the Future of Medicine!