Ever since I got into 3D printing, I have always enjoyed 3D printing gifts for loved ones. It makes for a truly unique and personal way to connect with someone, as the time, effort, and thought involved can truly express how much you care. Because of this, I really love this project that shared with us by Simplify3D. Maker and grandpa Chris Knowlton designed and 3D printed an amazing rocket ship playhouse for his two-year-old grandson. The final product looks as good as something that you’d spend hundreds of dollars for at FAO Schwartz.

The two-foot-tall rocket ship is open-sided and is incredibly detailed. It looks perfect for a two-year-old and has enough variety to keep his grandson Benjamin occupied for a long time. The two-foot rocket is complete with three, interconnected levels. One level is a full control center with a computer, radar screen, flight control, and moonscape views, while the bottom level contains oxygen tanks, another level is outfitted with beds designed for the astronaut models, and each level comes complete with a personalized message for Benjamin. Finally, no moon base is complete without a rover so Knowlton designed a moon rover to go along with the rocket playhouse. Knowlton said that his plan was “to make an open-sided rocket, a moon rover vehicle with trailers, and enough supply items so that my little two-year-old ‘astronaut’ can stock the spaceship for a pretend flight into space and then explore the new worlds in the moon rover.”

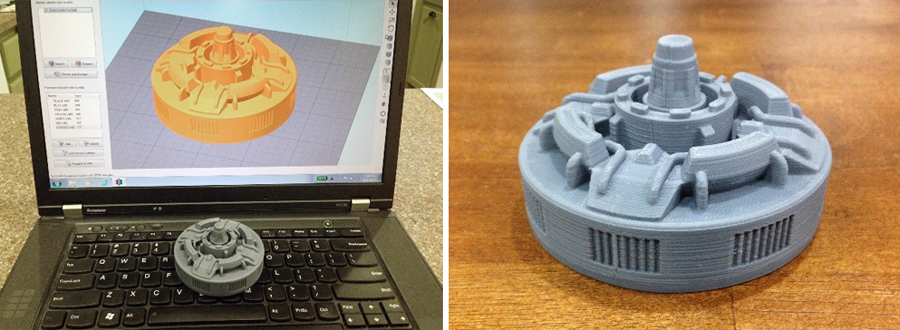

I can’t say enough about both the design as well as the finished product in this project, as it really has a very polished look. Everything, but the astronauts (which were downloaded online), was modeled in Autodesk Inventor. Knowlton printed everything in ABS filament on a Printrbot Metal Simple, which I think is awesome, as this machine is among the most reasonably priced printers on the market and has a modest 6’x6’x6′ build platform. The fact that Knowlton was able to complete a project on this scale and detail goes to show that you don’t need a giant, expensive printer to produce large, multi-colored, and high-quality prints.

In all, the Rocket Playhouse consists of over 195 parts and took about 300 hours of printing time. Knowlton ended up using Simplify3D to slice the models and said, “Like everyone else, I was trying free slicer and host software, but none of them provided me with the control I felt was necessary to print parts at the highest level of quality,” he said. “After getting Simplify3D, the difference in print quality was incredible.”

I couldn’t agree more. Not to sound like a shill, but I had the exact same experience. Last year, I was working on a fairly large and highly detailed print and was having a number issues with print quality. I decided to try Simplify3D and was amazed with the difference in quality, as well as my control over the print. Knowlton definitely made the right choice in slicing software, in my opinion.

Seeing projects like thins make me kind of wish that I was a kid myself but at the same time, I’m excited to have a kid of my own to make things for. It’s amazing to live in an age where we can, quite literally, bring our imaginations to life.