Some argue that the 3D printing market belongs to second movers. If that’s the case, Treed Filaments is one of the companies that is working the hardest to take 3D printing into a new dimension, approaching it from the polymer development side. Dario Pizzigoni, the founder, created Treed as the branch of his industrial plastic extrusion company that is specifically focused on 3D printing materials.

Ever since I met Dario last year, he has come up with hundreds of new formulations and just as many fascinating projects that he and his collaborator Edoardo Longoni are working on. Every time Dario shows me a new material, I ask him if I can write about it, but generally we prefer to wait until the filaments are tested thoroughly and ready to hit the market.

Now, on the occasion of the launch of their new, redesegined website, I went to meet Dario and he showed me some of the new products he has finalized: Carbonium and Longchain nylon for metal replacement; HIRMA (a type of PMMA) for technical 3D printing.

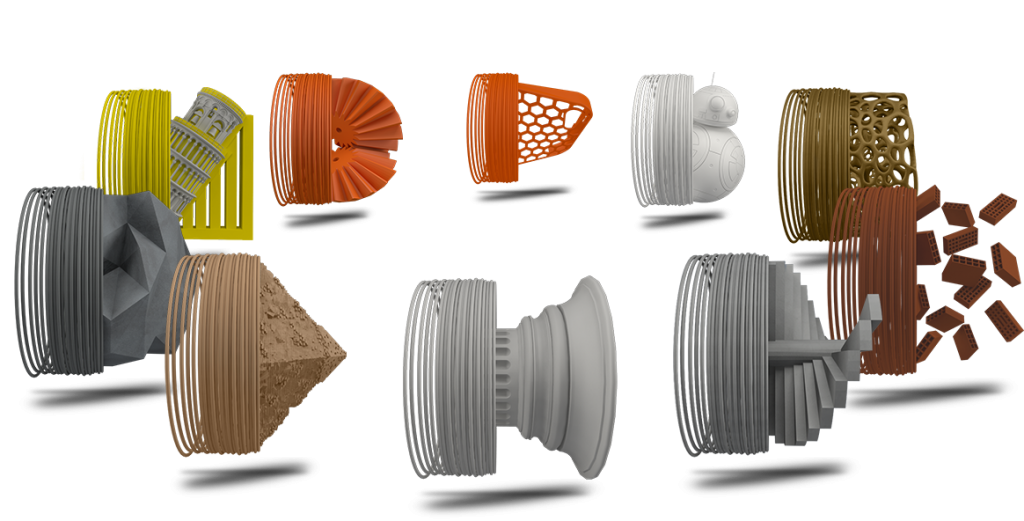

In case you are not yet familiar with Treed, the company focuses on three main areas. One is its Wonderfill line of PLA and ABS. Another is referred to as the Architectural line and includes materials that are mixed with mineral powders such as their Monumental (with marble) and the Caementum (with cement) filaments. The third is the Technical line and includes high performance polymers, such as the ones just announced (and many more to come).

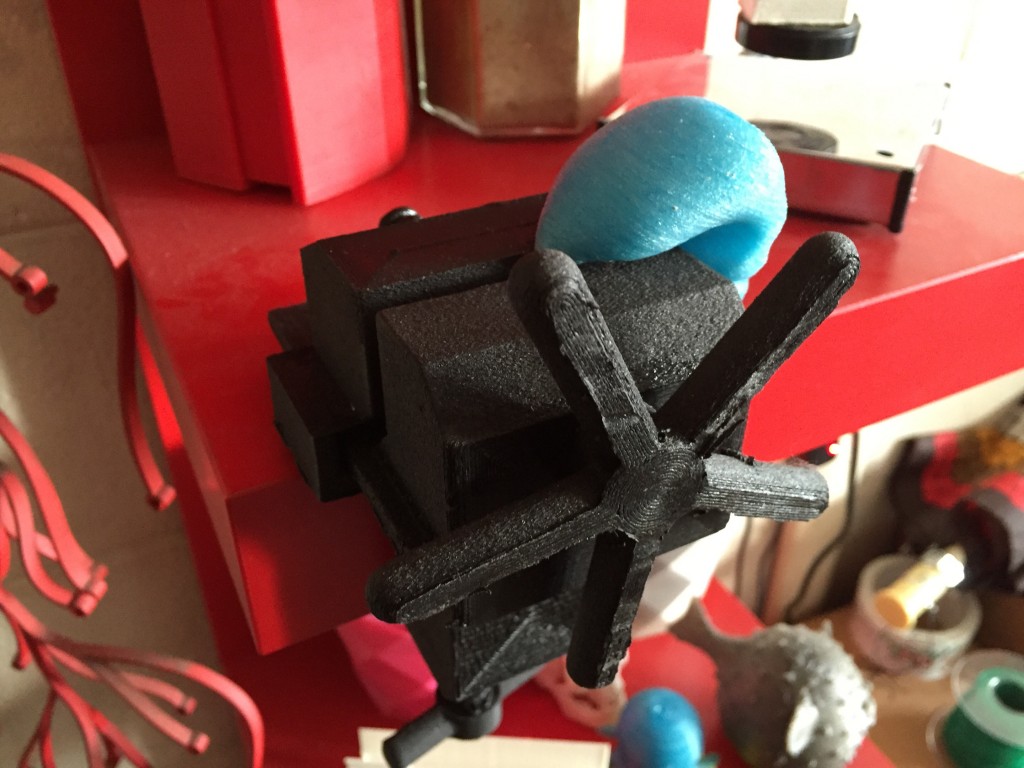

Carbonium is the strongest in Treed’s line of Technopolymers (see photo above). It blends the best features of nylon with carbon fibers (not powder), to offer superior mechanical properties, including low thermal expansion, static electric dissipation, good impact resistance and electromagnetic shielding. Contrary to most nylons, it also has very low hygroscopy and it is stronger than glass fiber reinforced PA.

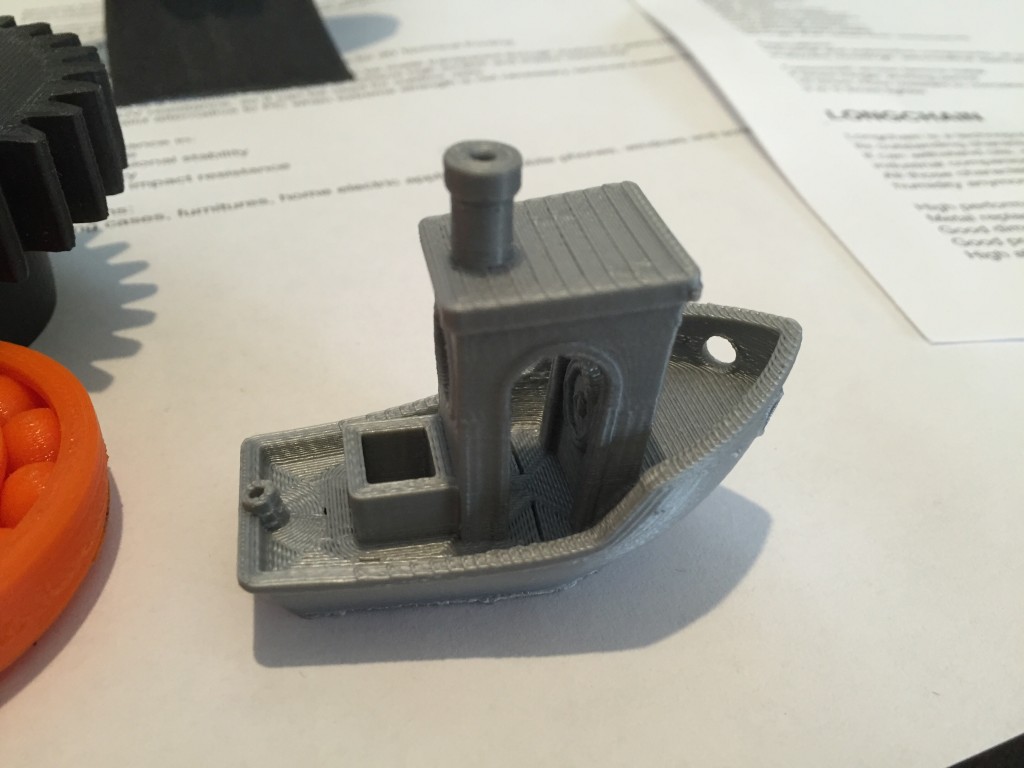

The Longchain is nylon, however it is strictly PA12. This material is made to withstand oils, electricity, high and low temperatures, pressures. It also has a very low hygroscopy index and a working temperature range between -20°C and 115°C. Both these materials can be used for metal replacement applications.

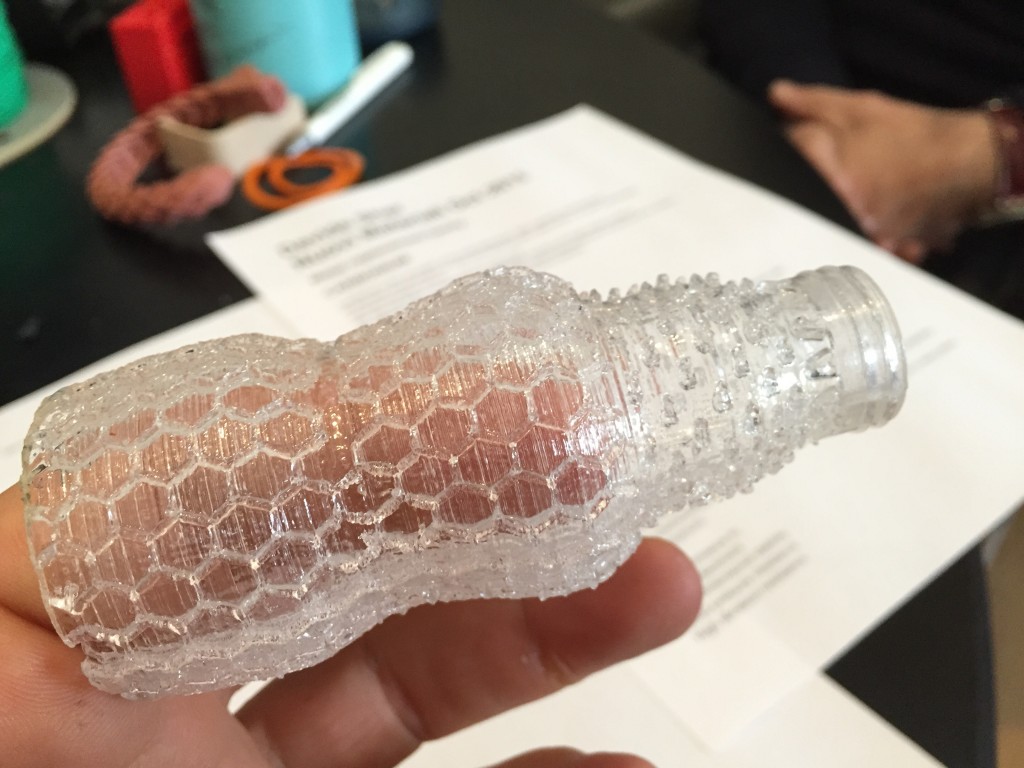

The third new addition is HIRMA, a lightweight thermoplastic that can be made to be highly transparent through acetone or resin treatments. It is basically a modified PMMA that is more scratch and impact resistant. It also does not suffer too much from UV rays and it is fit for outdoor use.

One of the reasons for creating the new website is that Treed now has the production capabilities and the variety to look for new partners and resellers. The company is constantly reviewing new applications, so if you are a filament dealer wanting to further stand out from the increasing competition, this might be an opportunity growing on Treed.